Dust removal device

A dust removal device, No. 1 technology, applied in the direction of dust removal, loading/unloading, transportation and packaging, etc., can solve the problems of inconvenient dust removal position adjustment, inconvenient dust and efficient water spraying and dust reduction treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

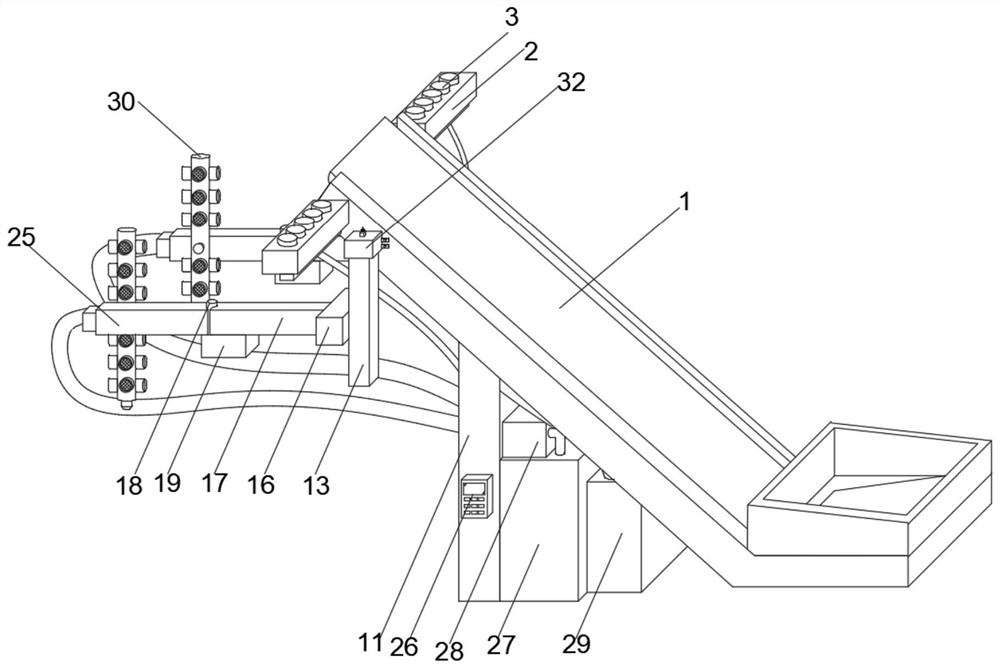

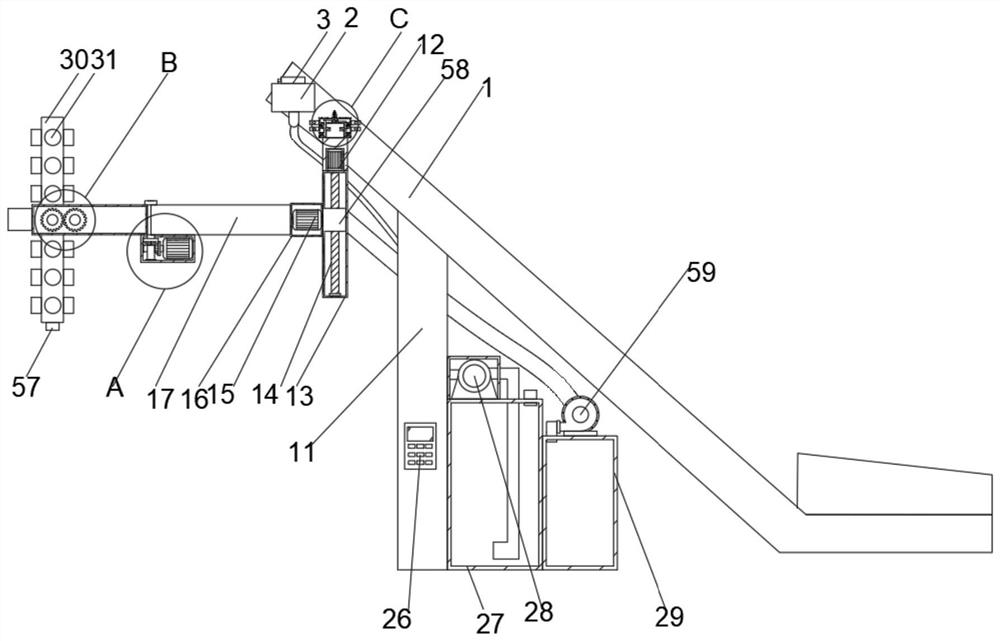

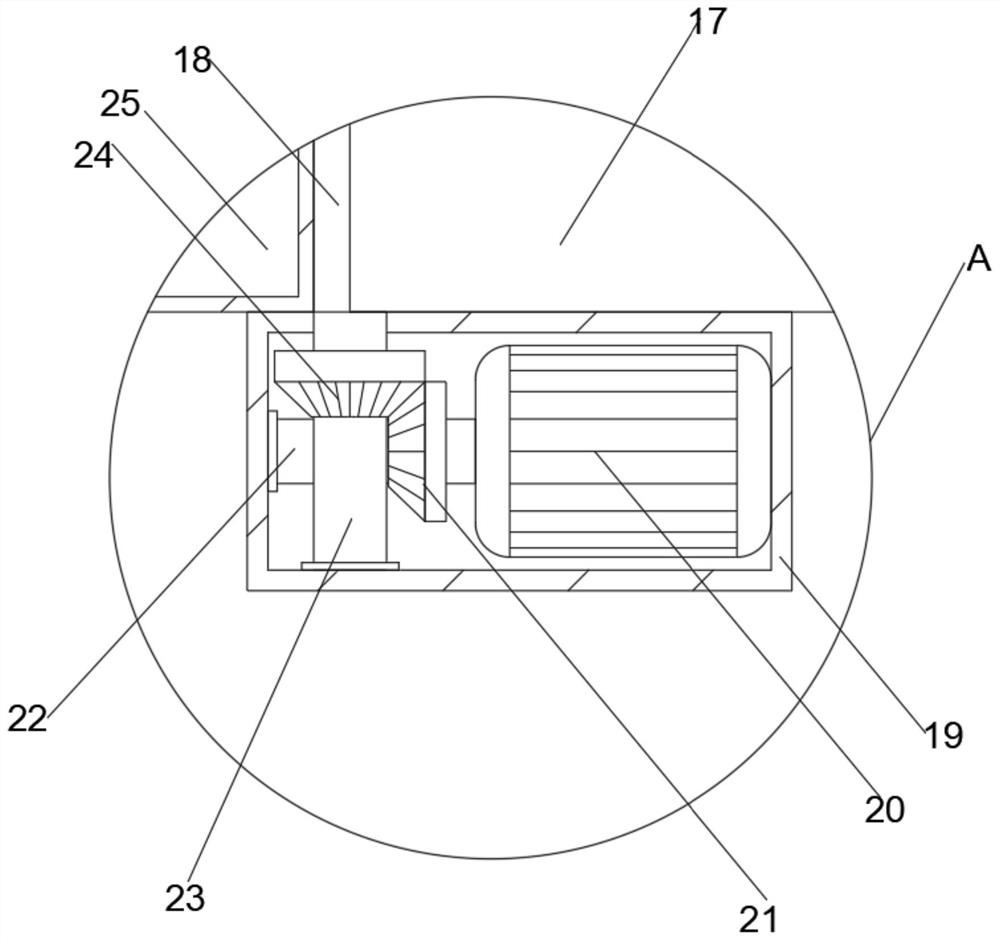

[0031]Example:Figure 1-7, A dust removing device includes a conveyor 1, a strut 11, and a water storage tank 27 having a water storage tank 2, and a water pump 28 is provided on one side of the pilla sheet 27, and the water pump 28 is passed through. The water pipe is connected, and both sides of the conveyor 1 are provided with a connection box 2, and the inner portion of the 1 tank 2 is provided with a cylinder 5, and the output of the cylinder 5 is fixedly connected to the rack 6, and the rack 6 and one connection box are connected. 2 Slide the connection, the top of the first connection box 2 is rotatable with five water tanks 3, and the water spray tank 3 is provided with a water sprinkler 4, and there is a through water rod 10 at the bottom of the water tank 3, and The water rod 10 is rotated from the 1-tank 2, and the outer side of the water rod 10 is fixedly connected to the first gear 9, and the first gear 9 is engaged with the rack 6, and a second connection box is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com