Lifting components and washing machines

A component and lifting rib technology, applied in the field of washing machines, can solve the problems of clothing wrinkle, wear or space volume that cannot be well balanced, low washing and drying efficiency of washing machines, simple structure, etc., so as to improve the wetting speed and reduce washing The effect of energy consumption, reducing the chance of entanglement or knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

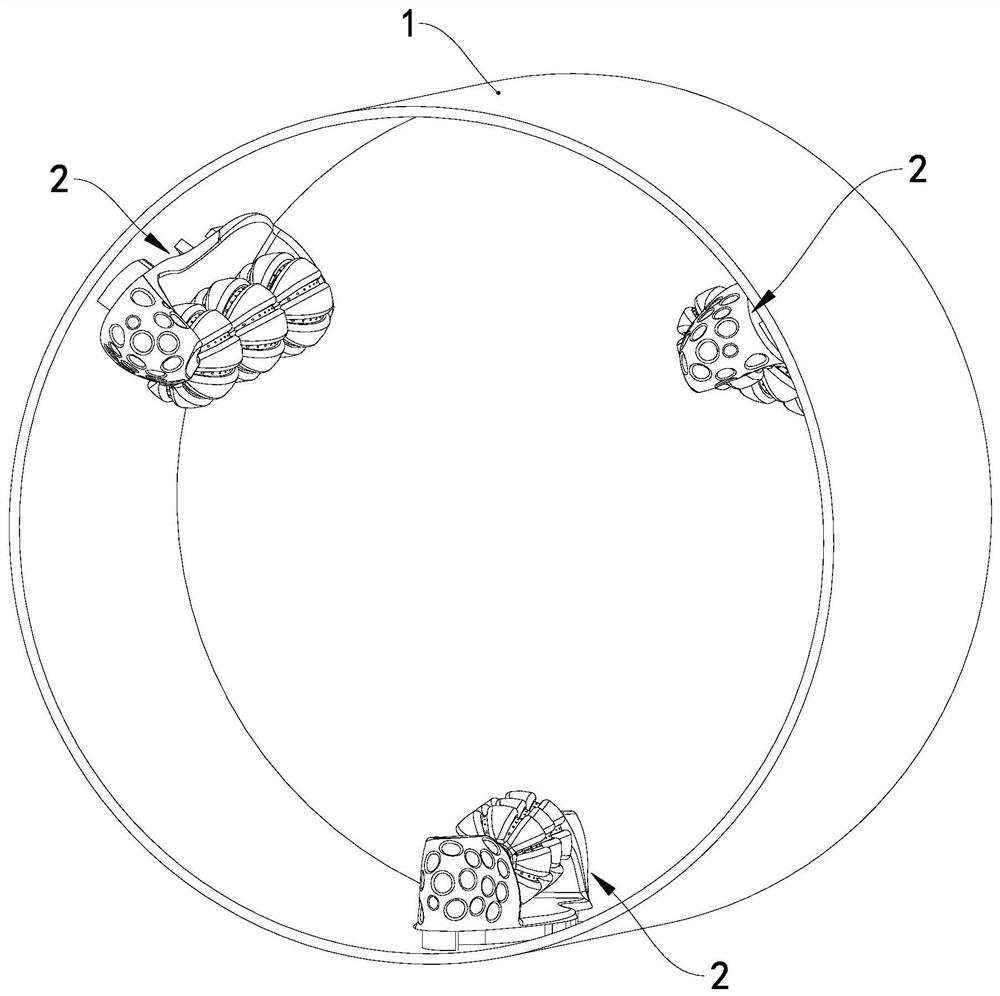

[0034] see figure 1 , the washing machine includes a body and a drum 1 arranged inside the body. In order to improve the clothes lifting and shaking ability of the washing machine in this embodiment, and improve the cleaning effect of clothes, thereby improving washing efficiency, reducing washing time, and reducing washing energy consumption, this embodiment The inner wall surface of the drum 1 of the washing machine is provided with multiple sets of lifting assemblies 2, and the multiple sets of lifting assemblies 2 are evenly distributed in the circumferential direction of the drum 1. Through the function of the lifting assemblies 2, the laundry lifting and shaking ability of the washing machine can be improved, and Improve the cleaning effect of clothes, thereby improving washing efficiency, reducing washing time and water and power consumption.

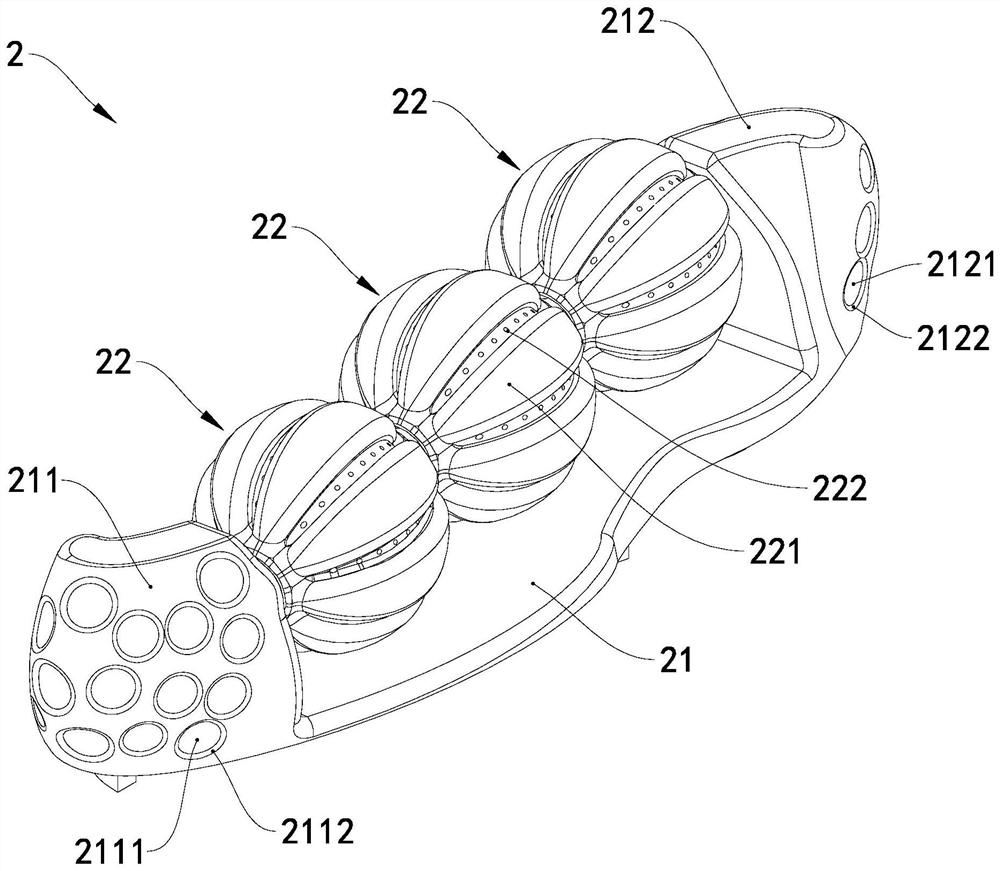

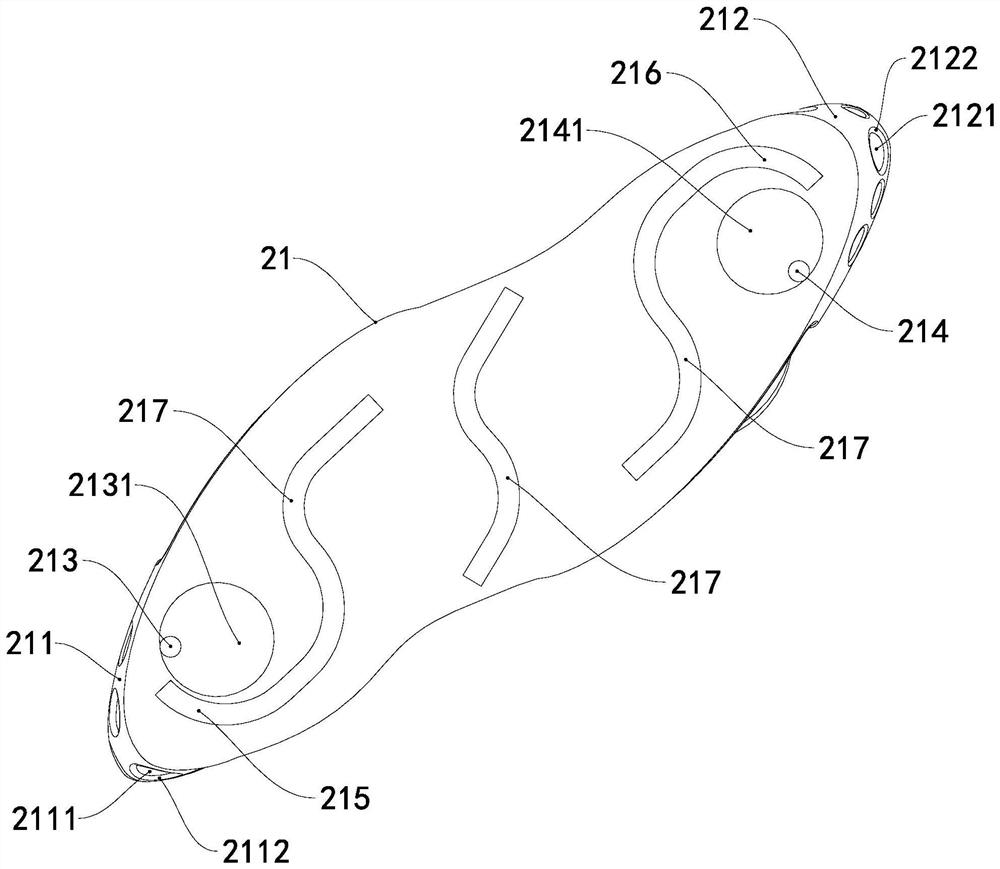

[0035] see Figure 2 to Figure 7 The lifting assembly 2 of this embodiment includes a base 21, a hollow connecting shaft 23 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com