Non-equal-atomic-ratio high-entropy alloy and method for preparing wire by using same

A high-entropy alloy and atomic ratio technology, applied in the field of metal materials and their preparation, can solve the problems of complex preparation methods, long cycle times, and uneven composition of high-entropy alloys, and achieve simple preparation processes, reduced costs, and excellent wire forming effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

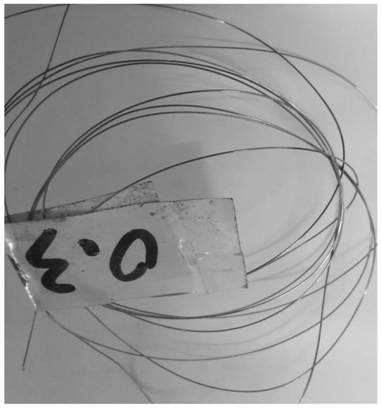

Image

Examples

Embodiment 1

[0026] Alloy composition design and preparation

[0027] A non-isoatomic ratio high-entropy alloy Fe a mn b Cr c Ni d , a, b, c, d respectively represent the atomic percentage of the corresponding metal element, a=35, b=10, c=20, d=35.

[0028] Non-equiatomic ratio high-entropy alloy wire, its preparation method comprises the following steps:

[0029] (1) According to Fe 35 mn 10 Cr 20 Ni 35 Preparation of bulk metal particles containing Fe, Mn, Cr, Ni;

[0030] (2) repeatedly smelting the metal block particles prepared in step (1) at least 3 times in a vacuum induction melting furnace to ensure the uniformity of the alloy composition;

[0031] (3) Cast the alloy smelted in step (2) into an ingot, set the temperature at 1000° C. for 12 hours in a high-temperature heat treatment furnace for homogenization treatment, and then take out the water and quench to normal temperature;

[0032] (4) performing hot swaging on the homogenized heat-treated alloy ingot in step (3) ...

Embodiment 2

[0036] Alloy composition design and preparation

[0037] A non-isoatomic ratio high-entropy alloy, Fe a mn b Cr c Ni d , a, b, c, d respectively represent the atomic percentage of the corresponding metal element, a=35, b=10, c=20, d=35.

[0038] Non-equiatomic ratio high-entropy alloy wire, its preparation method comprises the following steps:

[0039] (1) According to Fe 35 mn 10 Cr 20 Ni 35 Preparation of bulk metal particles containing Fe, Mn, Cr, Ni;

[0040] (2) repeatedly smelting the metal block particles prepared in step (1) at least 3 times in a vacuum induction melting furnace to ensure the uniformity of the alloy composition;

[0041] (3) Cast the alloy smelted in step (2) into an ingot, set the temperature at 1000° C. for 12 hours in a high-temperature heat treatment furnace for homogenization treatment, and then take out the water and quench to normal temperature;

[0042] (4) performing hot swaging on the homogenized heat-treated alloy ingot in step (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com