S-doped Sn oxide catalytic electrode and preparation and application thereof

A technology for catalytic electrodes and oxides, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve problems such as leakage hazards, environmental problems, global warming, etc., and achieve the effects of increased selectivity, good catalytic reduction of CO2, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

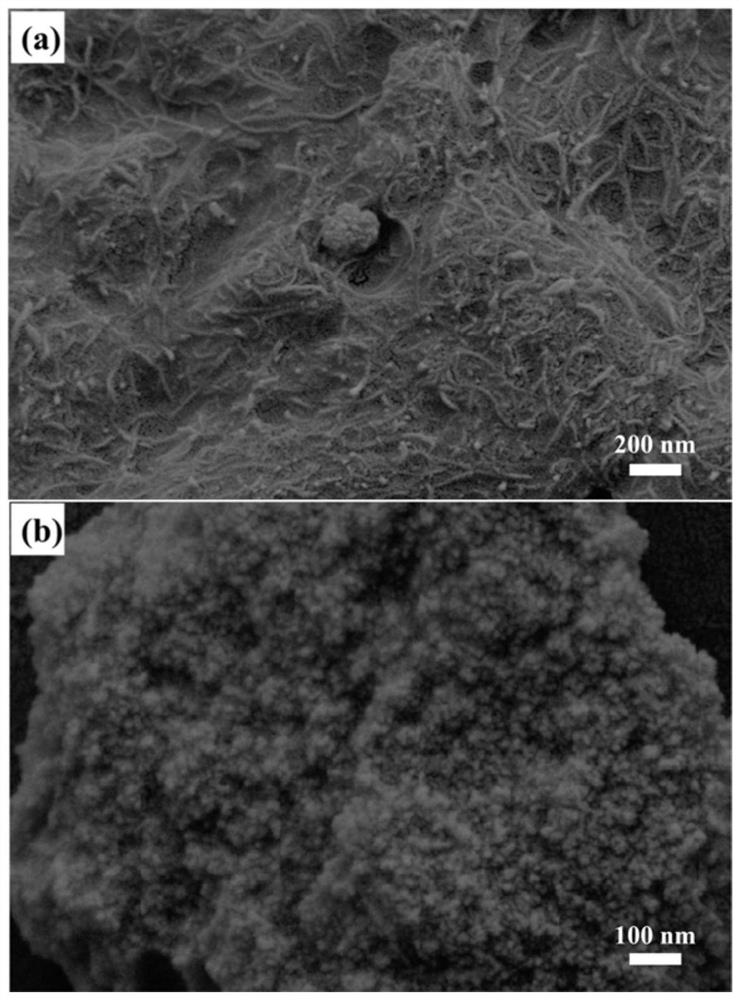

[0036]1. S-SnO 2 Preparation methods of nanomaterials:

[0037] 1) Mix 0.2mol NaOH, 0.01mol SnCl 4 ·5H 2 O and 0.005mol Na 2 S 2 o 3 ·5H 2 O was mixed and ground for 10 min, left to age for 3 h, and then transferred to an oven and heated at 150 °C for 1 h to obtain a precursor mixture.

[0038] 2) The obtained precursor mixture was stirred and soaked in deionized water for 1 h, and the obtained sample was centrifuged and washed 3 times with deionized water, and finally dried at 100° C. to obtain a yellow sample powder.

[0039] 2. S-SnO 2 Preparation method of / MWNTs / sponge electrode:

[0040] 1) Preparation of stock solution: Weigh 0.4g of multi-walled carbon nanotubes, 4g of sodium dodecylbenzenesulfonate and 0.1g of the above-mentioned S-SnO 2 The nanomaterials were uniformly dispersed in 100mL of ethylene glycol, stirred for 1h, and ultrasonicated for 1h for later use.

[0041] II) Soaking. The first soaking: soak 4mL of the stock solution onto the sponge, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com