Curved surface fitting drum design method and curved surface fitting drum

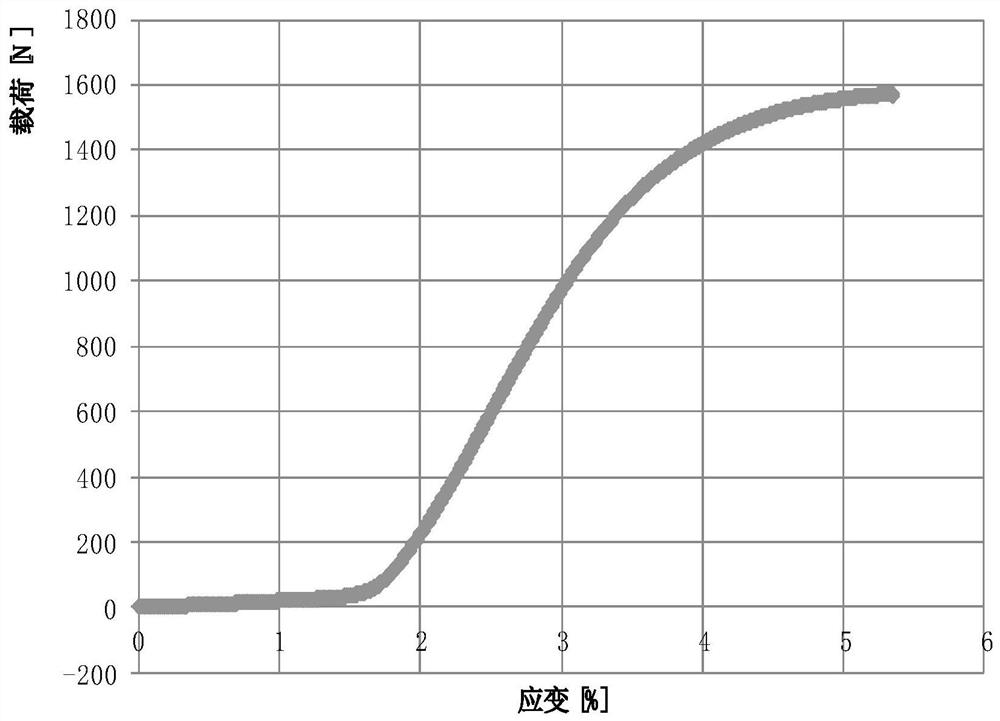

A design method and drum-fitting technology, applied in vehicle parts, transportation and packaging, reinforcement layers of pneumatic tires, etc., can solve problems such as uneven stress on tire crown components and inability to ensure consistent tension of 0° reinforcement plies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

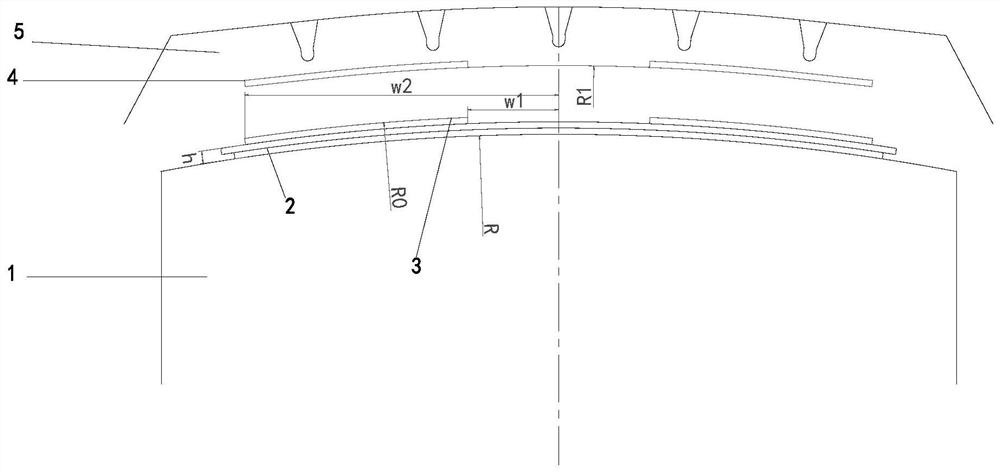

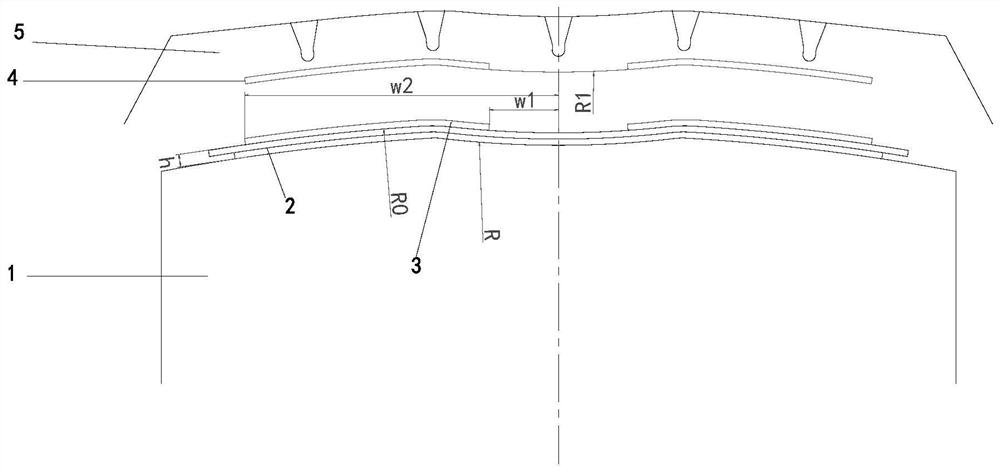

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the application with reference to the drawings in the embodiments of the application. Apparently, the described embodiments are only some of the embodiments of the application, not all of them. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of this application.

[0034] As mentioned in the background, the traditional method works by placing tension on the 0° reinforcement ply, which does exist when on the laminating drum, but when unloaded from the tire assembly equipment these stresses are released and the released tire assembly This will cause the crown to collapse in the radial direction, thereby changing the relative displacement of the various components of the tire assembly, especially the added ply.

[0035] In order to solve the above proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com