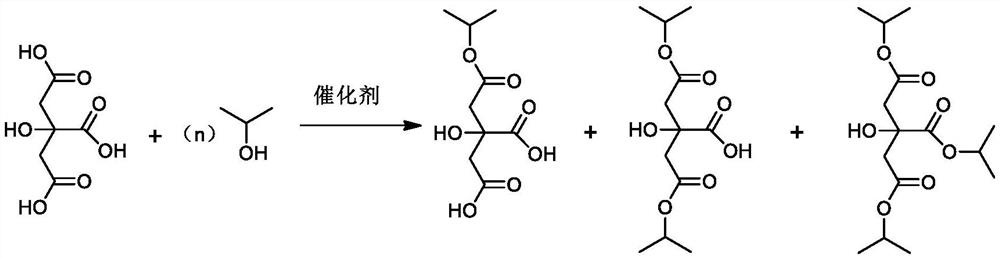

Preparation method of isopropyl citrate

A technology of isopropyl citrate and citric acid, which is applied in the field of preparation of isopropyl citrate, can solve problems such as equipment corrosion, strong acidity of concentrated sulfuric acid, hidden safety hazards, etc., achieve mild esterification reaction conditions, improve reaction efficiency, Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example provides a method for preparing immobilized p-benzenesulfonic acid.

[0051] Take 20g of sodium alginate, 50g of polyvinyl alcohol, and 5g of p-toluenesulfonic acid and add them to 400mL of purified water, mix them evenly, and heat them in a constant temperature water bath at 90°C to dissolve them completely. After cooling to about 35°C, add 400mL of Add 2% calcium chloride solution dropwise to the above solution and keep stirring slowly. After the dropwise addition, place the reaction solution at 4°C for cross-linking for 24 hours, take it out, filter, dry under reduced pressure at 45°C for 5 hours, and pass through 60 mesh Sieve out fine particles to obtain immobilized p-toluenesulfonic acid.

Embodiment 2-3

[0053] This example provides a method for preparing immobilized p-benzenesulfonic acid.

[0054] The difference with Example 1 is that in this example, the mass ratio of sodium alginate, polyvinyl alcohol and p-benzenesulfonic acid is 1:10:1 (Example 2), 7:10:1 (Example 3) .

Embodiment 4

[0056] This example provides a method for activating a strong acid cation exchange resin.

[0057] Add 100g of strong acid cation exchange resin to 200mL of 5% sodium hydroxide and soak for 30min, wash with water until neutral, add 300mL of 5% hydrochloric acid to activate and soak for 30min, add purified water to wash until the effluent is neutral, filter, and vacuum dry at 50°C. Instantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com