Vertical anaerobic fermentation tank

An anaerobic fermentation tank, vertical technology, applied in the field of vertical anaerobic fermentation tanks, can solve the problems of heavy weight of mixing, inability to mix repeatedly, different materials, etc., and achieve the effect of reducing the rotational force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

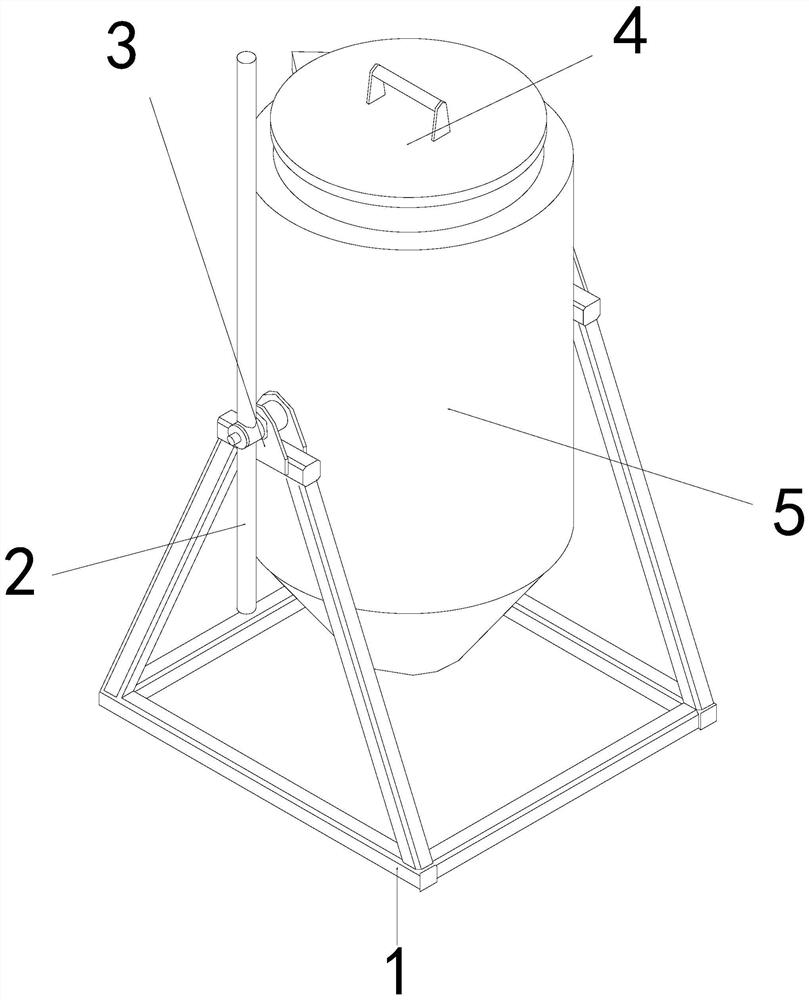

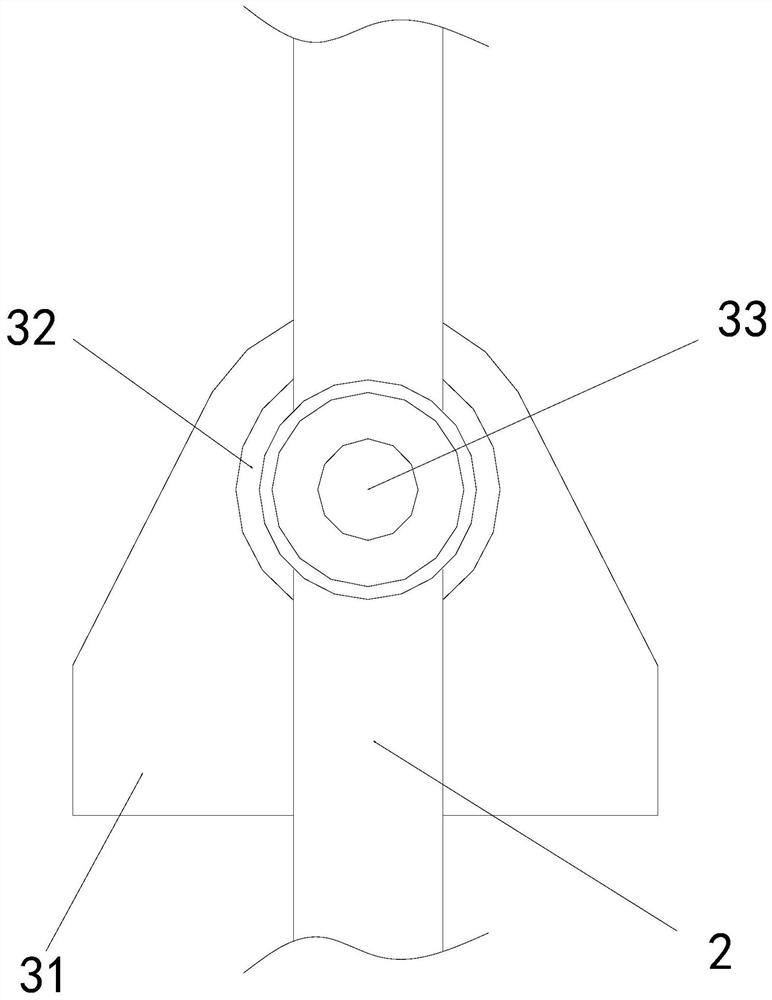

[0025] as attached figure 1 To attach Figure 4 As shown, the present invention provides a vertical anaerobic fermentation tank, the structure of which includes a support frame 1, a balance bar 2, a rotating mechanism 3, an end cover 4, and a tank body 5. The outer wall of the middle section of the balance bar 2 is nested and engaged with the The inner wall of the front end of the rotating mechanism 3, the inner lower end of the rotating mechanism 3 is fixed to the inner wall of the upper end of the support frame 1 by screws, the lower end of the end cover 4 is fixed to the upper end of the tank body 5 through buckles, and the front and rear ends of the tank body 5 are movably engaged Between the rotating mechanisms 3, there are two rotating mechanisms 3, which are relatively arranged on the outer walls of both ends of the tank body 5. After the rotating mechanisms 3 set up at both ends are assembled with the tank body 5, the two ends of the tank body 5 When rotating, the rot...

Embodiment 2

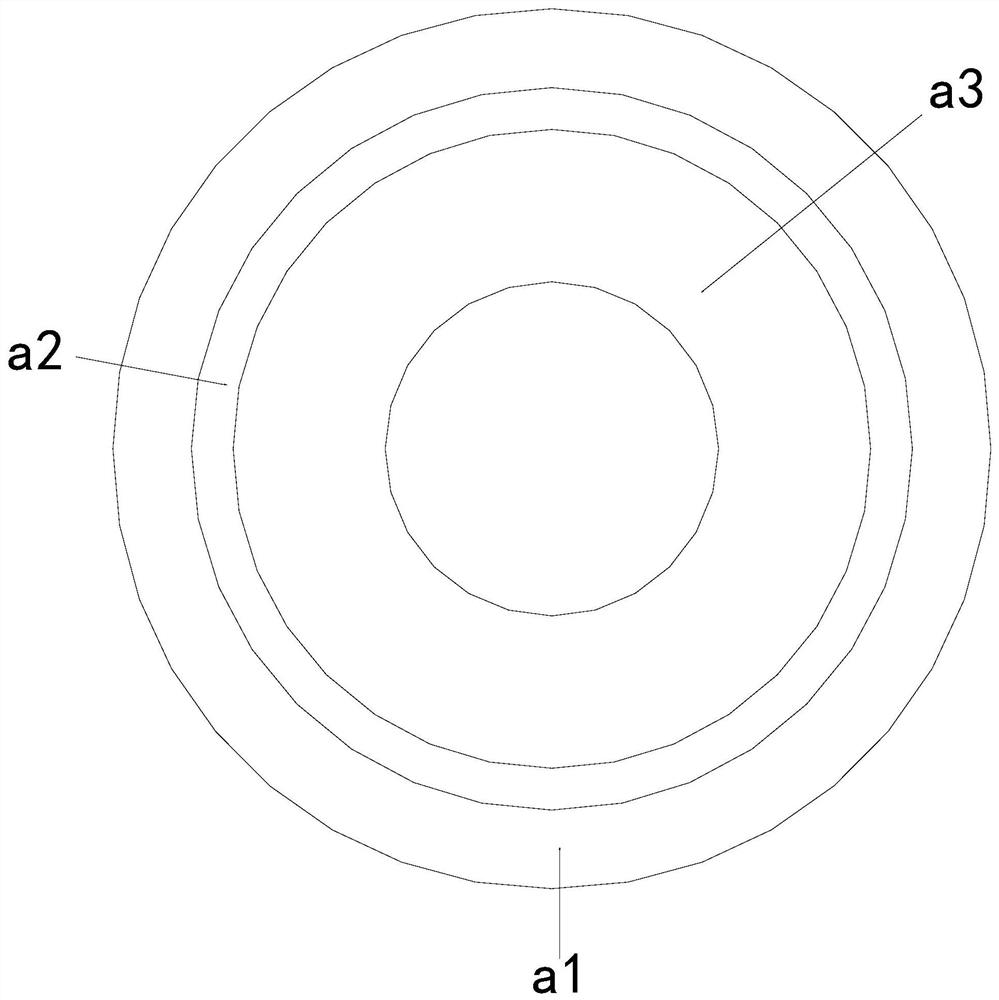

[0032] as attached Figure 4 As shown: the speed reducer a3 is composed of a friction device b1, a guide ring b2, a reducer b3, an embedded ring b4, and a ring body b5. One end of the friction device b1 is welded to the outer wall of the embedded ring b4, and the guide ring The outer wall of the ring b2 is nested and fitted on the inner wall of the friction device b1, the outer wall of one end of the reducer b3 is embedded and fixed inside the ring body b5, the outer wall of the embedded ring b4 is nested and fitted on the inner wall of the ring body b5, and the outer wall of the ring body b5 is embedded Fastened to the inner wall of the limit ring a2, there are three speed reducers b3, which are arranged circularly inside the ring body b5. The rotation speed when rotating is slowed down to a certain extent.

[0033] as attached Figure 5 To attach Figure 7 As shown: the friction device b1 is composed of an inlay device d1, a positioning ring d2, and an assembly seat d3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com