Catalyst for steam reforming of gasoline to produce hydrogen and preparation method thereof

A steam reforming and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of reducing catalyst activity, high carbon content in gasoline, Blocking the pores and other problems, to achieve the effect of improving catalytic activity, improving gasoline conversion rate, and strengthening interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

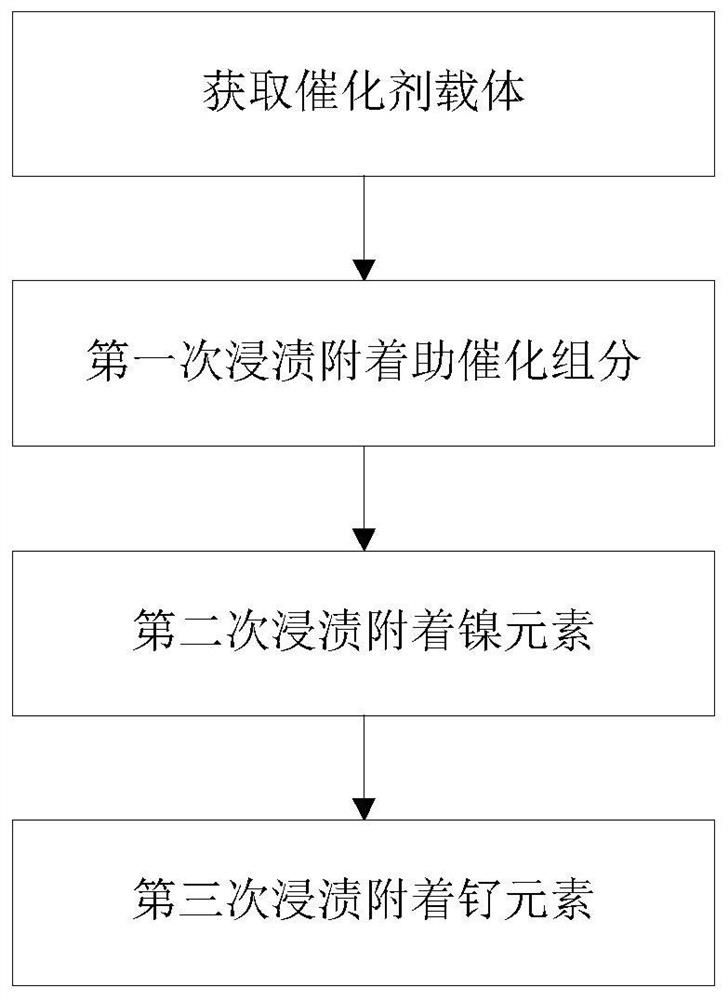

Method used

Image

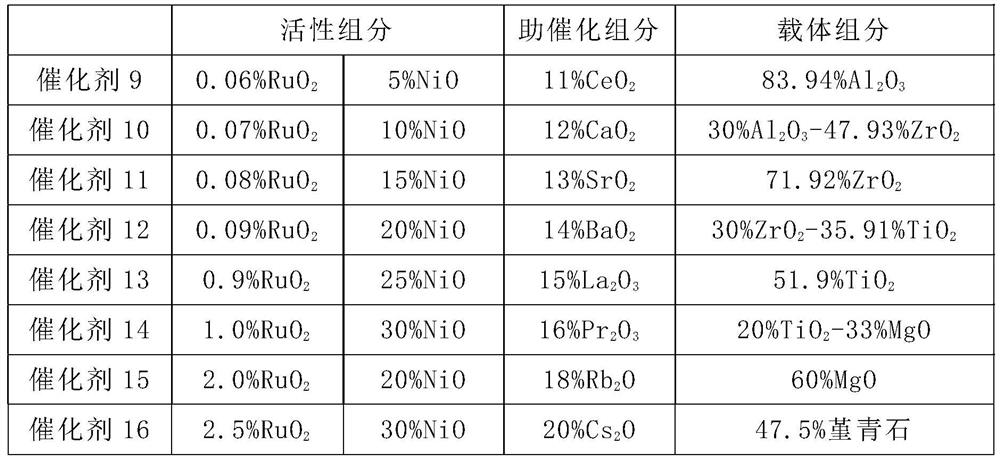

Examples

Embodiment 1

[0027] Gasoline steam reforming hydrogen production catalyst 1, including carrier component Al 2 o 3 , the active component NiO and the catalytic component CeO 2 ; Among them, Al 2 o 3 The mass proportion of NiO is 85%, the mass proportion of NiO is 10%, the mass proportion of CeO 2 5% by mass.

Embodiment 2

[0029] Gasoline steam reforming hydrogen production catalyst 2, including carrier component Al 2 o 3 , the active component NiO and the catalytic component CeO 2 ; Among them, Al 2 o 3 The mass proportion of NiO is 80%, the mass proportion of NiO is 10%, the mass proportion of CeO 2 10% by mass.

Embodiment 3

[0031] Gasoline steam reforming hydrogen production catalyst 3, including support component Al 2 o 3 , the active component NiO and the catalytic component CeO 2 ; Among them, Al 2 o 3 The mass proportion of NiO is 70%, the mass proportion of NiO is 10%, and the mass proportion of CeO 2 20% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com