A kind of manufacturing method and pcb of slot bottom via hole solder resistance plug

A production method and solder mask technology, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of uneven force, uneven oil leakage from plug holes, etc., and achieve uniform oil leakage, good alignment, Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

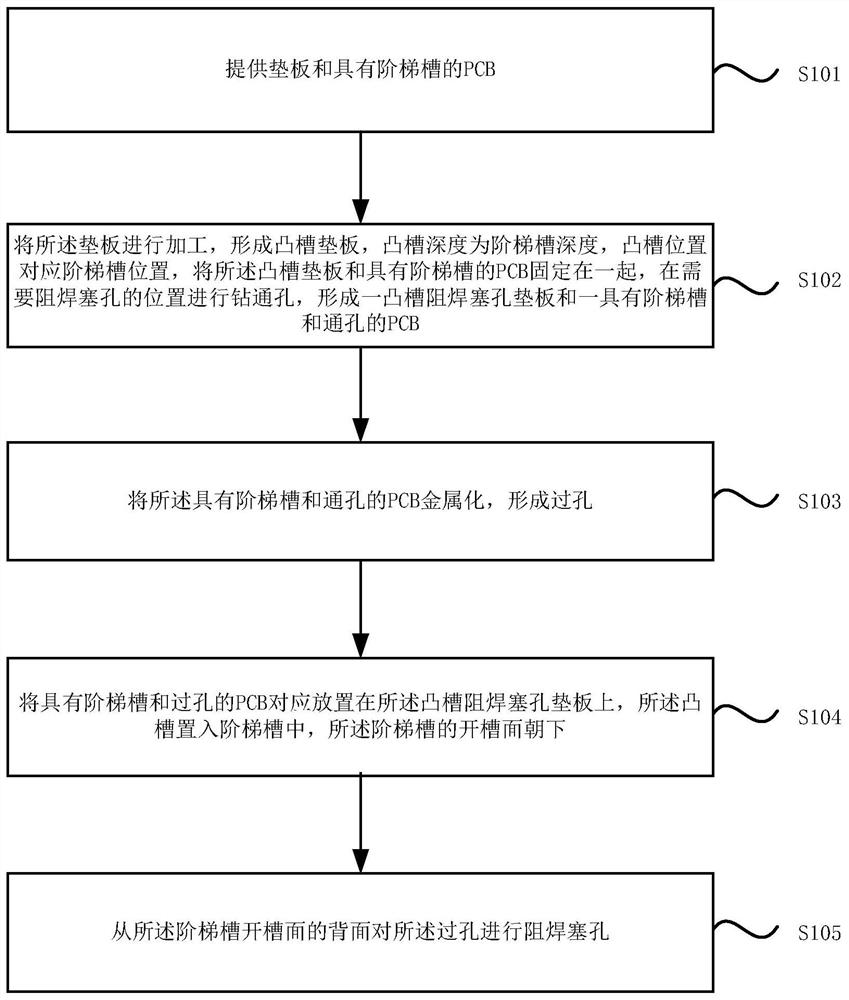

[0053] see figure 1 , the present embodiment 1 provides a method for making a solder resist plug hole in a groove bottom via, which specifically includes the following steps:

[0054]S101. Provide a backing plate and a PCB with stepped grooves.

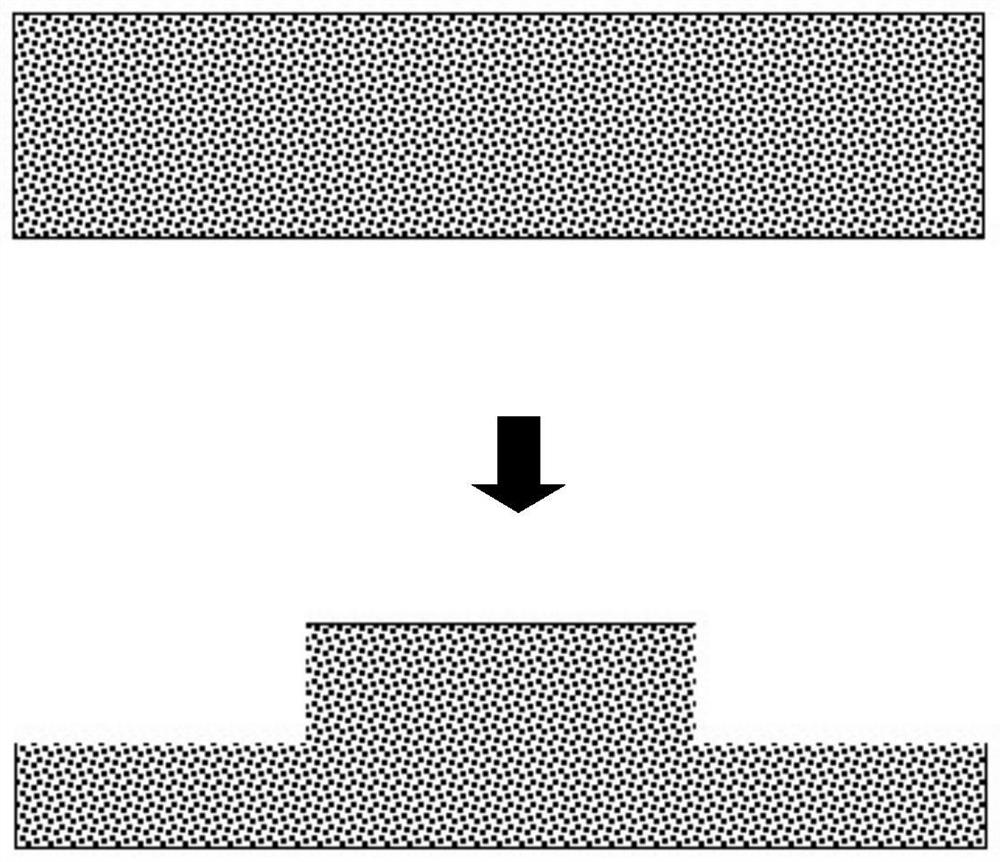

[0055] S102. Process the backing plate to form a convex groove backing plate, the depth of the convex groove is the depth of the stepped groove, and the position of the convex groove corresponds to the position of the stepped groove, and the convex groove backing plate and the PCB with the stepped groove are fixed together. Drill through holes at positions where solder resist plug holes are required to form a convex groove solder resist plug hole backing plate and a PCB with stepped grooves and through holes.

[0056] It should be noted that the cross section of the convex groove is aligned with the center of the stepped groove of the PCB, and is smaller than or equal to the size of the stepped groove.

[0057] By drilling the holes...

Embodiment 2

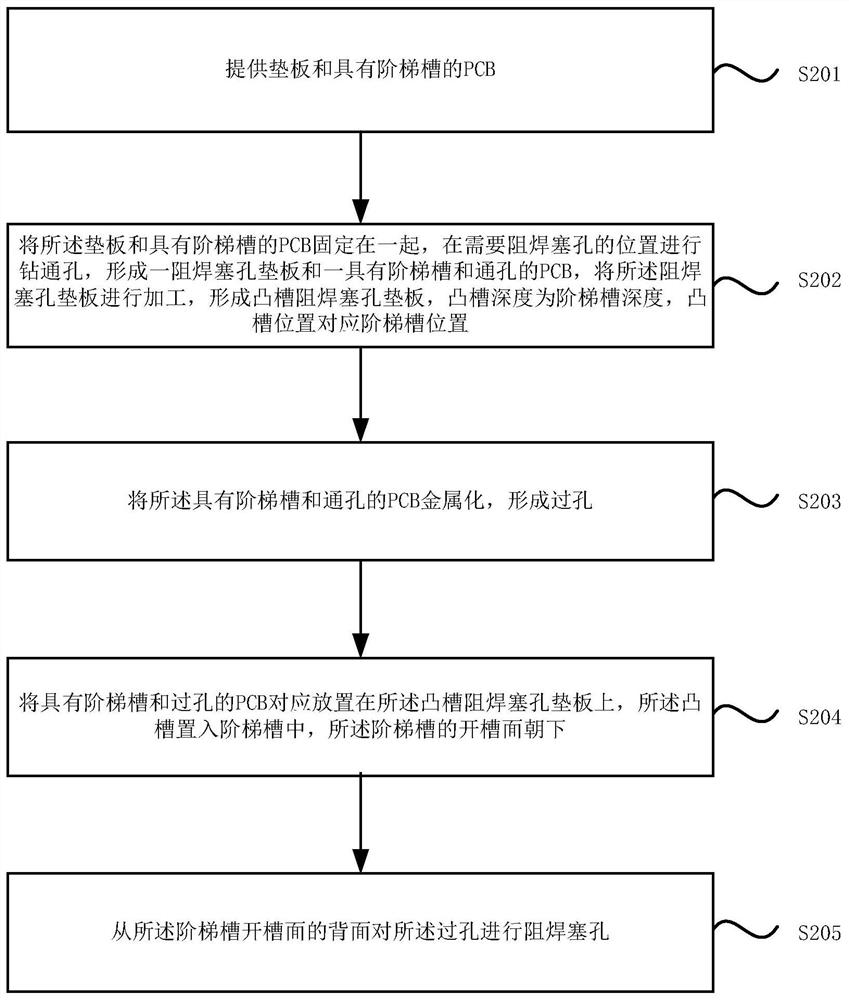

[0082] like figure 2 As shown, the manufacturing method of the groove bottom via hole solder resist plug hole provided by the second embodiment of the present invention is based on the technical solution provided by the first embodiment, and the step S102 "processing the backing plate to form a convex groove Backing plate, the depth of the convex groove is the depth of the stepped groove, and the position of the convex groove corresponds to the position of the stepped groove. Fix the convex groove backing plate and the PCB with the stepped groove together, and drill through holes at the positions where solder resist plug holes are required to form Further optimization of a raised slot solder mask plug hole backer and a PCB with stepped slots and through holes". Explanations of terms that are the same as or corresponding to the above embodiments are not repeated here. Specifically include the following steps:

[0083] S201. Provide a backing plate and a PCB with stepped groo...

Embodiment 3

[0105] The third embodiment provides a PCB, which has a slot bottom via hole of a solder resist plug hole, and the slot bottom via hole of the solder resist plug hole is manufactured according to the manufacturing method provided in the above embodiment.

[0106] Compared with the prior art, the PCB provided by the embodiment of the present invention not only solves the problem of uneven stress on the bottom of the groove and outside the groove when the hole is plugged, but also ensures that the plug hole emits oil evenly, and at the same time avoids the use of resin plug holes. The production process is long, the production efficiency is low, and the production cost is high. The production process is simpler, the efficiency is higher, and the alignment is better, which is suitable for mass production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com