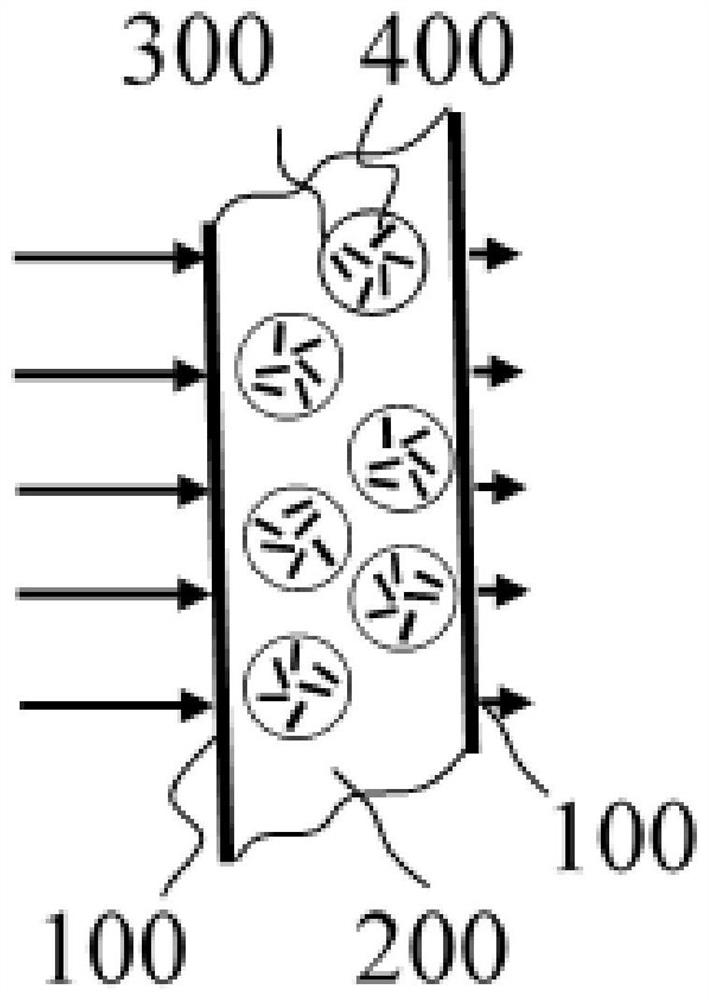

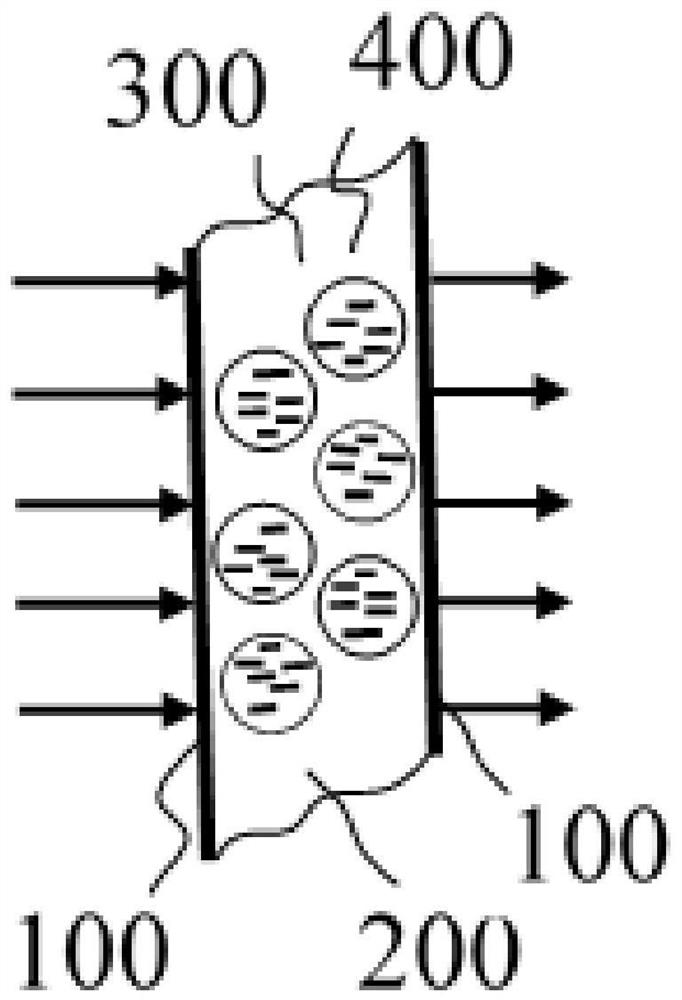

Gray-tone light valve and application thereof

A technology of light valves and keynotes, applied in optics, nonlinear optics, instruments, etc., can solve the problems of limited nanoparticle light valve device application, development obstacles, and restriction of customer choice motivation, etc., to achieve good application prospects and good technical effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Preparation of gray solid particles

[0125] Iodine (component A), metal halides (component B), nitrogen-containing heterocyclic carboxylic acid or ester (component C), and modified cellulose (component D);

[0126] The feeding mass ratio of each component is A component: B component: C component: D component is 1.5:1.0:1.0:1.6.

[0127]Add 30 grams of isoamyl acetate solution containing 21.2wt% nitrocellulose (1 / 4sec SS) to a 250 milliliter three-necked round bottom glass flask, 6 grams of I 2 , 70 g isoamyl acetate, 3.9 g anhydrous PbI 2 , and heated to 42°C. Wait I 2 After dissolving, add 6 g of n-propanol, 0.8 g of distilled water, and 4 g of 2,5-pyrazinedicarboxylic acid dihydrate into a three-necked round-bottomed glass flask. The reaction was heated and stirred at 42° C. for 4 hours, and then cooled naturally.

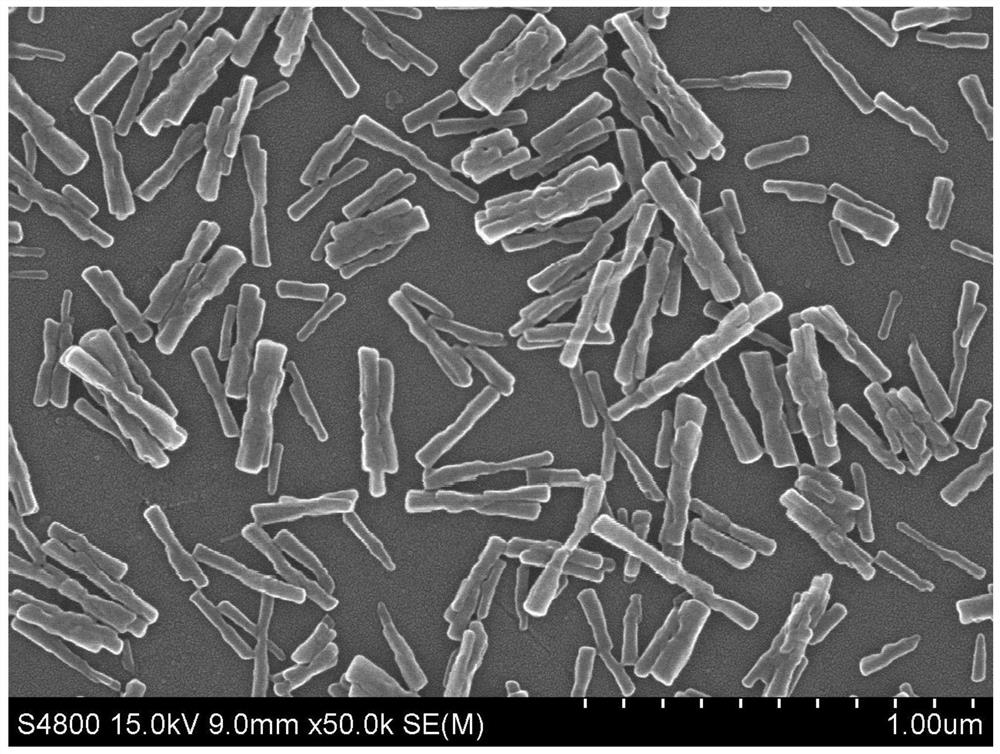

[0128] The reaction solution was centrifuged at 1350G for 0.5 hour to remove large particulate products. The supernatant was centrifuged at 18000...

Embodiment 2

[0134] Preparation of black solid particles

[0135] According to the method of [Example 1], only with 5.0 grams of anhydrous CdI 2 , instead of 3.9 g of anhydrous PbI 2 , heated and stirred at 46° C. for 2 hours, and the mass ratio of each component was A component: B component: C component: D component was 1.5: 1.25: 1.0: 1.57.

[0136] SEM characterization results show that the black solid particles have a particle length of 365 nm, a particle width of 68 nm, and a particle aspect ratio of 5.4. The resulting suspension of black solid particles is called LCP-2.

Embodiment 3

[0138] Preparation of gray solid particles

[0139] According to the method of [Example 1], only 6 grams of isopropanol is used instead of 6 grams of n-propanol, and the reaction is heated and stirred at 50 ° C for 3 hours, and the mass ratio of each component is A component: B component: C Component: D component is 1.5:0.975:1.0:1.57.

[0140] SEM characterization results show that the gray solid particles have a particle length of 303 nm, a particle width of 52 nm, and a particle aspect ratio of 5.8. The resulting suspension of gray solid particles (referred to as LCP-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com