Steady-flow feeder

A feeder and steady flow technology, applied in the direction of conveyors, conveyor objects, conveying bulk materials, etc., can solve the problems of flushing or material breakage fluctuations, and achieve the effect of solving the problem of flushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

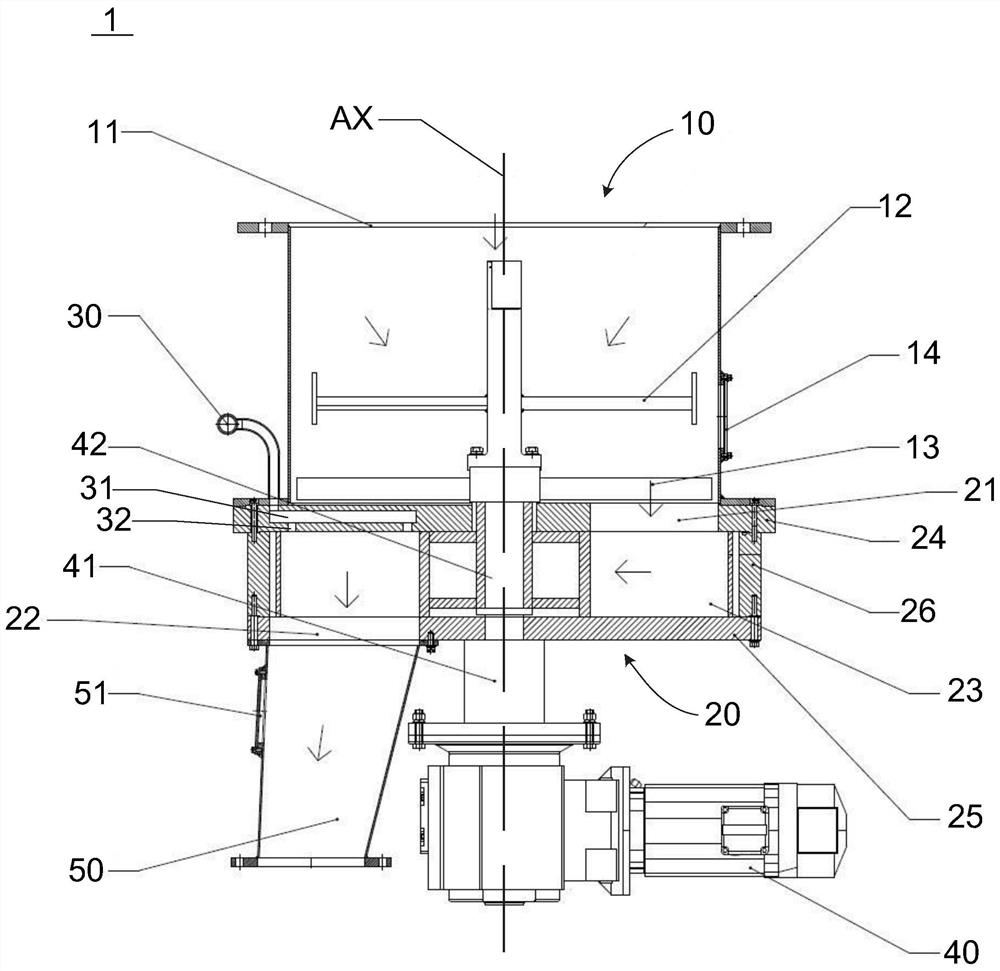

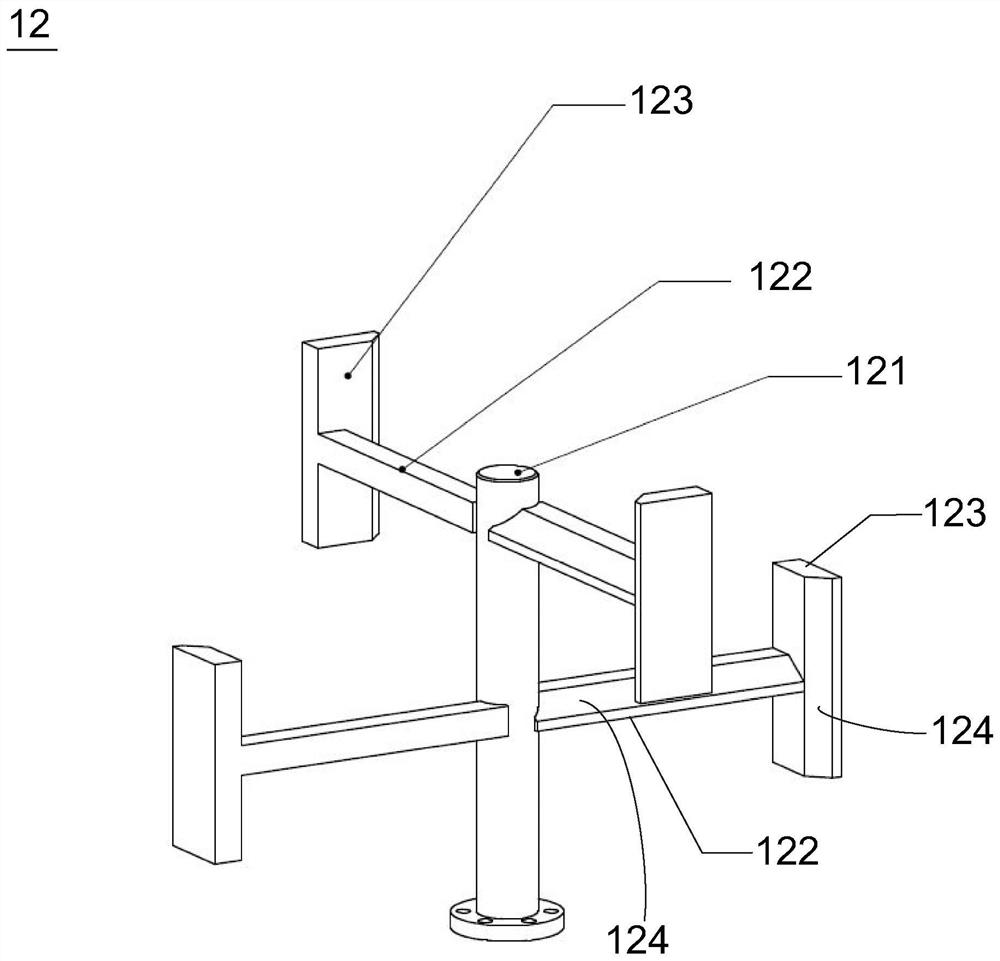

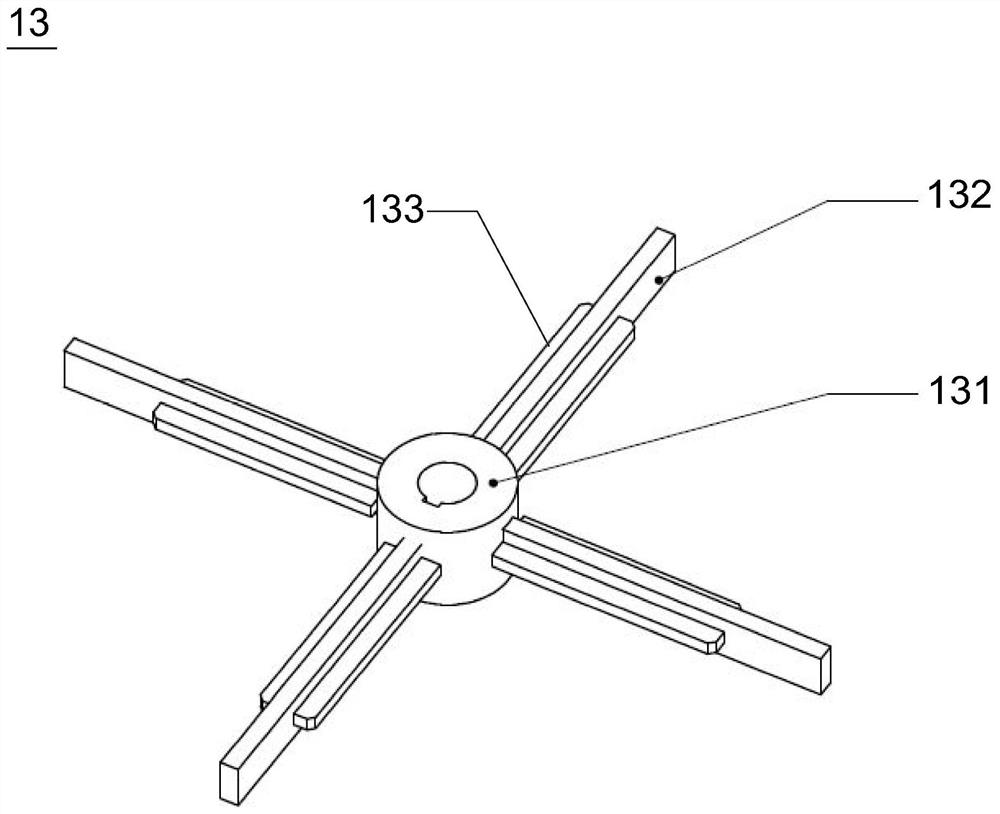

[0062]Referring now to the accompanying drawings, specific embodiments of the present invention will be described in detail. What is described here is only a preferred embodiment of the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention.

[0063] The invention provides a steady flow feeder for conveying powder. For example, the steady flow feeder can be used in the process of feeding and batching coal powder, raw meal powder, mineral powder, fly ash, kiln dust and other powder materials in the cement production process, and solves the problem of material interruption during powder conveying Or the problem of feeding fluctuations such as punching. Introduce in detail below in conjunction with accompanying drawing.

[0064] Such as figure 1 As shown, the steady flow feeder 1 according to the first embodiment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com