Washing device for producing carbon fiber precursors

A carbon fiber raw fiber and water washing device technology, which is applied in the fields of fiber chemical characteristics, rayon cleaning/drying, textiles and papermaking, etc., can solve the problems of low efficiency, large water consumption, poor effect, etc. The effect of small amount of water and avoiding the generation of lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

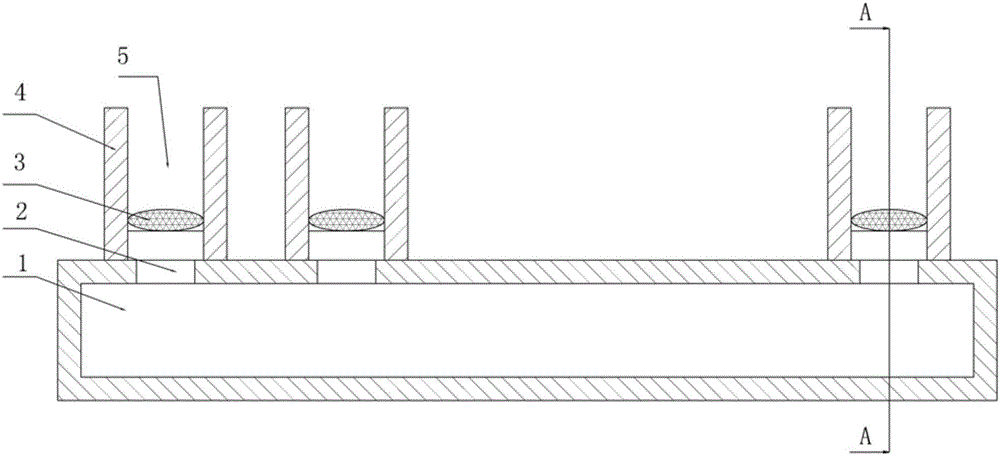

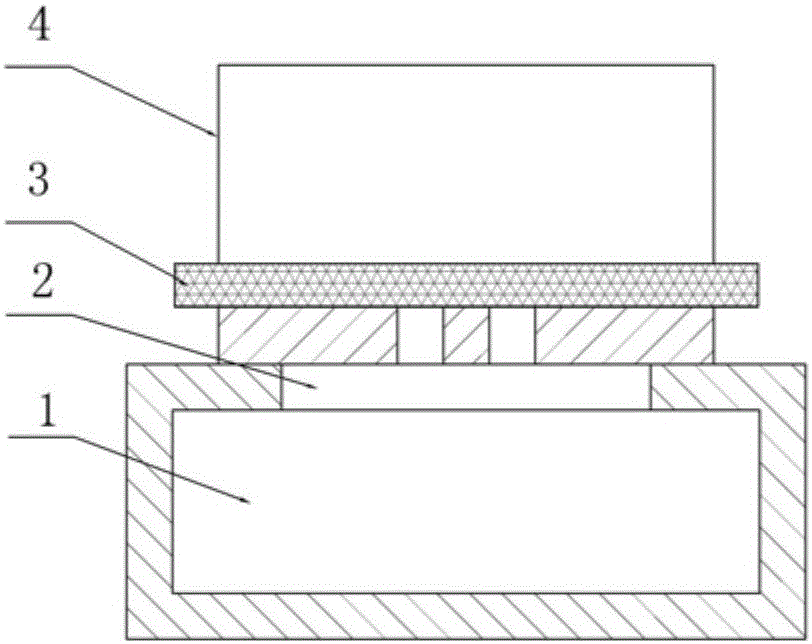

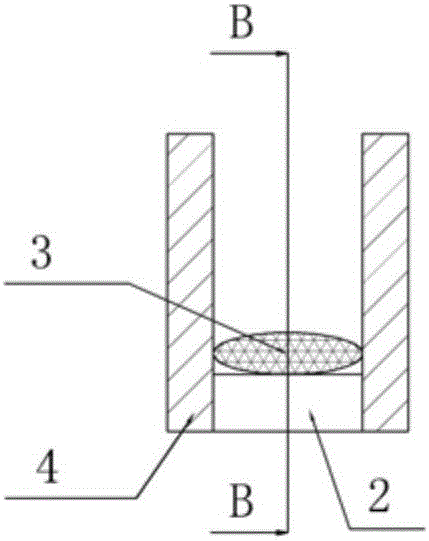

[0021] The invention is a water washing device for producing carbon fiber precursors, and the replacement medium can also be used as an oiling device in the technological process. The water washing device comprises a water tank 1, a plurality of parallel nozzles 4 are arranged on the tank body, the water inlet 2 of each nozzle communicates with the water tank, and the water outlet of each nozzle is respectively opposite to the water washing channel 5 of a bundle of carbon fiber precursors. , That is, only one bundle of filaments 3 is allowed to pass through each nozzle. Conventional products of carbon fiber precursors include 1K, 3K, 6K, 12K, 24K, 48K (50K), etc., and this technology is applicable. The nozzle is a U-shaped groove type or a flat supporting plate type, the water outlet of the nozzle is arranged on the bottom surface in the U-shaped groove, and there are two water outlets on the bottom surface in the U-shaped groove or on the flat supporting plate. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com