Special furnace core for new energy biological methyl ester fuel

A technology of biomethyl ester and new energy, which is applied in the direction of burners, lighting and heating equipment, etc. It can solve the problems that the air volume is difficult to ensure accurately and the unfavorable fuel is fully burned, so as to achieve the effect of ensuring sufficient combustion and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

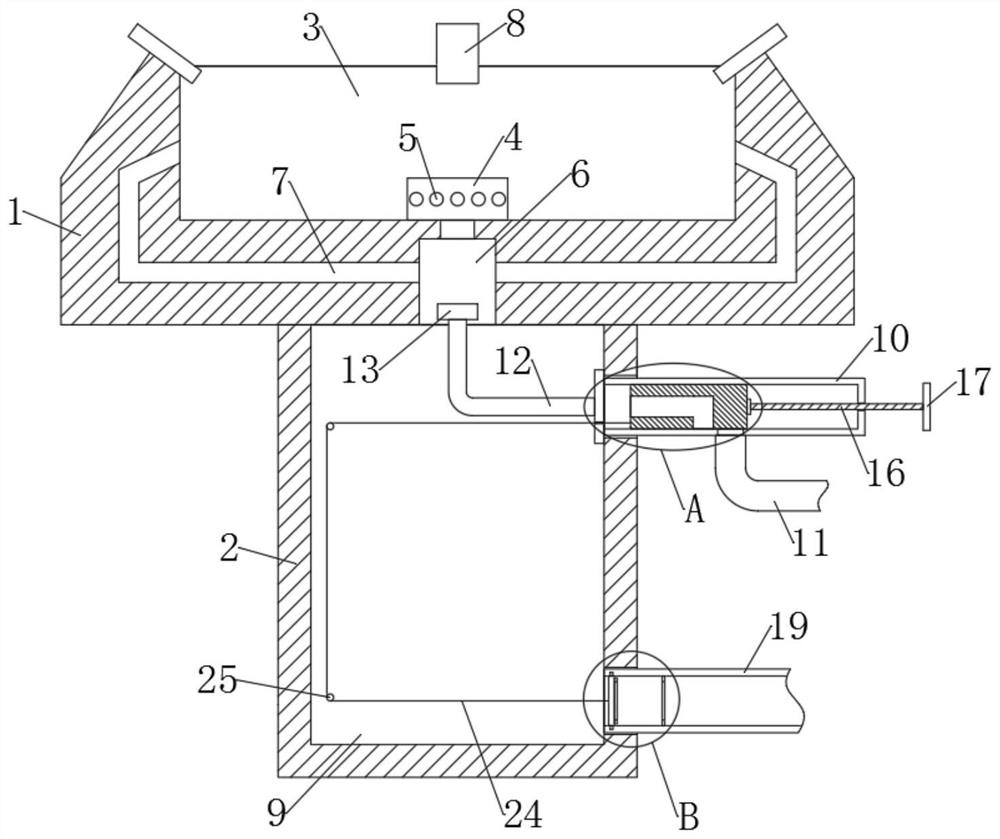

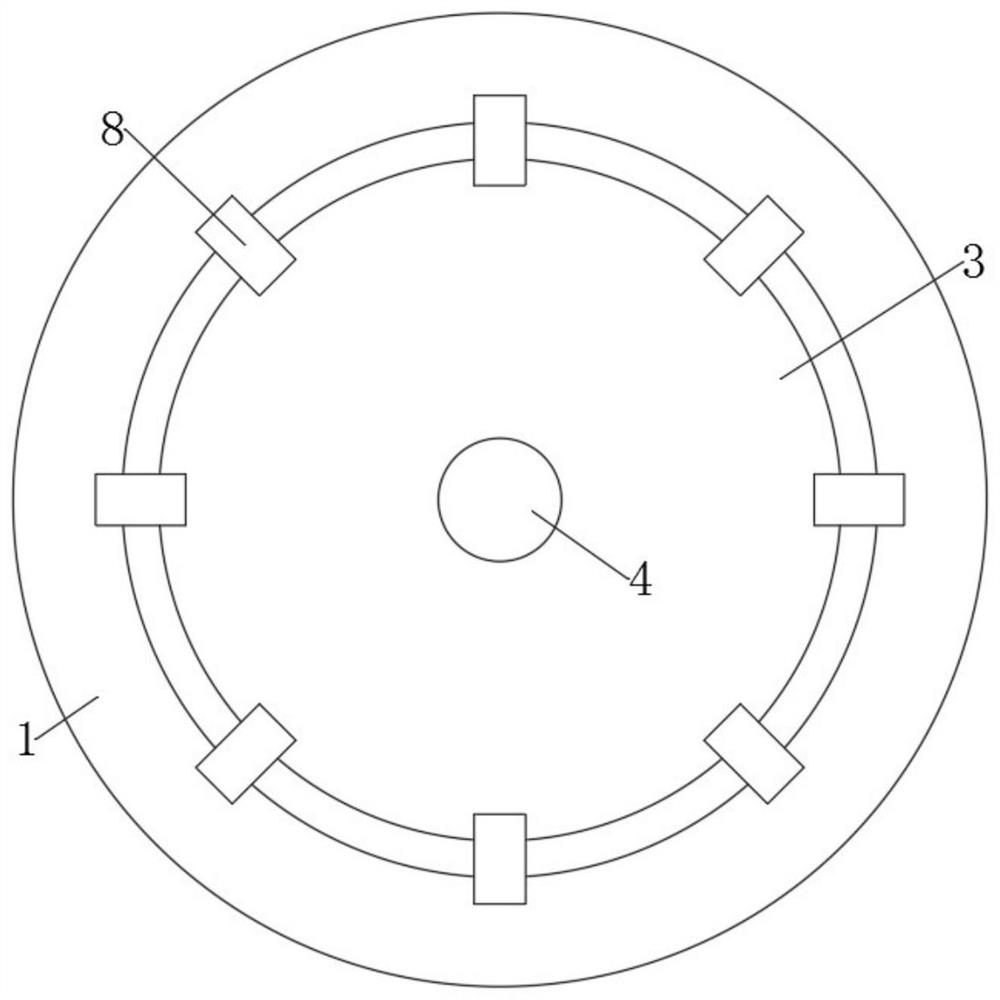

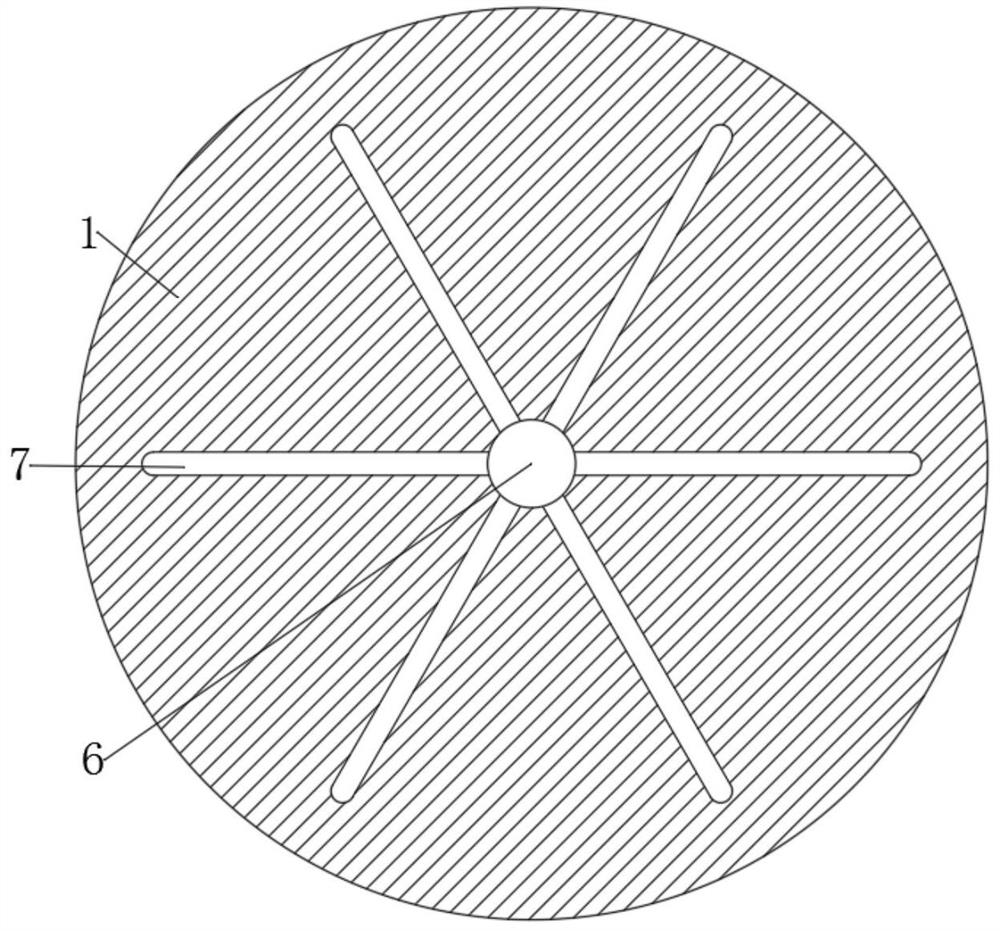

[0024]ReferFigure 1-6, A dedicated fuel of a new energy biological methyl ester fuel, including the head 1 and the furnace seat 2, the furnace head 1 fixedly connected to the upper side wall of the housing 2, the inside of the furnace 2 is provided with an air chamber 9, a furnace The upper side wall of the head 1 is opened, and the burn chamber 3 is fixed to the side wall of the combustion chamber 3, and there is a cavity in the inside of the nozzle 4, and there is a cavity, and there is a plurality of discharge holes 5, furnace. The lower end side wall of the head 1 is opened having a fuel injection chamber 6, and the side walls of the furnace head 1 are connected to the plurality of ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com