Wafer glass powder wiping device

A technology of glass powder and wafer, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems that the thickness of glass powder is difficult to ensure uniformity, the quality of wiping is difficult to be guaranteed, and the pass rate of chip production is affected. Uniformity, convenient control and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

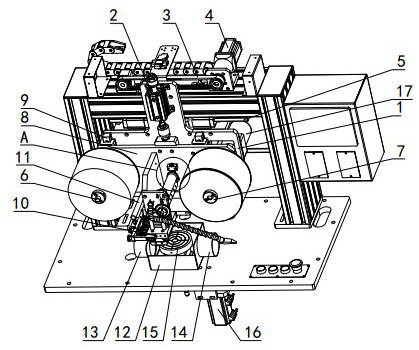

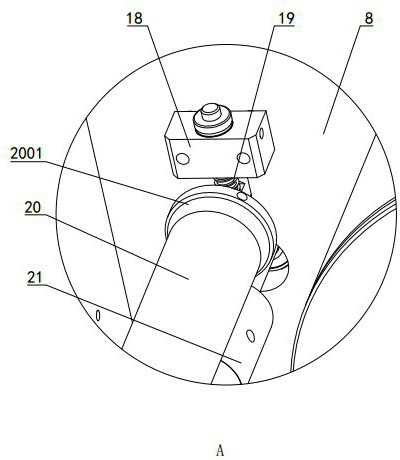

[0025] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0026] A wafer glass powder rubbing device, including a pressurizing device, a reciprocating device and a tray 15, the pressurizing device is installed on the reciprocating device, and reciprocates with it, the bottom of the pressurizing device is provided with a pressing part, and the tray 15 is arranged directly under the pressing part, and the tray 15 is provided with an adsorption part for fixing the wafer. The pressing device of the wafer glass powder rubbing device presses the wafer through the pressing part, and the kraft paper is placed on the pressing part, and the reciprocating motion device drives the pressing device to reciprocate, so that the pressing part and the wafer realize relative movement, To wipe the glass powder on the wafer, the adsorption part on the tray 15 can absorb the wafer firmly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com