Method for triggering solenoid valve and evaluation and control unit

A solenoid valve and electromagnetic damping technology, applied in the direction of electromagnets, electrical components, engine components, etc., can solve the problems of switching noise valve seat or valve closing component wear, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

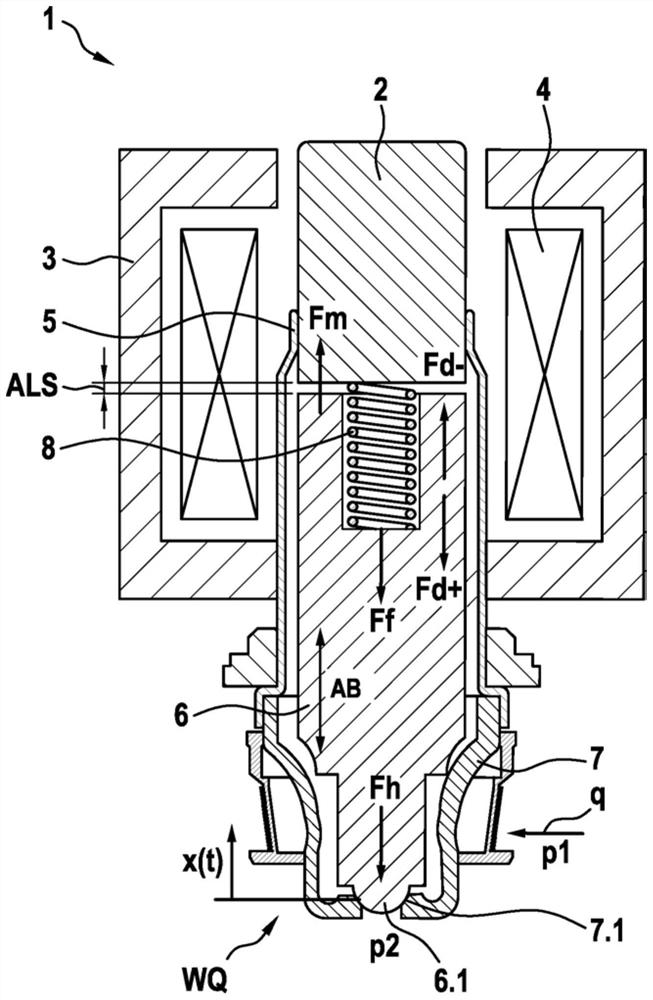

[0032] as by figure 1 It can be seen that the shown embodiment of the solenoid valve 1 comprises a magnet assembly 3 with an electric coil 4 and a movably supported magnet armature 6 with a closing element 6.1 which is activated by the magnet assembly 3 to overcome the return spring The force of 8 moves along the direction of motion. In the closed state of the solenoid valve 1 shown, the closing element 6.1 bears sealingly against the valve seat 7.1. In the open state of the solenoid valve 1 , not shown, the closing element 6 . 1 lifts off the valve seat 1 and sets the effective opening cross section WQ of the solenoid valve 1 .

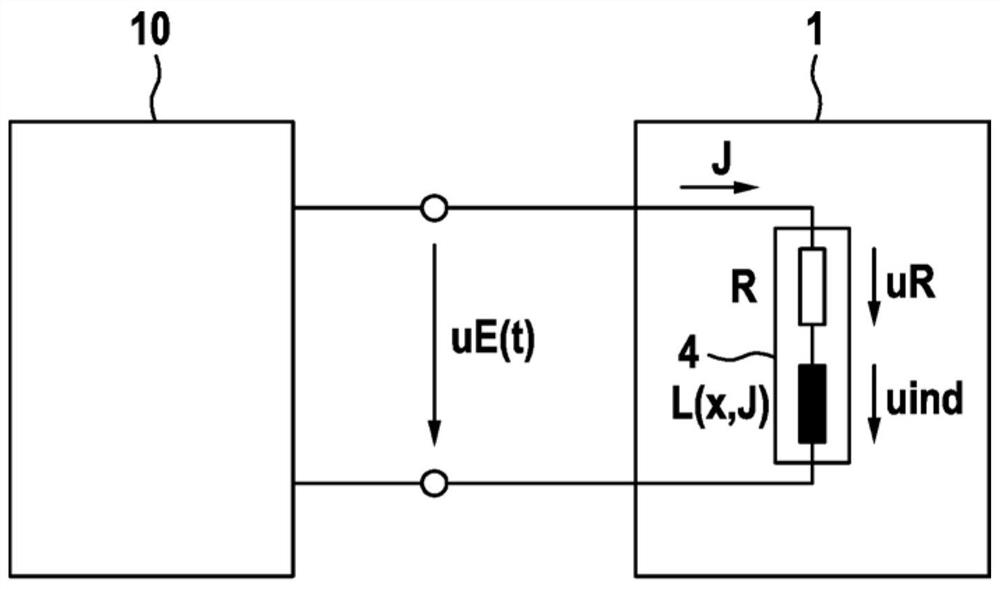

[0033] From figure 1 It can also be seen that the solenoid valve 1 shown corresponds to a normally closed 2 / 2 solenoid valve with the ball and cone seat in the closed armature position. From figure 2 It can also be seen that a voltage uE acts on the magnet assembly 3 , so that a coil current J flows in the electric coil 4 , whereby a magnetic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com