Dry-method powder preparation device and method adopting roll press for powder grinding

A technology of dry powder milling and roller compaction machine, applied in the direction of granulating raw materials, supply devices, separation methods, etc., can solve the problem of whether the dry powder milling pellets should be stale without clarifying from the principle, and it is difficult to use high-grade and low-cost The production of floor tiles with absorption rate and insufficient abrasiveness of raw materials for dry pulverizing can achieve the effects of improving homogenization effect and efficiency, reducing floor space and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

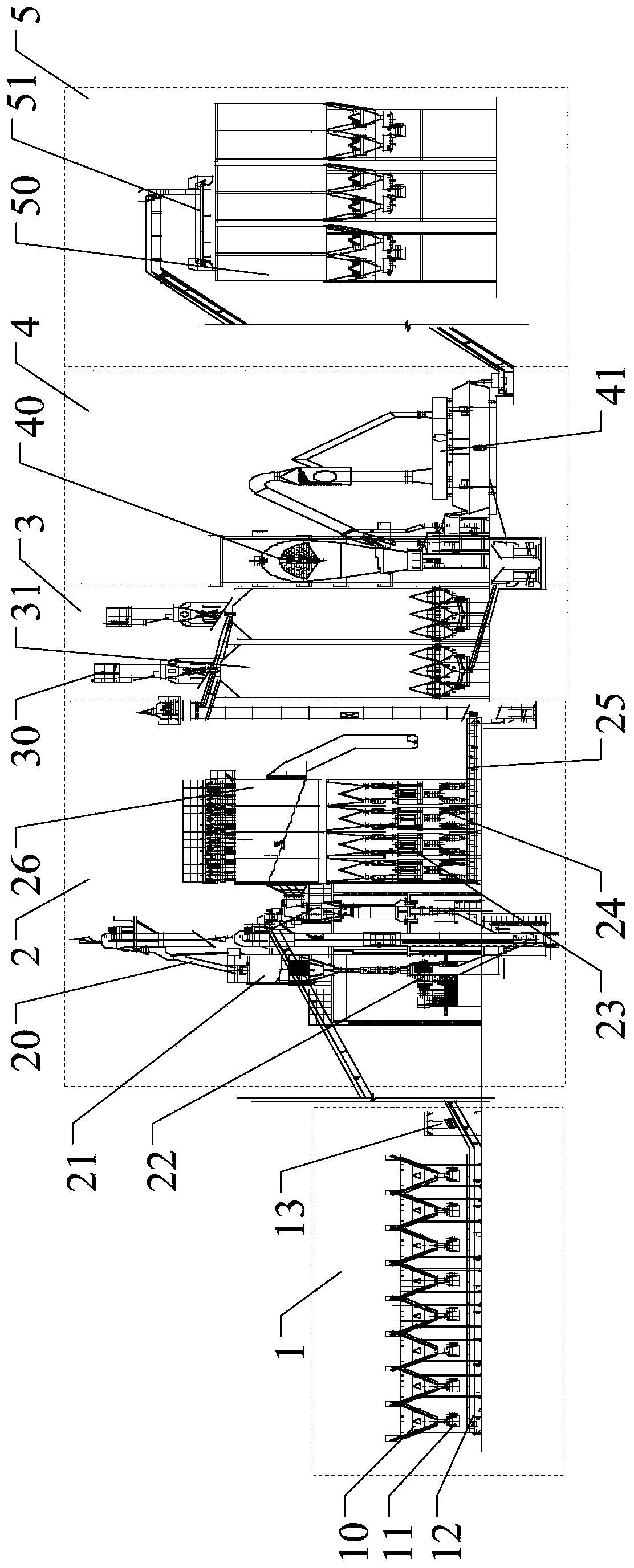

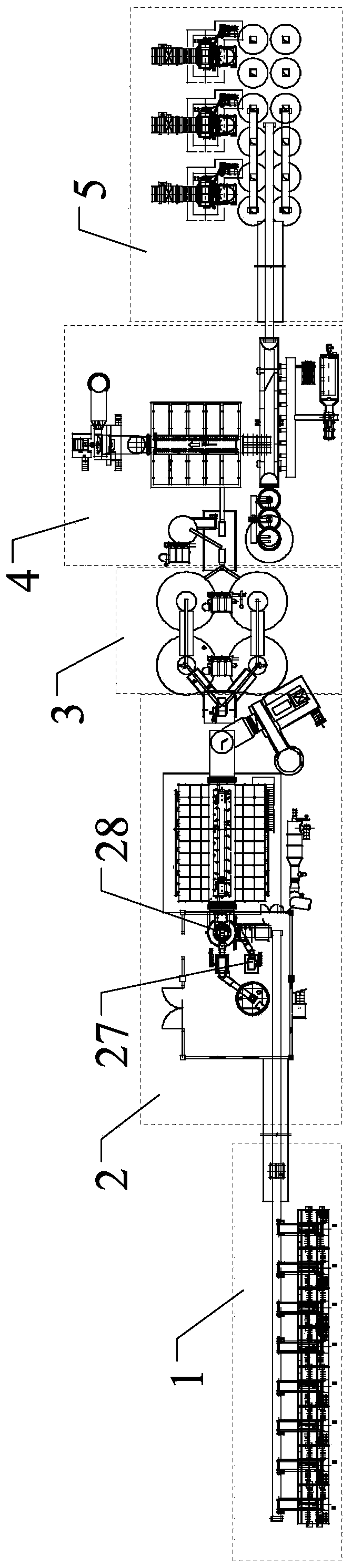

[0061] figure 1 It is a front view of a dry powder milling device using a roller press mill according to an embodiment of the present invention; figure 2 It is a top view of a dry powder milling device using a roller press mill according to an embodiment of the present invention, as shown in figure 1 with figure 2 As shown, the structure of the present invention includes a feeding unit, a grinding impurity removal unit, a dry powder homogenization storage unit, a granulation drying unit and a press feeding unit arranged sequentially along the production line, and the grinding and impurity removal unit includes the same The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com