Temperature-resistant high-voltage cable and preparation process thereof

A high-voltage cable and preparation process technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as unsatisfactory fire prevention capabilities, increased cell resistance, and elevated cell temperature, so as to reduce temperature, Reduced resistance, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The following description of at least one exemplary embodiment is merely illustrative in nature and in no way taken as limiting the invention, its application or uses.

[0035] To keep the following description of the embodiments of the present invention clear and concise, detailed descriptions of known functions and known components are omitted from the present invention.

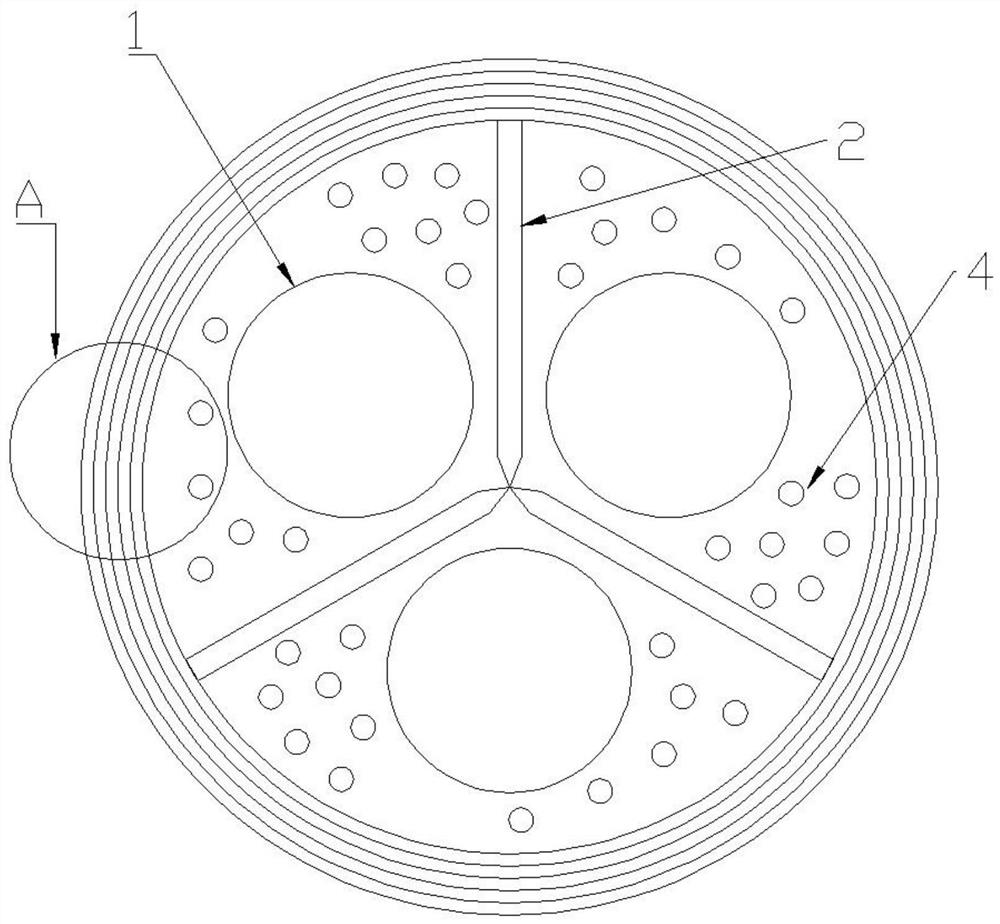

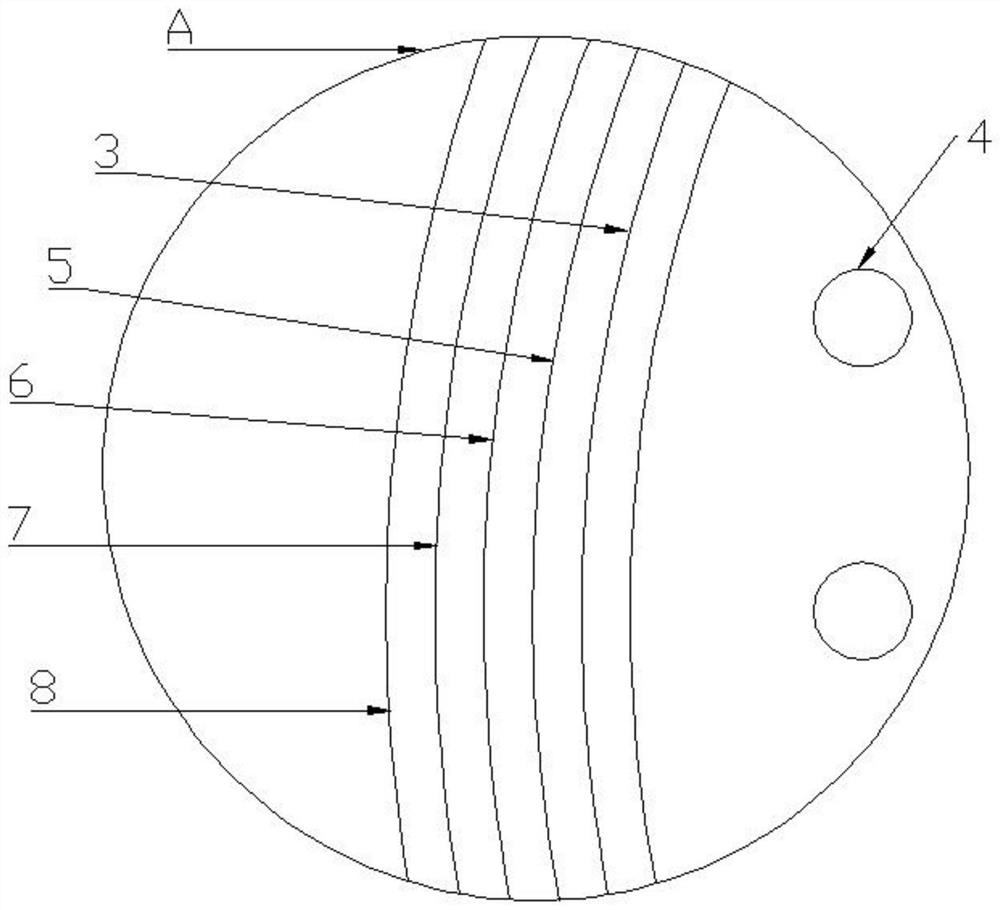

[0036] see Figure 1-3 As shown, a temperature-resistant high-voltage cable is provided in this embodiment, including: a plurality of high-voltage electric cores 1 and a plurality of thermally conductive silicone grease insulating plates 2, and one side of the plurality of thermally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com