Preparation method of geosynthetic material prestressed reinforced assembly type solidified muck block

A geosynthetic material and prestressing technology, applied in the field of building materials, can solve the problems of low utilization rate of muck resources, high disposal cost, environmental pollution, etc., and achieve the effects of low cost, simple and convenient construction, and great economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

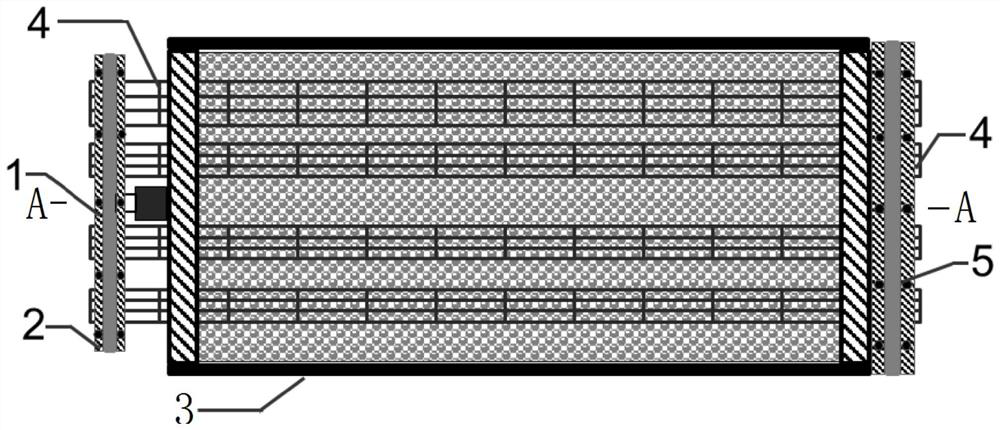

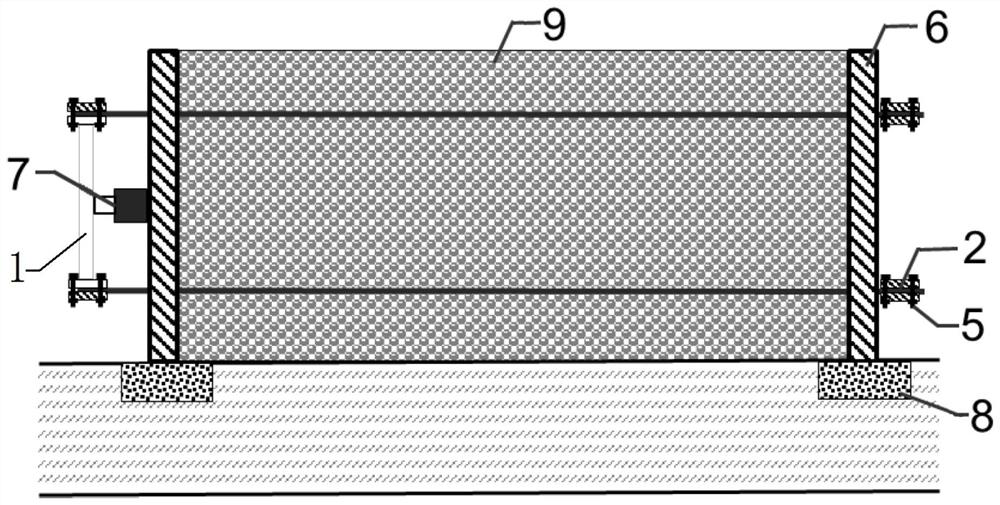

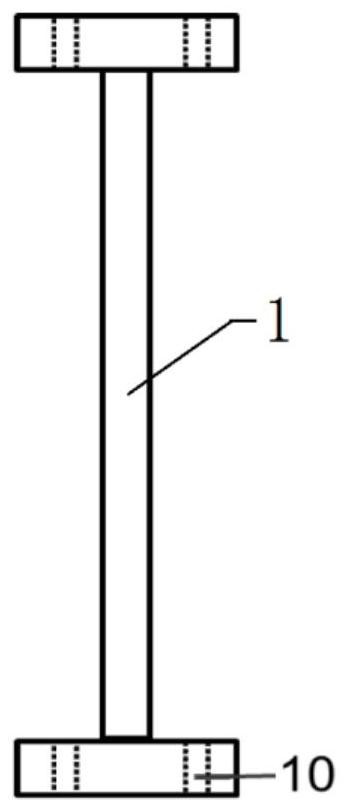

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] refer to Figure 1 to Figure 6 As shown, the preparation method of the geosynthetics prestressed reinforcement in an embodiment provided by the present invention can be assembled solidified dregs module, comprising the following steps:

[0022] 1) Breaking the engineering dregs, adding water and stirring to a fluid state to form the dregs raw materials;

[0023] 2) Add water and stir the processed muck raw material and curing agent evenly, heat for a period of time and cool down, then add foaming agent and stir evenly to form light solidified soil;

[0024] 3) pouring the prepared lightweight solidified soil into a mold provided with a prestressed geogrid;

[0025] 4) After the strength of the solidified soil reaches the predetermined value, the excess geogrids on both sides are cut off to complete the prestressed tension. After simple mainte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com