High-protein and high-calcium milk and preparation method thereof

A high-protein, high-calcium technology, applied in the field of high-protein, high-calcium milk preparation, can solve the problems of strong powder texture, affecting product taste and flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

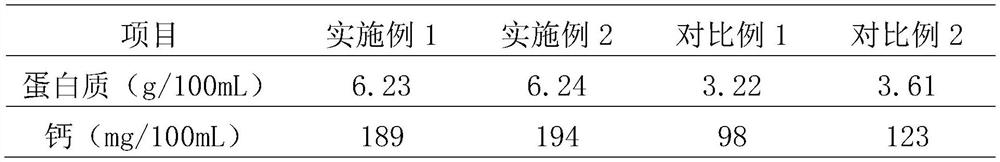

Embodiment 1

[0036] The present embodiment provides a high-protein, high-calcium milk, which has the following raw material composition (based on 1000 parts by weight of semi-finished products):

[0037] Raw milk 1800-2000 parts by weight

[0038] Raw material standard:

[0039] Raw milk: in line with GB19301-2010 standard.

[0040] The high-protein, high-calcium milk provided in this example is prepared by the following steps:

[0041] (1) Partial fat separation of raw milk: use a 30-mesh double filter to filter and remove impurities from ordinary raw milk, then preheat to 50°C, and use a separator to separate the fat part to obtain a partial skim milk with a fat content of 2.0%. ;

[0042] (2) Pasteurization: Pasteurize part of the skimmed milk at a temperature of 65°C for 50 seconds;

[0043] (3) ultrafiltration concentration: carry out ultrafiltration concentration to the partially skimmed milk after pasteurization, and the concentration ratio is 1.3 times to obtain the concentrate...

Embodiment 2

[0047] The present embodiment provides a high-protein, high-calcium milk, which has the following raw material composition (based on 1000 parts by weight of semi-finished products):

[0048] Raw milk 1800-2000 parts by weight

[0049] Raw material standard:

[0050] Raw milk: in line with GB19301-2010 standard.

[0051] The high-protein, high-calcium milk provided in this example is prepared by the following steps:

[0052] (1) Partial fat separation of raw milk: use a 30-mesh double filter to filter and remove impurities from ordinary raw milk, then preheat to 50 ° C, and use a separator to separate the fat part to obtain a partial skim milk with a fat content of 2.0%. ;

[0053] (2) Pasteurization: Pasteurize part of the skimmed milk at a temperature of 65°C for 50 seconds;

[0054] (3) ultrafiltration concentration: carry out ultrafiltration concentration to the partially skimmed milk after pasteurization, the concentration ratio is 1.6 times, and obtains the concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com