Complete equipment for preparing low-oil healthy instant noodles with low energy consumption and method for producing instant noodles

A complete set of equipment, low energy consumption technology, applied in food preparation, application, food science and other directions, can solve the problems of frying oil easily deteriorated into harmful substances, increasing the production cost of instant noodles, large differences in color and oil content, etc., and meeting the requirements of plant facilities And the effect of reducing capital investment, reducing sewage and waste gas, and uniform oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] Example 2. A method for preparing low-oil healthy instant noodles by using a complete set of equipment with low energy consumption

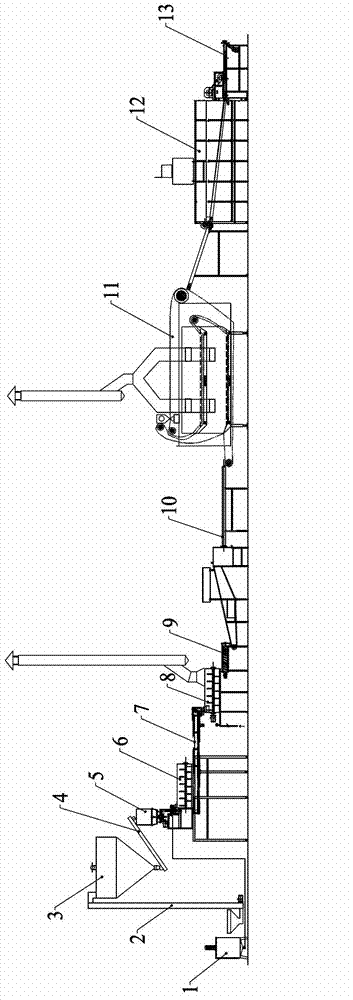

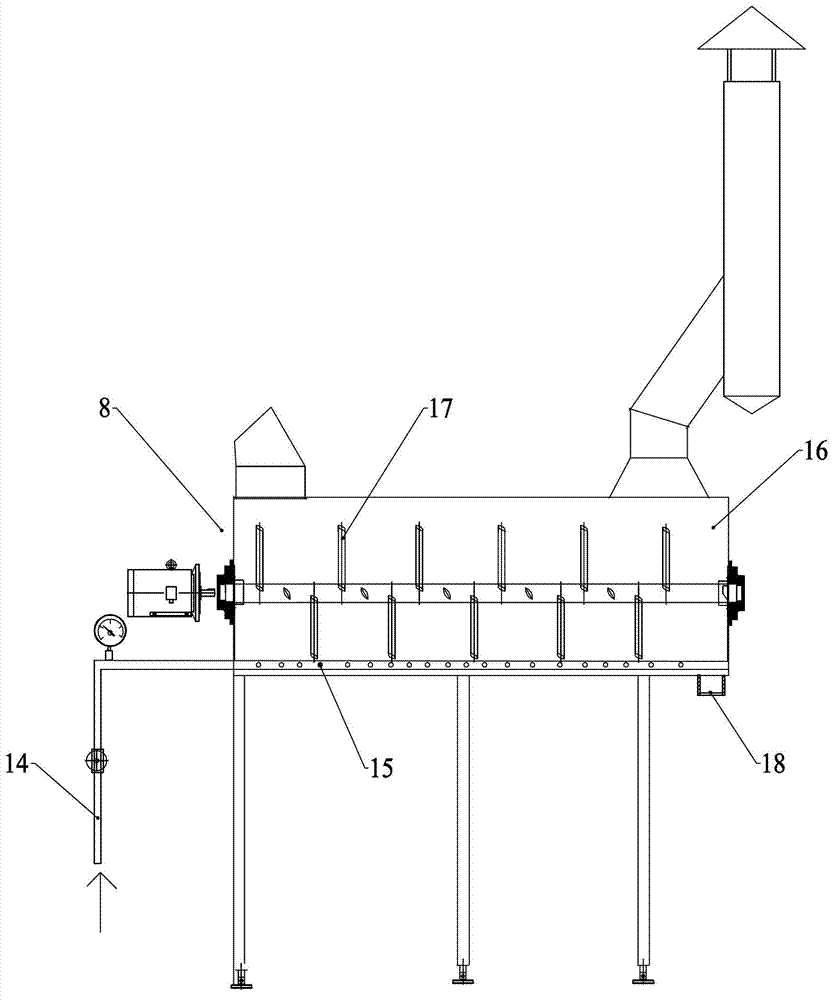

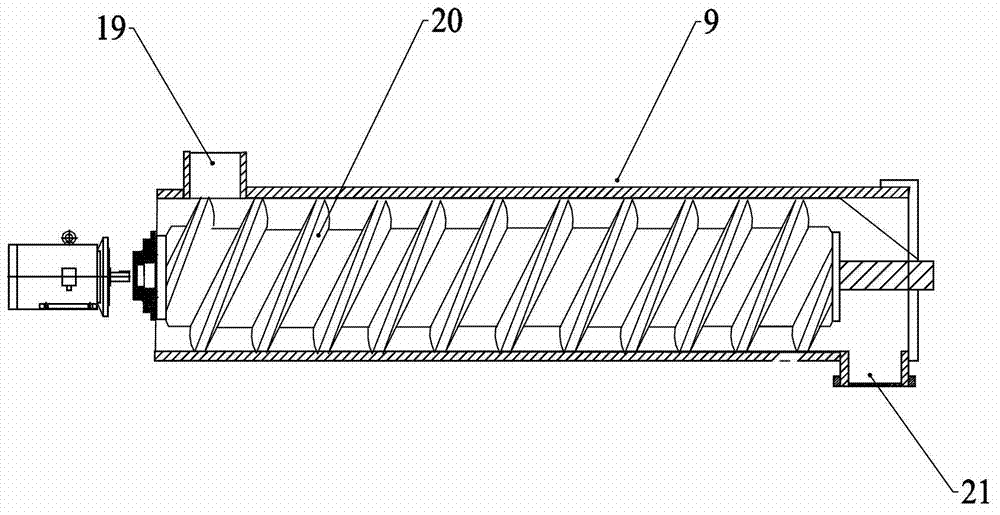

[0033] Reference Figure 1 to Figure 4 This Example 2 is a method for preparing low-oil healthy instant noodles using the low-energy complete set of equipment of Example 1. The process flow is:

[0034] Raw material supply → kneading → homogenization → dynamic waking → steaming → extruding and maturing to produce silk → quantitative cutting → double-layer frying and drying → air cooling → split conveying → packaging; among them:

[0035] A). Raw material supply process: the flour raw materials are poured into the flour elevator 2, continuously fed to the flour bin 3, and then continuously fed to the vertical continuous dough mixer 5 via the screw conveyor 4; among them, the screw conveyor The feeding speed can be adjusted and controlled to realize automatic weighing, and mix different powdered raw materials uniformly, and continuously supply pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com