Fly ash cementing material as well as preparation method and application thereof

A technology for cementing materials and fly ash, applied in the field of concrete, can solve the problems of slow solidification reaction speed, excessive chloride ion concentration, poor strength of cementitious materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

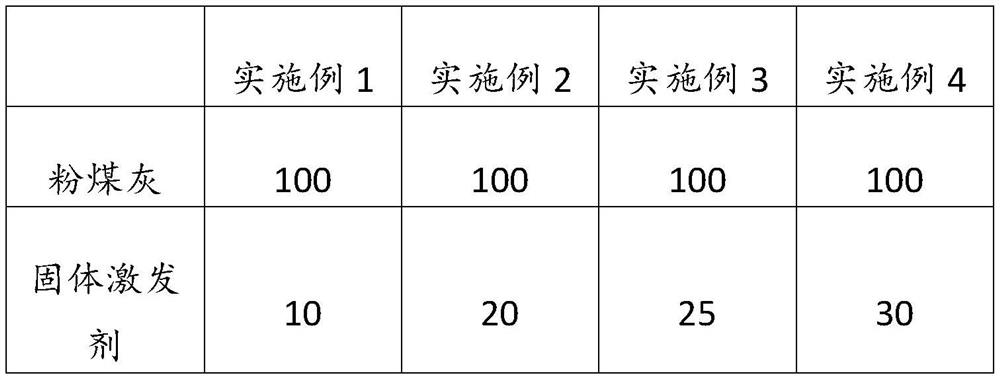

Embodiment 1

[0022]Example 1-4 The solid excitation agent is prepared by the method of the first embodiment of CN20161156603.6, as follows: raw materials: sodium hydroxide, soda glass (modulus 3.2, Wom 37), Sodium aluminate; method: (1) 100 g of sodium hydroxide, 10 g of aluminate sodium sodium aluminate in 890 g of sodium aluminate, mixed with 20 min, to give a mixed solution; (2) under the conditions of water bath The stirring solution reduced the system temperature to room temperature; (3) added 2G seed crystals, continued to stir 8min, showed a sharp temperature rise, and poured a mixed solution into a clean plastic plane tray, cured 3 min, to obtain a block solid The excitation agent; (4) crushing the block excitation agent, screened, taking the powder under the 100 mesh sieve is No. 1 solid excitation agent, stores for use; (5) No. 1 solid excitation is stored for 3 months, A 150 g of solid excitation, 1500 g of fly ash and 150 g of water to the mixing mixer were weighed, and the mixture w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com