System capable of obtaining clear phase of mixture and closestool

A mixture and phase-clearing technology, which is applied in mixers, sampling, sampling devices, etc., can solve the problems of reducing the service life of equipment, excessive noise, and increasing equipment loss, so as to reduce the number of replacements, simplify structural components, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

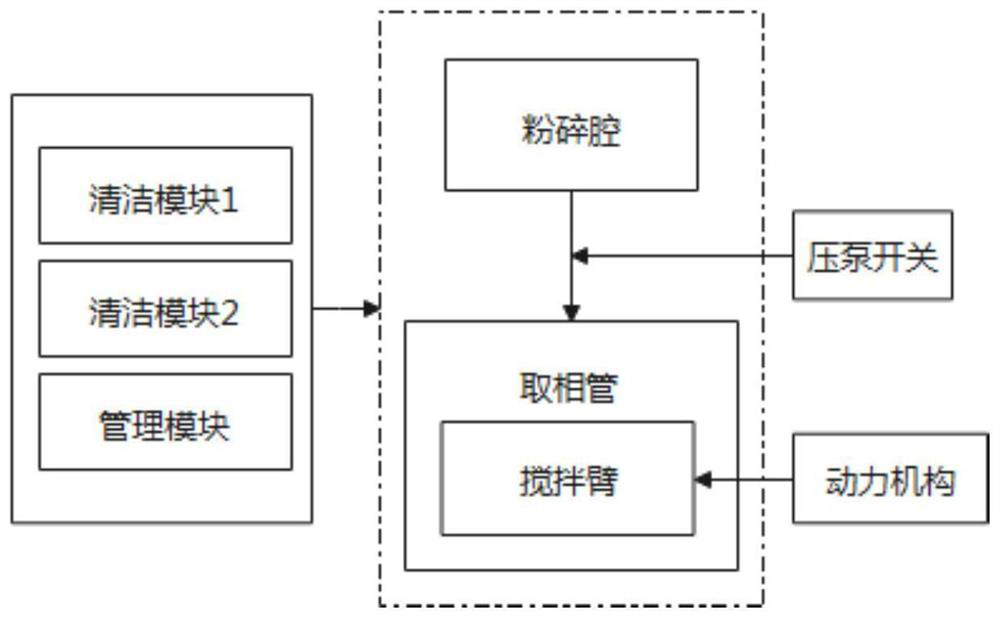

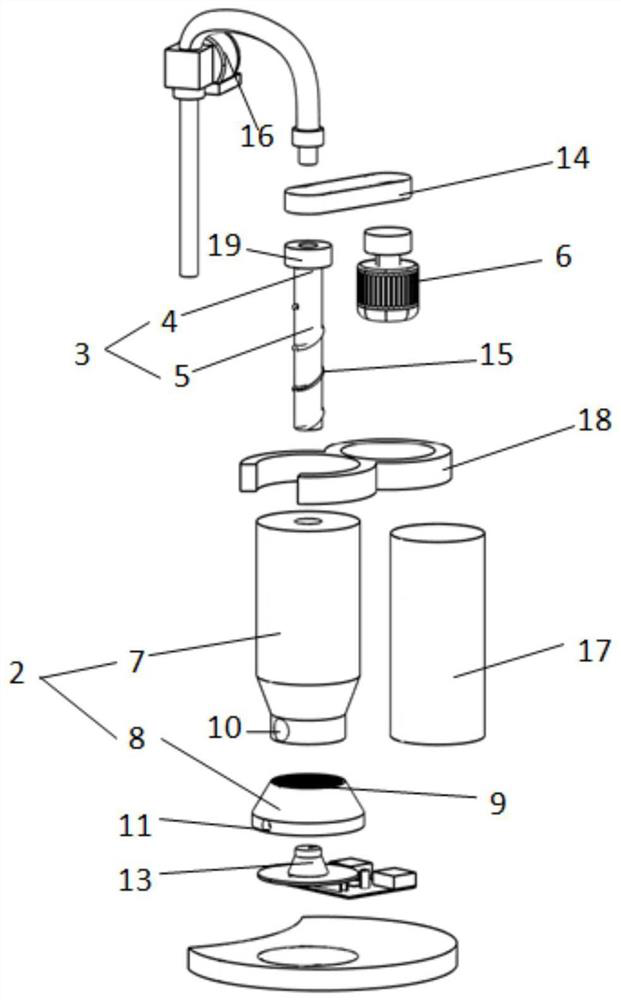

[0044] Embodiment 1 relates to a kind of system that can obtain the clear phase of mixture, as figure 1 , 2 , 4, 5, and 6 show:

[0045] The mixture is put into the aqueous solution for pulverization, and all operations are carried out in the pulverization chamber (1). After uniform mixing can be carried out by means of physical stirring or ultrasonic pulverization, the obtained turbid mixed solution is the first fluid. Pipelines are inserted in the pulverization chamber (1) for guiding the first fluid, wherein such as figure 2 As shown, the diversion first fluid can be sucked out of the crushing chamber (1), wherein the position of attracting the first fluid is as close as possible to the bottom of the crushing chamber (1), wherein the bottom of the crushing chamber (1) can be designed to be inclined, and on the inclined side Set up a waste port for liquids. The first fluid that does not need to be separated is led out of the crushing chamber (1) through the waste liquid ...

Embodiment 2

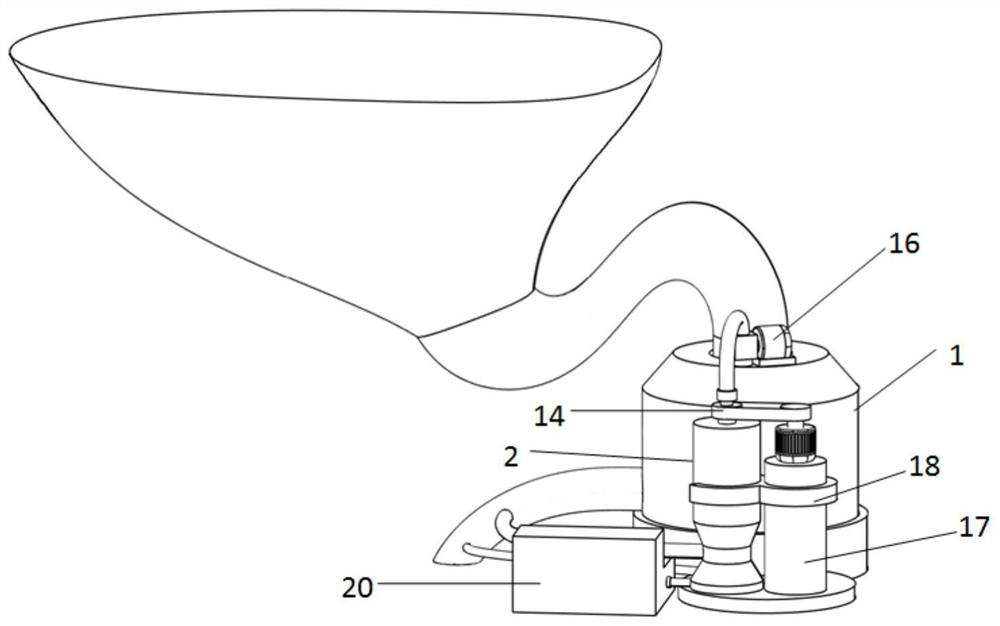

[0053] Embodiment 2 relates to a kind of toilet that can obtain mixture phase such as Figure 2-6 Shown:

[0054] This toilet has the design of one or more software or hardware systems in embodiment 1, wherein, carry out adjacency and place side by side for taking phase tube (2) and power mechanism, set support structure (17) below the power mechanism for Fix the power mechanism, electronic devices, resistors, power supplies, etc. can be set in the support structure (17) to be used to control the rotating motor (6), wherein the support structure (16) can be cylindrical, or other shapes, any for the support structure (16) ) changes in shape all belong to the scope of protection of the present invention, and the transverse section of the inner wall of the phase-taking tube (2) is all circular, which is convenient for cleaning, and the shape of the outer wall can be freely set according to the external space to help fix the phase-taking tube (2) ; Wherein, the support structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com