Polymer-containing produced liquid demulsifier and preparation method thereof

A demulsifier and production fluid technology, which is applied in the field of polymer-containing production fluid demulsifiers and its preparation, can solve the problems of reduced coalescence ability of emulsified oil droplets, increased difficulty in demulsification of polymer-containing production fluid, and serious oil-water emulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

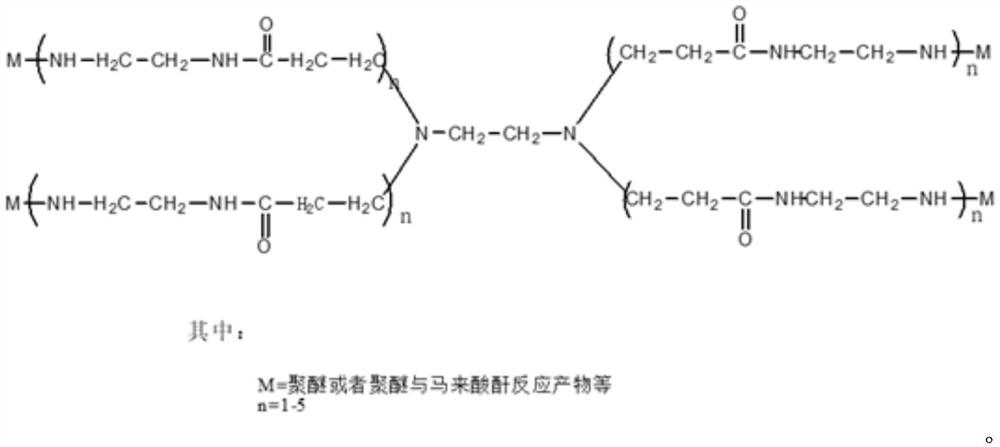

Method used

Image

Examples

Embodiment 1

[0021] Add 30g of pentaerythritol as the initiator in the closed high-pressure reactor, add 0.6g of sodium hydroxide, and keep the reaction temperature at 120°C under stirring after the reactor is repeatedly replaced with nitrogen. Keeping the reaction time for 1 h, after natural cooling, a PO / EO / PO tri-block polyether polyol was obtained, which was used as a blank control example as a demulsifier.

Embodiment 2~4

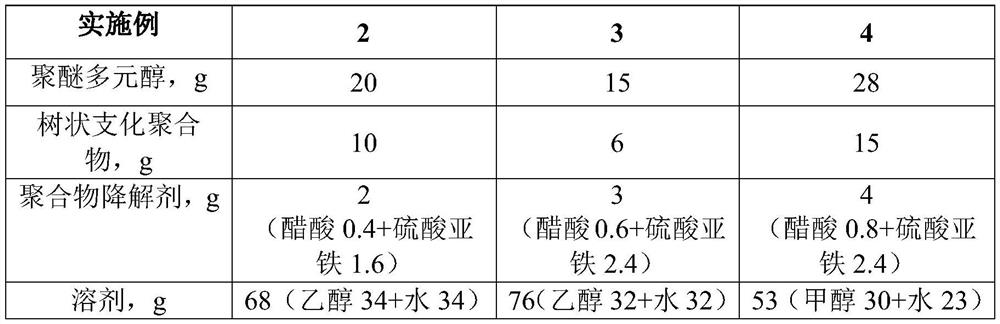

[0023] According to the ratio listed in Table 1, the polyether polyol obtained in Example 1, dendritic branched polymer, polymer degradation agent and solvent were compounded to obtain the polymer-containing production fluid rapid demulsifier of the present invention.

[0024] Table 1

[0025]

[0026] Application effect:

[0027] The polymer-containing production fluid demulsifiers prepared in Examples 1-4 are used for the demulsification of the polymer-containing production fluid, and the water-in-oil emulsion can be destroyed by using the demulsifier to realize oil-water separation.

[0028] Source of crude oil production fluid: production fluid from a polymer-bearing oilfield in Bohai Sea, crude oil polymer content 30-100mg / L, viscosity 591.8-2343mPa·s, density 950.8-971.5kg / m 3 (20°C), with a comprehensive water content of 75%, tested its application effect, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com