Making method of low-GI coarse cereal noodles

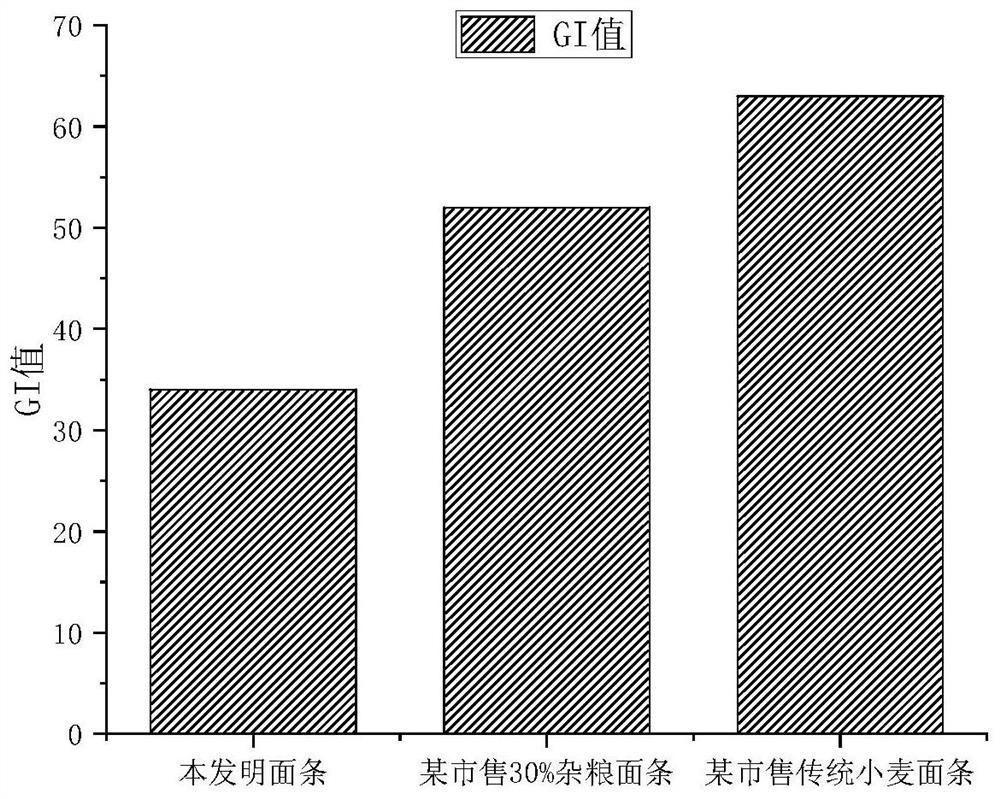

A kind of miscellaneous grain noodles and the technology of the production method are applied to the functions of food ingredients, food ingredients as a gelling agent, food heat treatment, etc., which can solve the problems of unfavorable consumption by obese and diabetic people, difficult noodles, low cooking loss rate, etc., and achieve Reduced digestive properties and glycemic index, low cooking loss rate, and rich nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

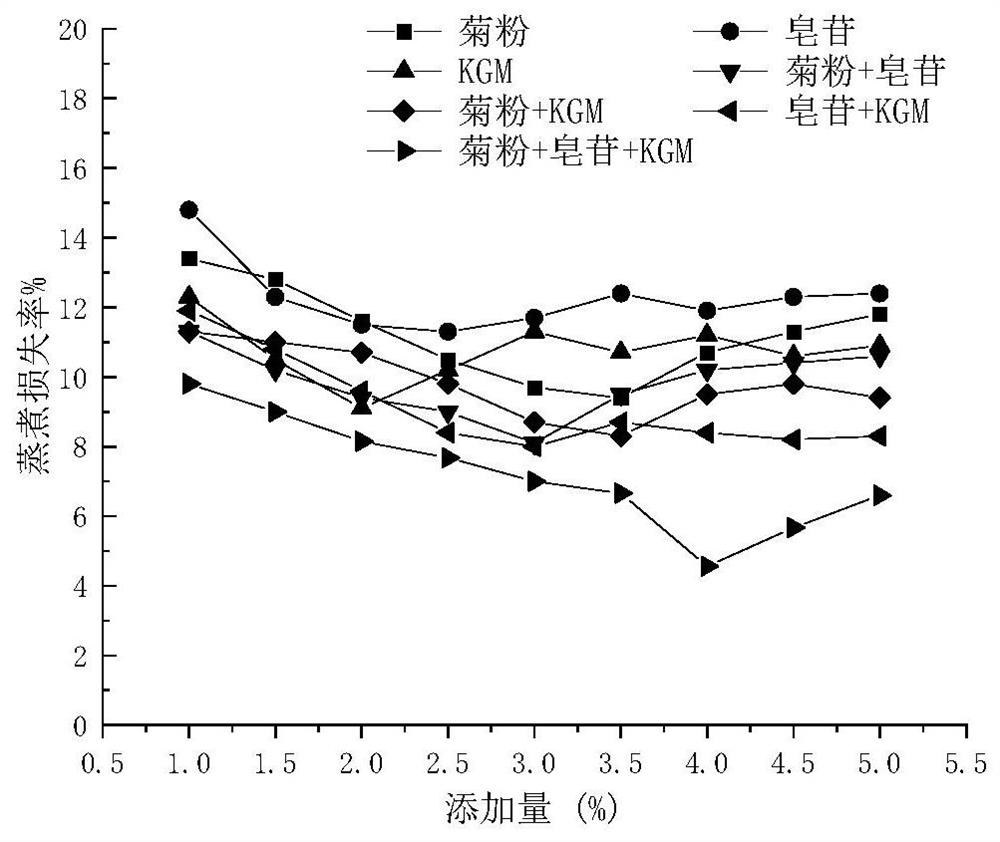

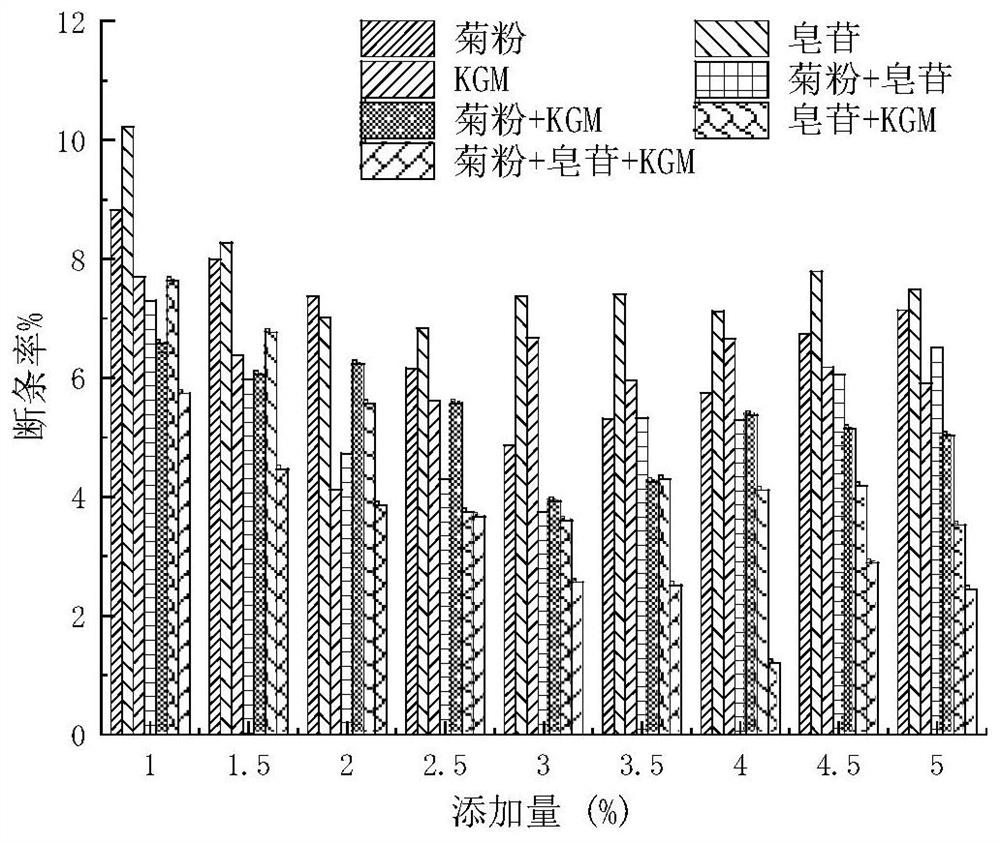

Embodiment 1

[0046]A method for making low GI miscellaneous grain noodles, comprising the steps of: using the raw materials of quinoa, buckwheat, oats and highland barley (in terms of raw material 100kg), the mass ratio of quinoa, buckwheat, oats and highland barley is 5:2:1: 1; Mix the raw materials and crush them until they pass through a 80-mesh sieve. The pulverized raw materials were subjected to microwave pregelatinization treatment, the microwave power was 300W, and the treatment time was 3.5min. Based on the quality of raw materials, 5% quality improver and 3% salt must be added before pregelatinization. The improver includes whey protein, ovalbumin, inulin, saponin and KGM, and the mass ratio is 30:25:18 :15:12. After pre-gelatinization, add water to the powder (the amount of water added is 40% of the raw material mass) for vacuum kneading, the kneading vacuum degree is 0.05 MPa, and the kneading time is 13 minutes; the dough is taken out of the kneading machine, and the dough is...

Embodiment 2

[0048] A method for making low GI miscellaneous grain noodles, comprising the steps of: using the raw materials of quinoa, buckwheat, oats and highland barley (in terms of raw material 100kg), the mass ratio of quinoa, buckwheat, oats and highland barley is 5:1:1: 1. Mix the raw materials and pulverize them until they pass through an 80-mesh sieve; conduct microwave pregelatinization treatment on the pulverized raw materials with a microwave power of 300W and a treatment time of 4 minutes. Based on the quality of raw materials, 6% quality improver and 3% salt must be added before pregelatinization. The improver includes whey protein, ovalbumin, inulin, saponin and KGM, and the mass ratio is 30:25:18 :15:12. After pre-gelatinization, add water to the powder (the amount of water added is 41%) for vacuum kneading, the kneading vacuum degree is 0.05MPa, and the kneading time is 13 minutes; the dough is taken out from the kneading machine, and the dough is rested for 45 minutes; P...

Embodiment 3

[0050] A method for making low GI miscellaneous grain noodles, comprising the steps of: using the raw materials of quinoa, buckwheat, oats and highland barley (in terms of raw material 100kg), the mass ratio of quinoa, buckwheat, oats and highland barley is 6:1:1: 1. Mix the raw materials and pulverize them until they pass through an 80-mesh sieve; conduct microwave pregelatinization treatment on the pulverized raw materials with a microwave power of 300W and a processing time of 5 minutes. Based on the quality of raw materials, 6% quality improver and 3% salt must be added before pregelatinization. The improver includes whey protein, ovalbumin, inulin, saponin and KGM, and the mass ratio is 30:25:18 :15:12. After pre-gelatinization, add water to the powder (the amount of water added is 41%) for vacuum kneading, the kneading vacuum degree is 0.05MPa, and the kneading time is 13 minutes; the dough is taken out from the kneading machine and rested for 45 minutes; Put the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com