Thin film packaging structure and preparation method thereof, and display panel

A thin-film packaging and substrate technology, which is used in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve problems such as intrusion and packaging failure, and achieve the effects of easy operation, improved packaging performance, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

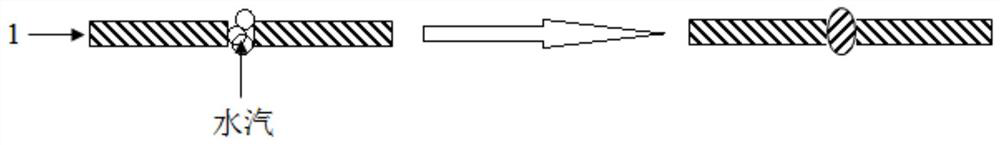

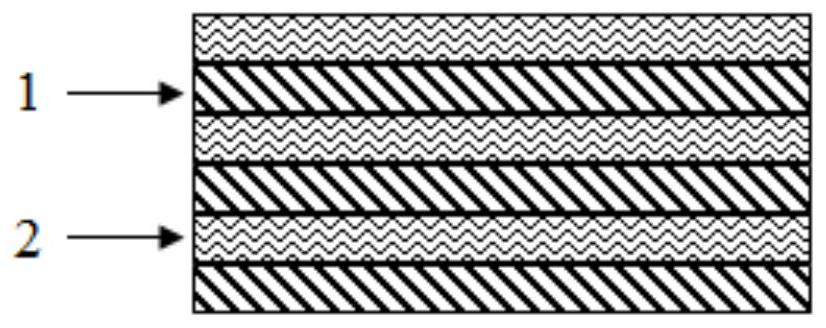

[0055] In order to obtain the above thin film encapsulation structure, the embodiment of the present application also provides a preparation method of the thin film encapsulation structure, the preparation method of the thin film encapsulation structure includes the following steps of preparing an inorganic layer:

[0056] S01, performing film-forming treatment on the inorganic slurry to obtain an inorganic layer;

[0057] Wherein, the inorganic slurry includes a water-swellable material or a precursor for forming the water-swellable material, and the water-swellable material includes at least one of sodium bentonite, nano-scale silica gel, and ettringite.

[0058] In the preparation method of the thin film encapsulation structure provided in the embodiment of the present application, the inorganic slurry including the water-absorbing swellable material or the precursor used to form the water-absorbing swellable material is subjected to film-forming treatment, so as to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com