System for mechanically atomizing and evaporating wastewater and method thereof

A mechanical atomization and wastewater technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high cost, high atomization energy consumption, and high price, and achieve quick results, Low cost and low impact on the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

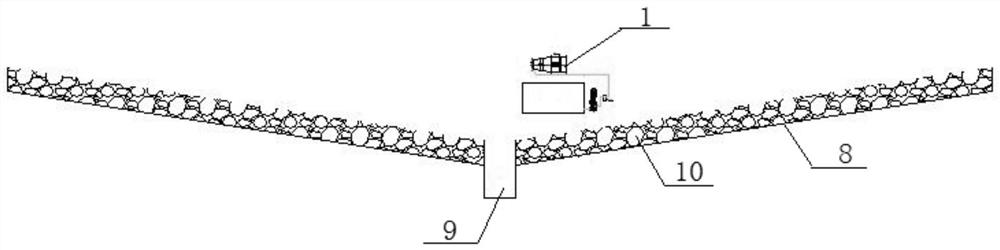

[0041] A system for mechanically atomizing and evaporating waste water provided in this embodiment has a structure such as Figure 1-2 As shown, it includes a mechanical atomization evaporation device 1 and an anti-seepage device, and the mechanical atomization evaporation device 1 is arranged on the anti-seepage device, wherein:

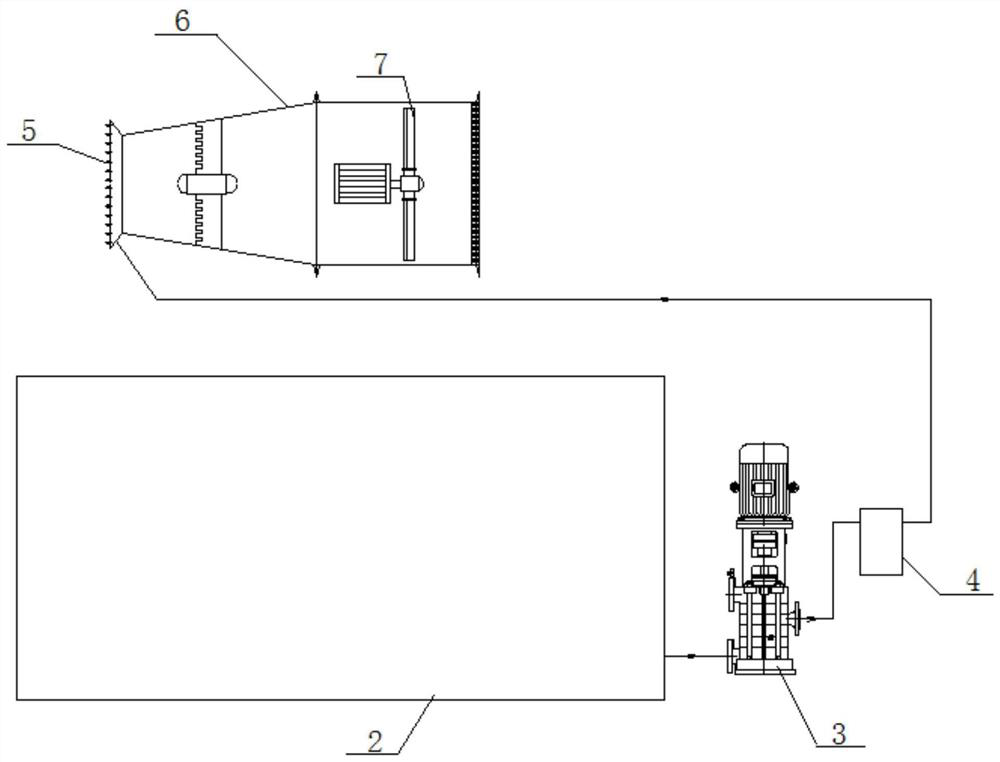

[0042] The mechanical atomization evaporation device 1 includes a water tank 2, a booster pump 3, a filter 4 and a sprayer. The outlet of the water tank 2 is connected to the inlet of the filter 4 through a pipeline and the booster pump 3, and the outlet of the filter 4 Connected to the nebulizer through the pipeline;

[0043]The sprayer is composed of atomizing nozzle 5 and air supply mechanism. The atomization nozzle 5 adopts the standard solid conical nozzle in the prior art. The air supply mechanism includes the air cylinder 6 and the axial flow fan 7 installed in the air cylinder 6. , the atomizing nozzle 5 is arranged at one end of the air cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com