3D printing machine automatic material adding networking feedback device and working method thereof

A 3D printer and feedback device technology, applied in the field of 3D printing, can solve problems such as hindering printing, damaging printed objects, and waste of printed materials, so as to achieve the effect of solving material breakage and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

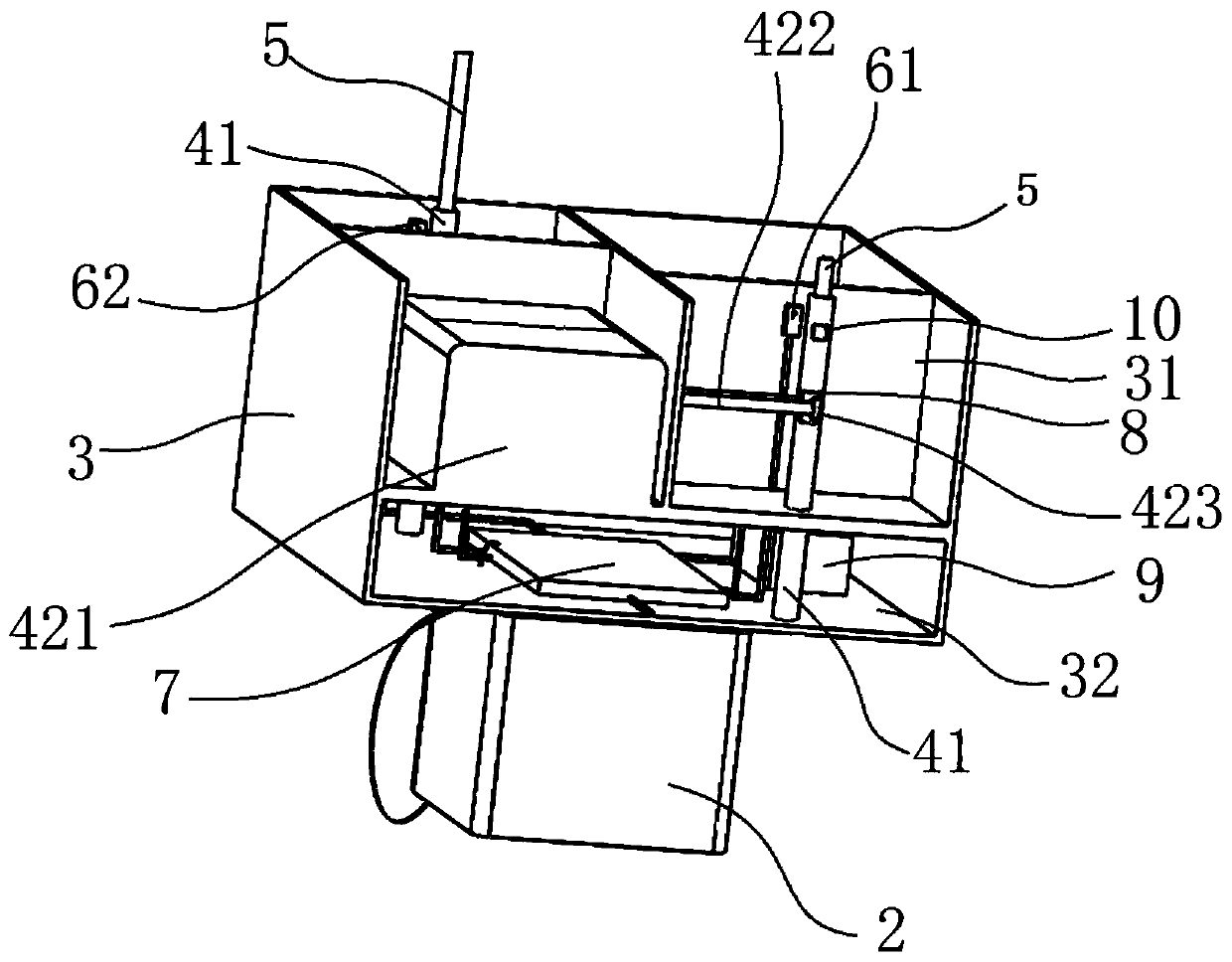

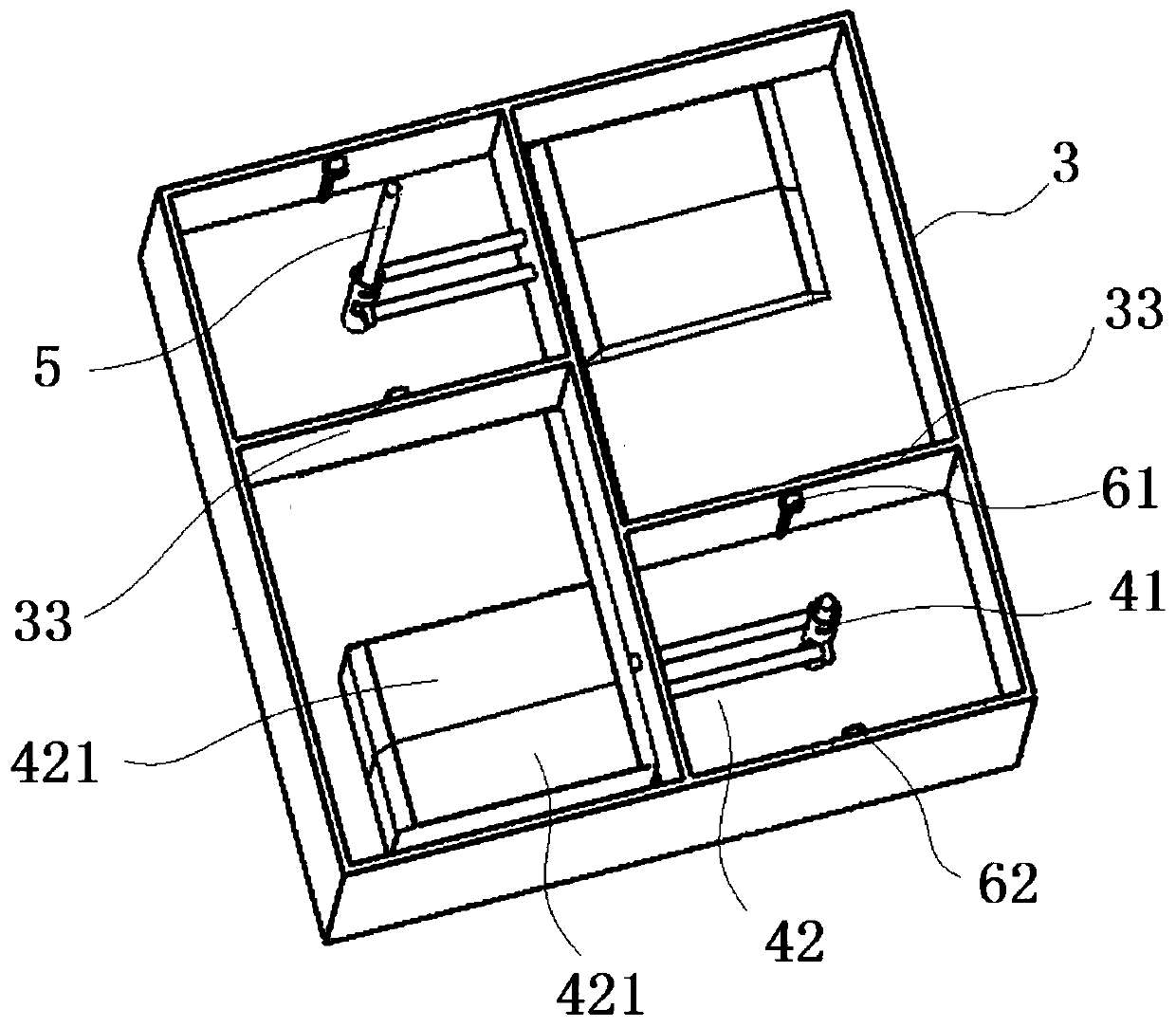

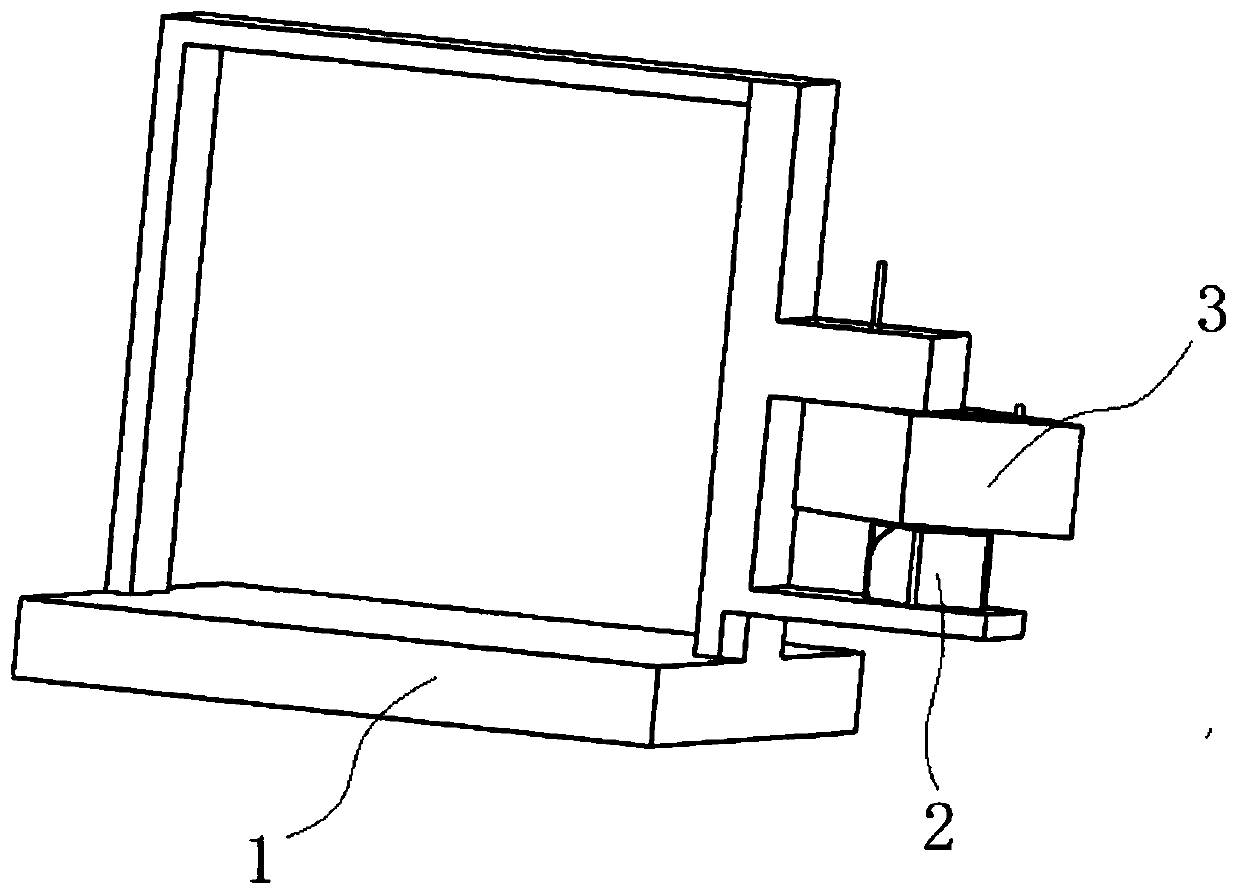

[0037] Figure 1 to Figure 7It is the first embodiment of a 3D printer automatic material feeding network feedback device of the present invention, which includes a frame 1, a rotating motor 2 mounted on the frame 1, and a feed box 3 installed on the output shaft of the rotating motor 2. Two groups of feeding devices 4 are arranged on the material box 3, and detection devices for detecting materials 5 are arranged on the two groups of feeding devices 4, and the rotating motor 2, the feeding device 4 and the detection devices are all respectively connected to a networked control center 7 And power supply unit 9. In the 3D printing process, at first one group of feeding devices 4 provides materials 5 to the 3D printer. Send a signal; after the network control center 7 receives the signal, it sends a corresponding instruction to the rotating motor 2 and another group of feeding devices 4; after the rotating motor 2 receives the instruction, it drives the feeding box 3 to rotate,...

Embodiment 2

[0049] A working method of a 3D printer automatic feed feeding network feedback device, comprising the following steps:

[0050] S1: Load the material 5 into the feed port 411 of the material guide channel 41 in the two sets of feed devices 4 respectively, and make the material 5 be clamped between the two sets of rollers 423;

[0051] S2: start the 3D printer, make one of the feeding devices 4 work;

[0052] S3: The two groups of roller motors 421 of this group of feeding device 4 respectively drive two rollers 422 to rotate, and the rollers 422 respectively drive the rollers 423 connected to them to rotate, thereby driving the two groups of rollers 423 clamped between and located at The material 5 in the material guide channel 41 is passed vertically upwards, and is transported to the feed port of the 3D printer through the discharge port 412 of the material guide channel 41;

[0053] S4: when the end of the material 5 is about to leave the position of the detection window ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com