Sectional material scribing device and method for saw cutting center modification and saw cutting center modification method

A profile and sawing technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost, inability to have engraving and cutting at the same time, and not suitable for popularization and application, so as to save space and ensure beautiful appearance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

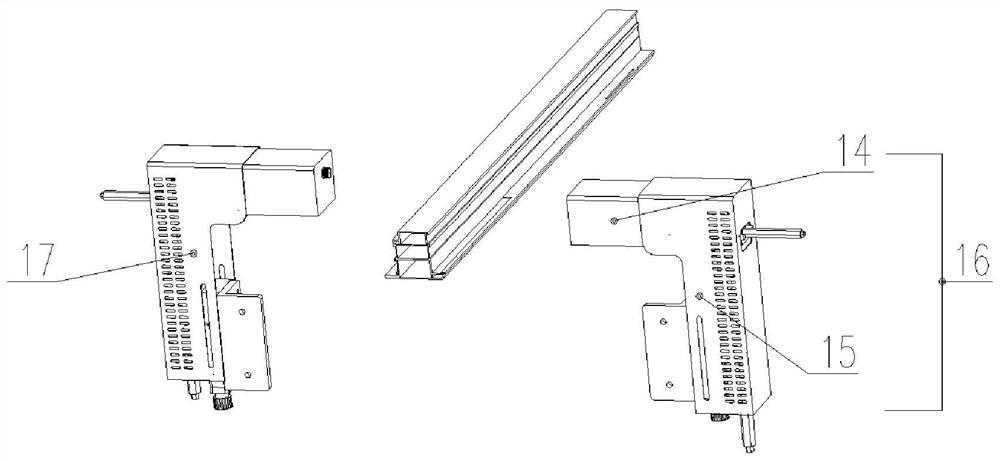

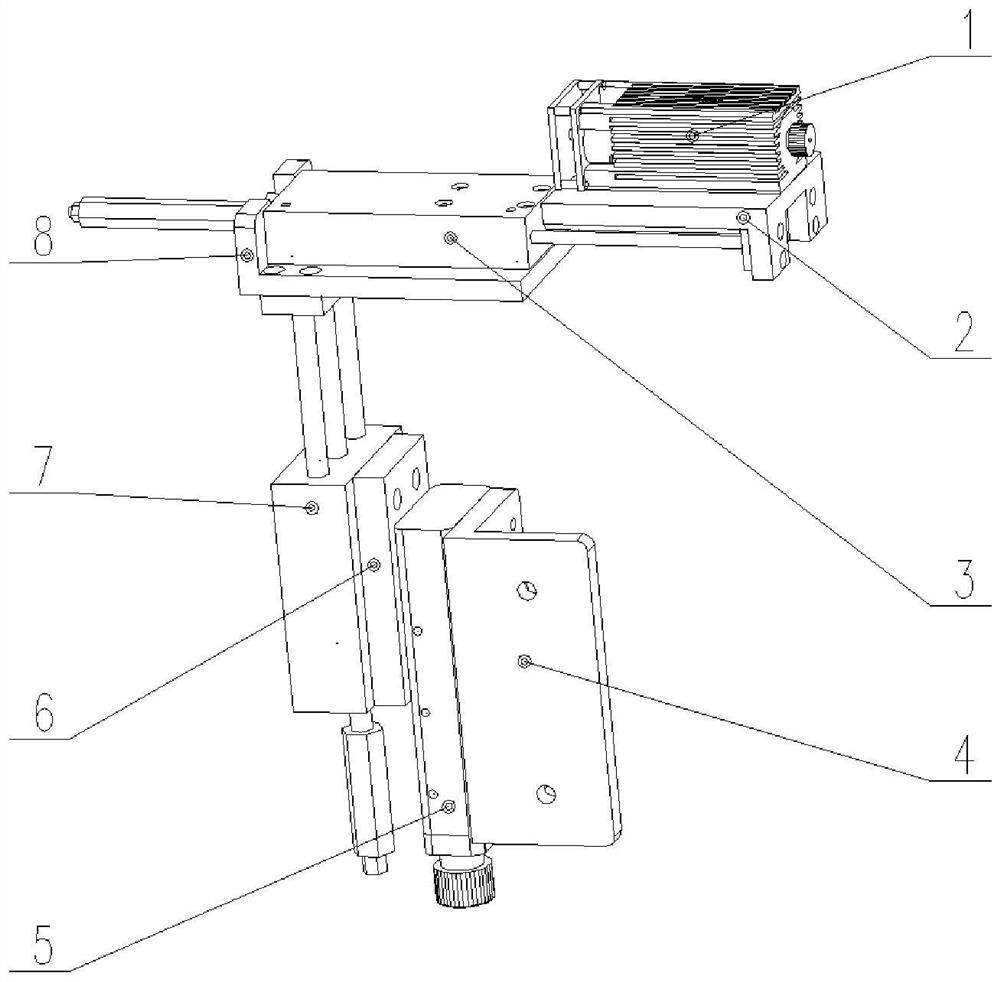

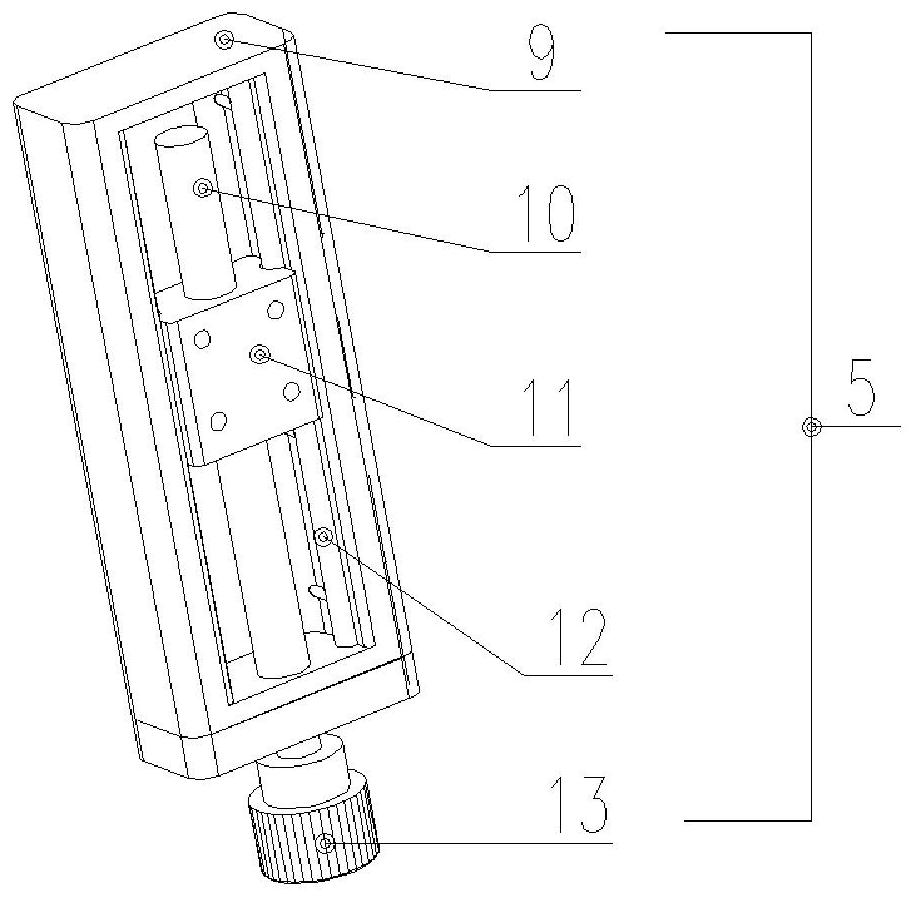

[0029] Such as Figure 1-3 As shown, the present invention is a first embodiment of a profile scoring device for refitting sawing centers, including a symmetrically arranged front scoring assembly 17 and a rear scoring assembly 16, the front scoring assembly 17 and the rear scoring assembly The scoring assembly 16 has the same structure; it also includes two fixed plates 4 and two vertical sliding mechanisms which are arranged symmetrically and have the same structure. Wherein, the fixing plate 4 is provided with a first installation part and a second installation part. Preferably, the shape of the fixing plate 4 is L-shaped, and the first installation part and the second installation part are respectively arranged on two planes perpendicular to each other. The fixed plate 4 is connected with the workbench at the front end of the sawing center feeding device through the first installation part, and a one-dimensional slide table 5 is installed on the second installation part o...

Embodiment 2

[0033] Such as Figure 4 As mentioned above, the second embodiment of the profile scoring device for refitting the sawing center of the present invention differs from the first embodiment in that, in this embodiment, only one fixing plate 4 and one vertical Straight slide mechanism, the vertical slide mechanism in the present embodiment comprises slide table connecting plate 18, and one side of described slide table connecting plate 18 is installed on the slider 11 of one-dimensional slide table 5, and described slide table connecting plate 18 The front and rear connecting frames 19 are installed on the other side of the front and rear connecting frames 19, and the horizontal connecting plates 8 of the front scoring line assembly 17 and the rear scoring line assembly 16 are all installed on the front and rear connecting frames 19.

[0034] Further, in this embodiment, the lower end of the lead screw 10 of the one-dimensional sliding table 5 is connected to the motor 20 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com