High-specific energy absorption lattice configuration under low-density condition

A low-density, dot-matrix technology, applied in the field of lightweight energy-absorbing structures, to avoid rapid decline in bearing capacity, improve bearing capacity, and stabilize platform loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

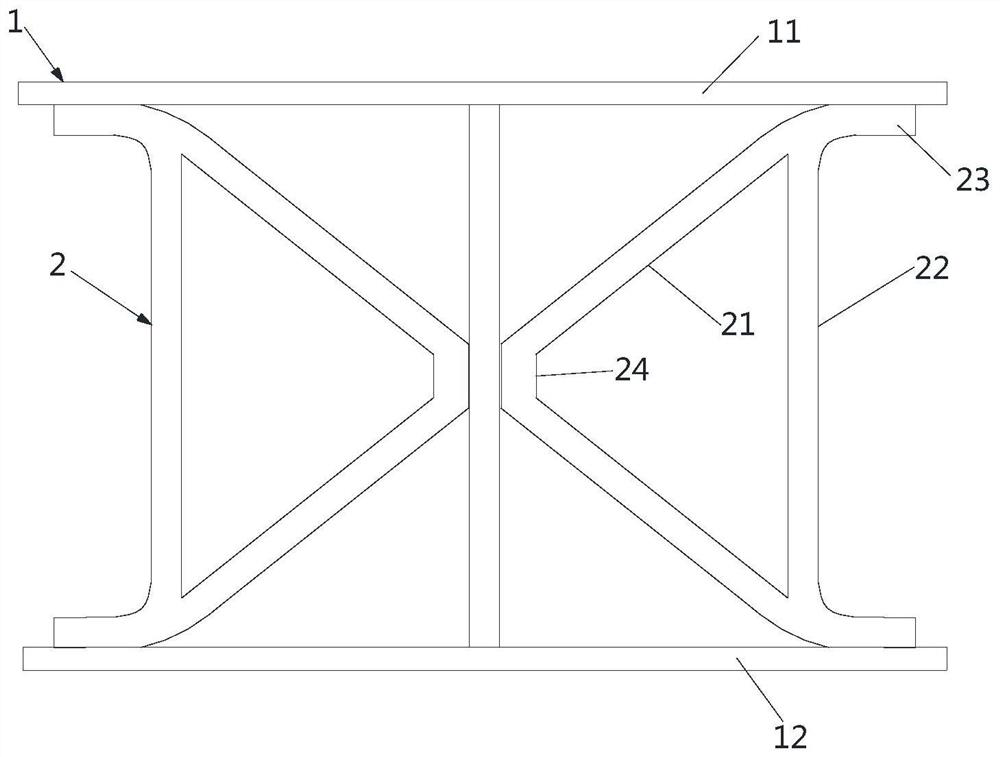

[0013] like figure 1 As shown, in one embodiment of the present invention, a high-specific energy-absorbing lattice configuration under low-density conditions is disclosed. The following description takes one of the lattices as an example to illustrate, and constitutes all points in the entire configuration. The array structures are consistent and independent of each other.

[0014] The specific lattice configuration includes the support plate 1 with upper and lower surfaces formed by the upper panel 11 and the lower panel 12 , and a lattice core material installed between the upper panel 11 and the lower panel 12 .

[0015] The support plate 1 is used as the inner surface and the outer surface of the lattice configuration, which can be flat or arc-shaped, and a plurality of mutually independent lattice core mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com