Product telescopic lifter

A lifter and product technology, applied in the direction of lifting frame, lifting device, lifting equipment safety device, etc., can solve the problems of huge quantity, waste of time, affecting the health of staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

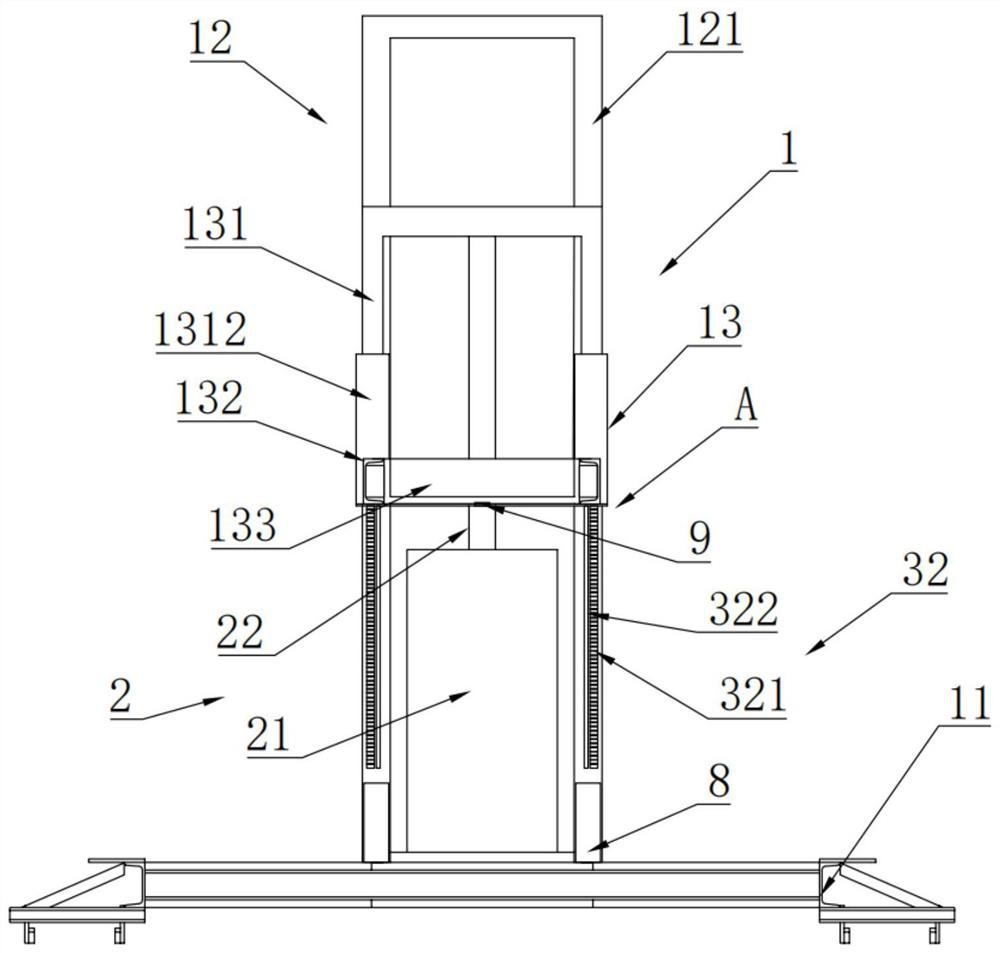

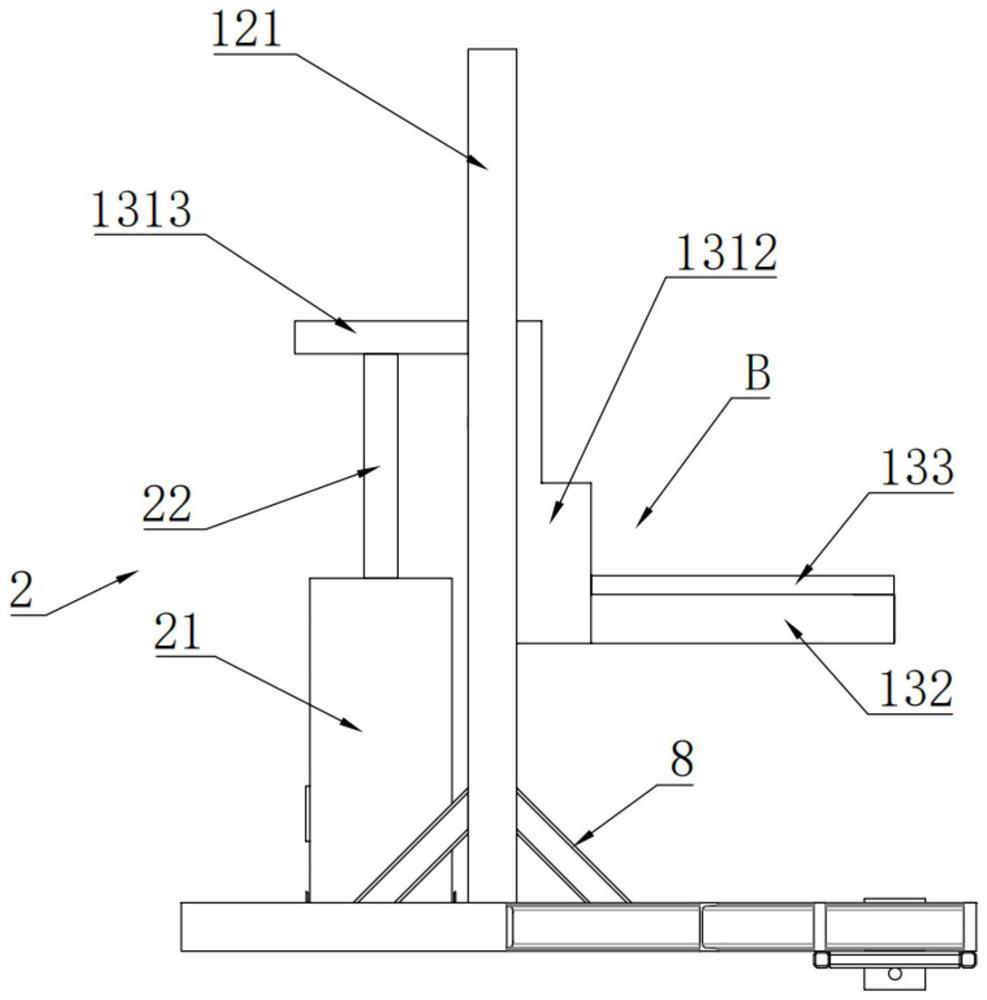

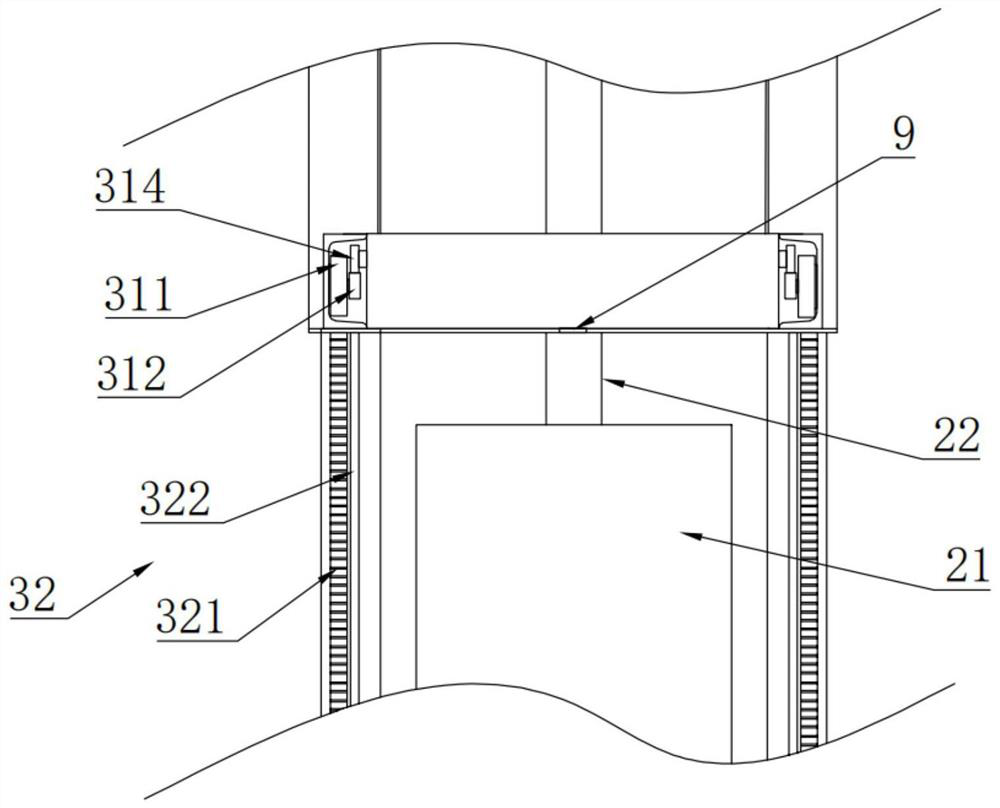

[0024] refer to Figure 1-9 As shown, a product telescopic lifter of this embodiment includes a fork frame 1, a lifting assembly 2, a linkage assembly 3 and a detection assembly 9, and the fork frame 1 includes a base 11, a support frame 12 and a shelf 13, The bottom of the support frame 12 is fixedly connected with the base 11, the elevating assembly 2 is fixedly connected on the base 11, and one end of the elevating assembly 2 is fixedly connected with the rack 13 to drive the rack 13 to move up and down. When the storage rack 13 descends to the bottom, the staff can put the products that need to be picked up, such as rolled thread products, on the storage rack 13, and use the lifting assembly 2 to raise the storage rack 13 to a suitable height for the staff. It is necessary for the staff to bend down every time to pick up the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com