Oil heating single cabinet type battery vacuum intelligent drying equipment and drying method

A drying equipment and single-cabinet technology, which is applied to oil heating single-cabinet battery vacuum intelligent drying equipment and drying fields, can solve the problems of low battery efficiency, low efficiency, and high failure rate of heating plates, so as to improve heat utilization efficiency, The effect of reducing heat energy waste and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

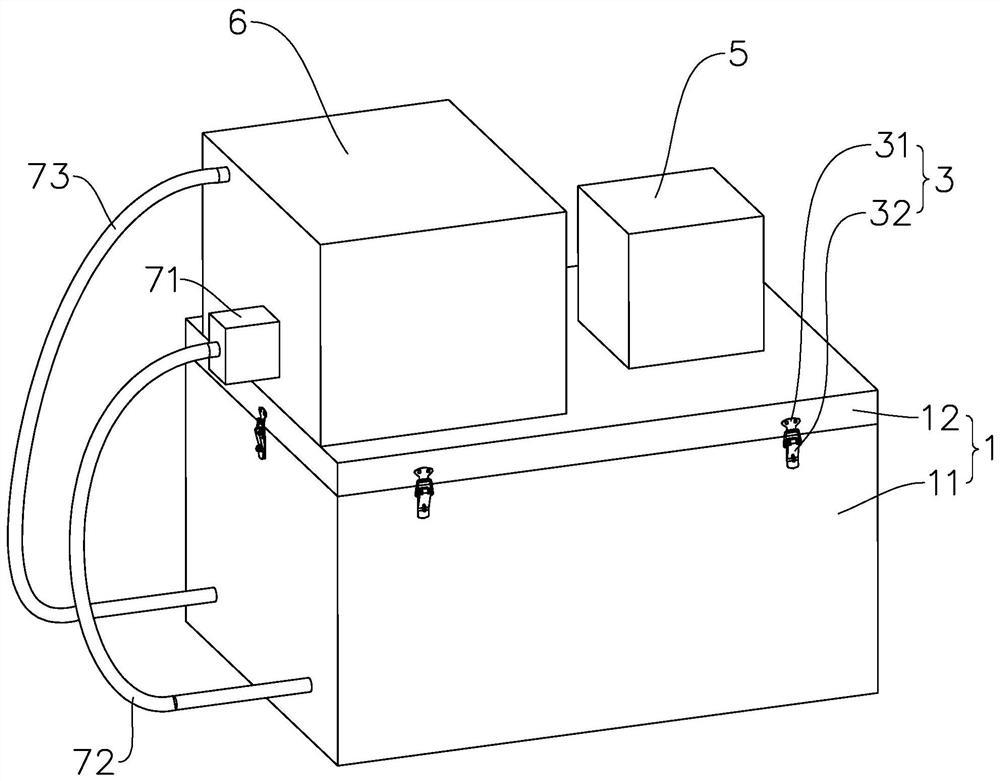

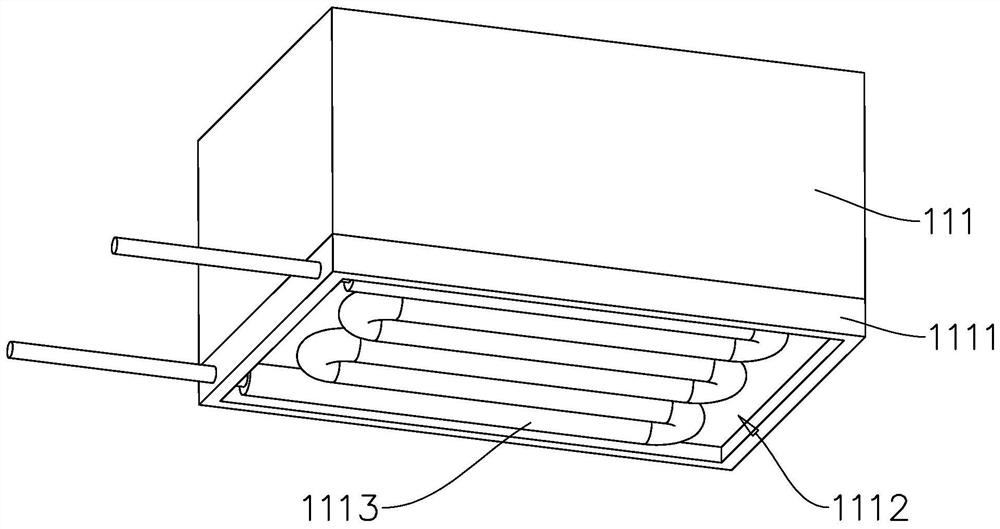

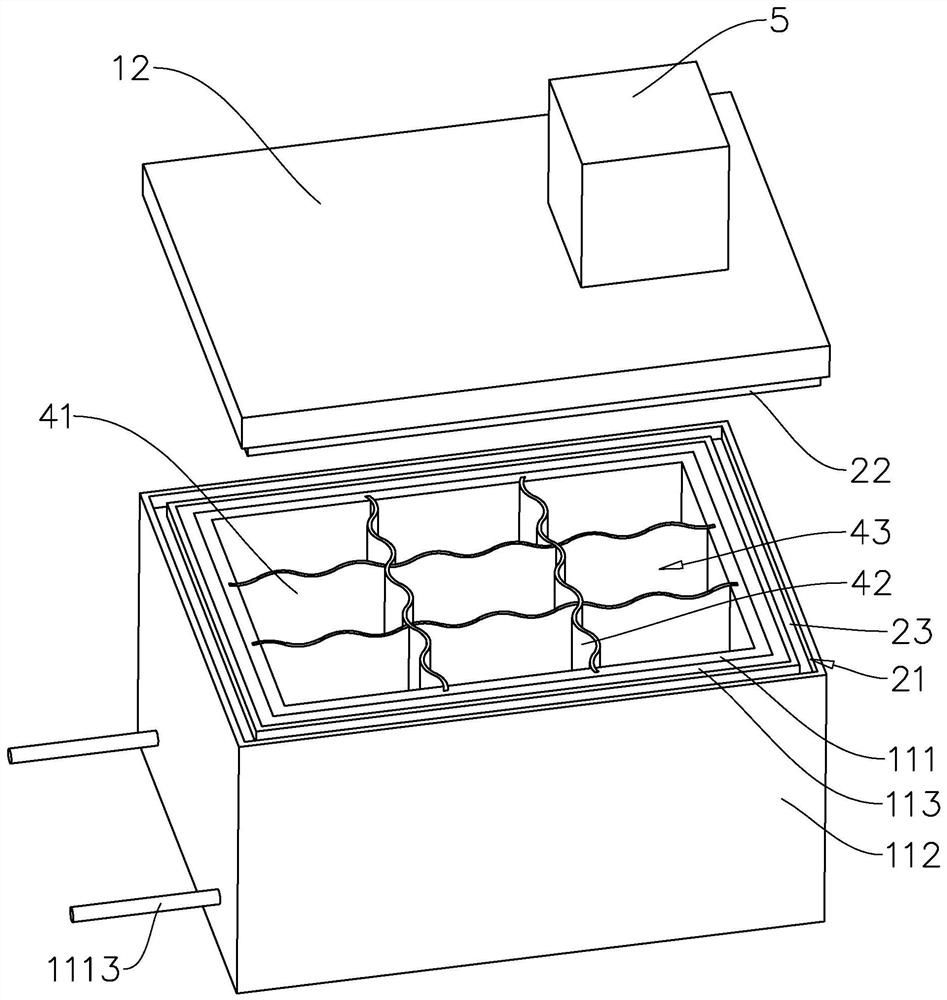

[0042] The embodiment of the present application discloses an oil heating single-cabinet battery vacuum intelligent drying equipment, refer to figure 1 and figure 2 , including a drying box 1, a vacuum device and a heating oil tank 6. The drying box 1 includes a bottom box 11 and a top cover 12. The bottom box 11 includes an inner box 111. The inner box 111 is a square tube with an open top and a closed bottom. The inner box 111 includes a heat conducting plate 1111 and four inner plates. The two inner plates are vertically fixed to the four sides of the heat conduction plate 1111 respectively, and the bottom surface of the heat conduction plate 1111 is embedded with a heat conduction pipe 1113 , and the heat conduction pipe 1113 is in the shape of a serpentine coil. Specifically, the bottom surface of the heat conduction plate 1111 is provided with an installation groove 1112, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com