Automatic straw sticking machine

A tube machine and automatic technology, applied in packaging and other directions, can solve the problems of lower production efficiency, slow production line speed, complicated production process, etc., and achieve the effect of reducing the use of labor, improving production efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

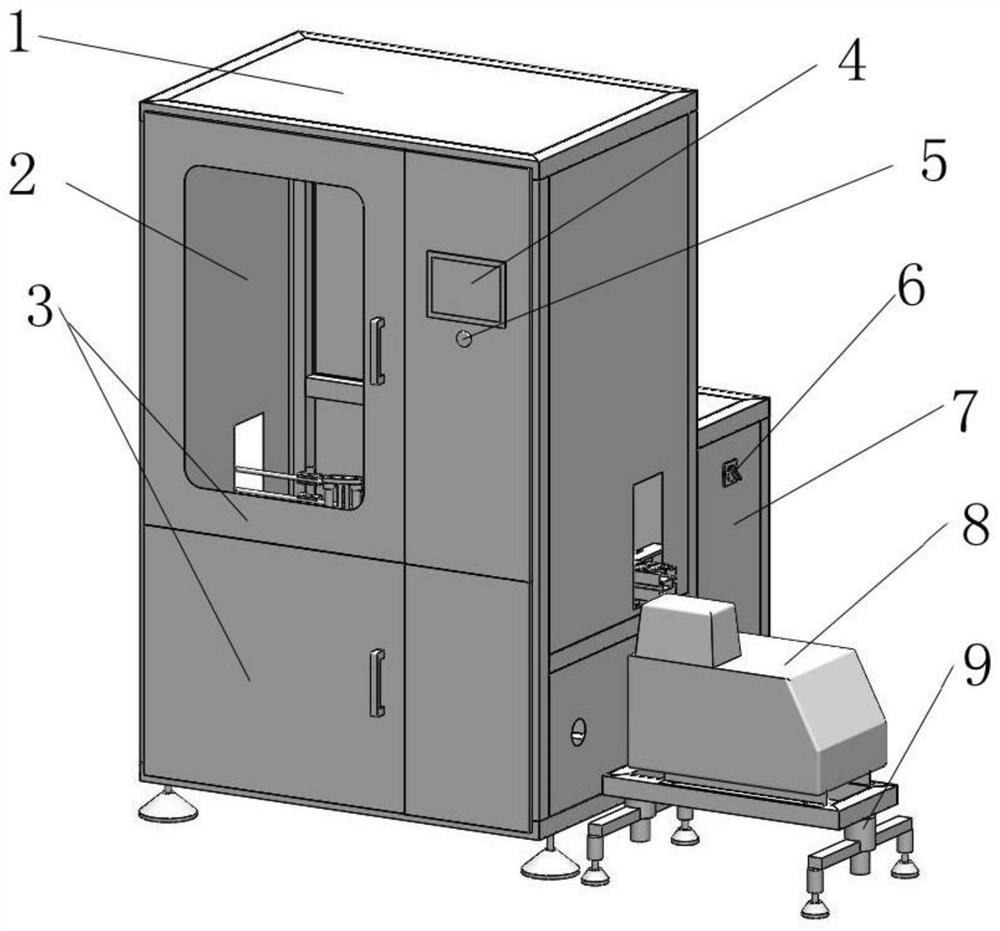

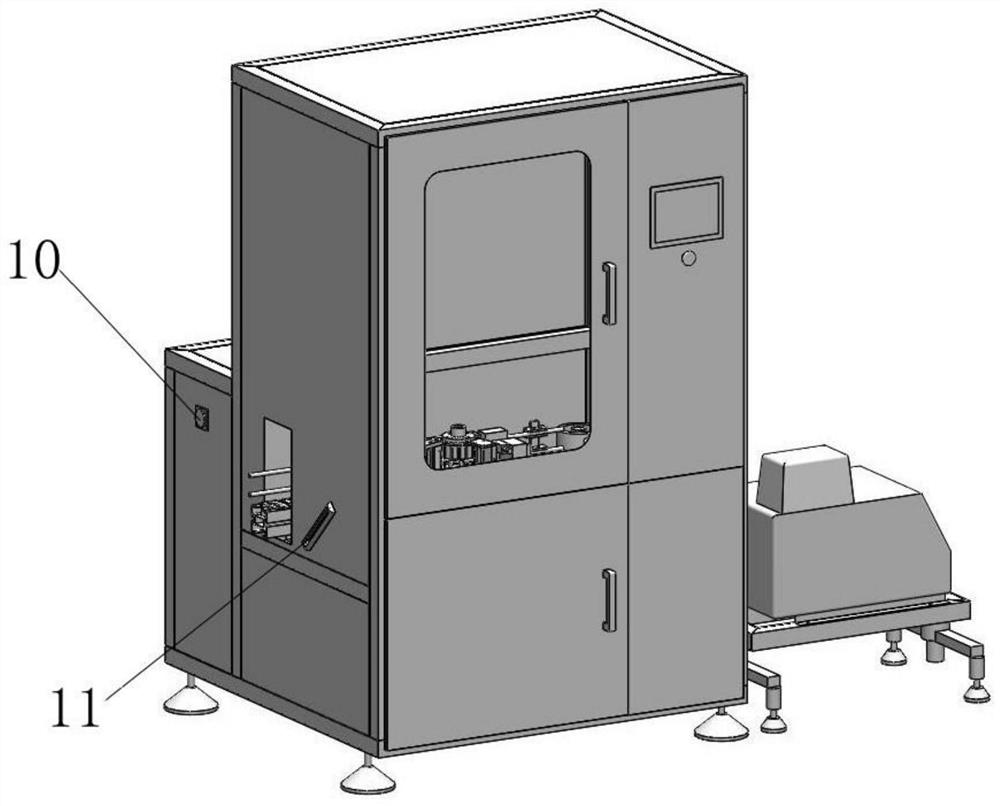

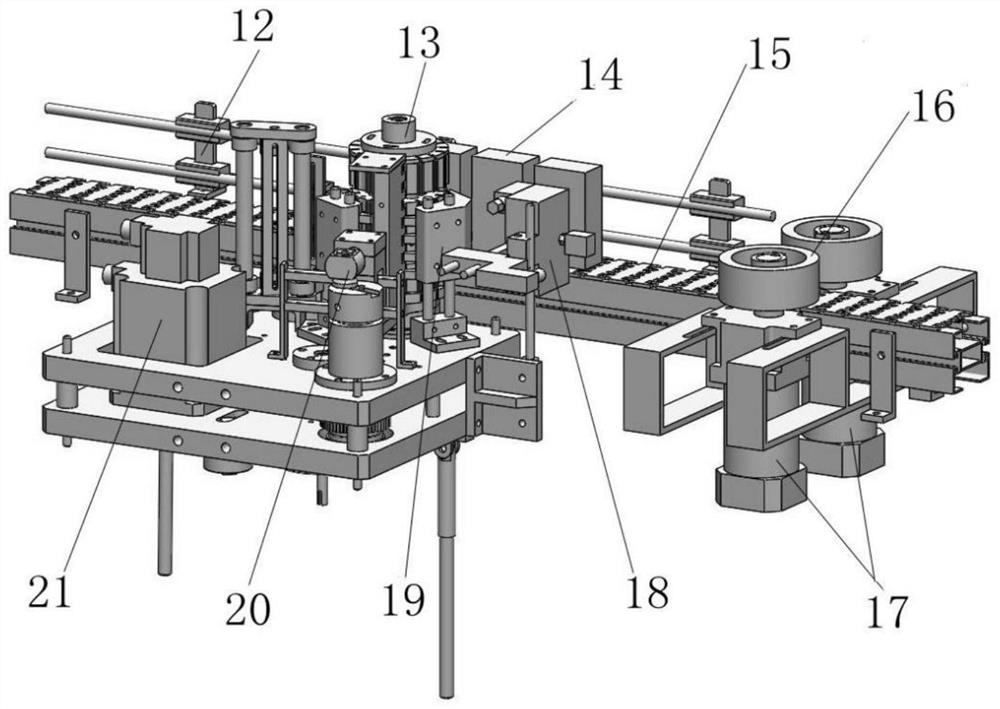

[0022] Such as Figure 1-Figure 4 As shown, the automatic tube sticking machine provided in this embodiment includes a body 1 and a drum assembly 13 installed inside the body 1. One side of the drum assembly 13 is provided with an in-machine conveyor chain 15, and the in-machine conveyor chain 15 There are multiple cartoning motors 17 slidingly connected to the lower part through two sets of support frames. The output end of the cartoning motor 17 is connected to the wheel box 16. The drum assembly 13 includes a tube sticking base 25 and a servo motor installed inside the tube sticking base 25 One side of the motor 21 and the drum assembly 13 is provided with a glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com