Novel bloom continuous casting machine emergency shutdown oil cylinder

A technology for accidental cutting and blooming, applied in the field of metallurgy, can solve the problems of increasing the labor intensity of operators, affecting the production efficiency of continuous casting machines, and difficult and time-consuming installation, so as to reduce maintenance costs and labor intensity of employees, and reduce the risk of oil leakage. , Improve the effect of safety and reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

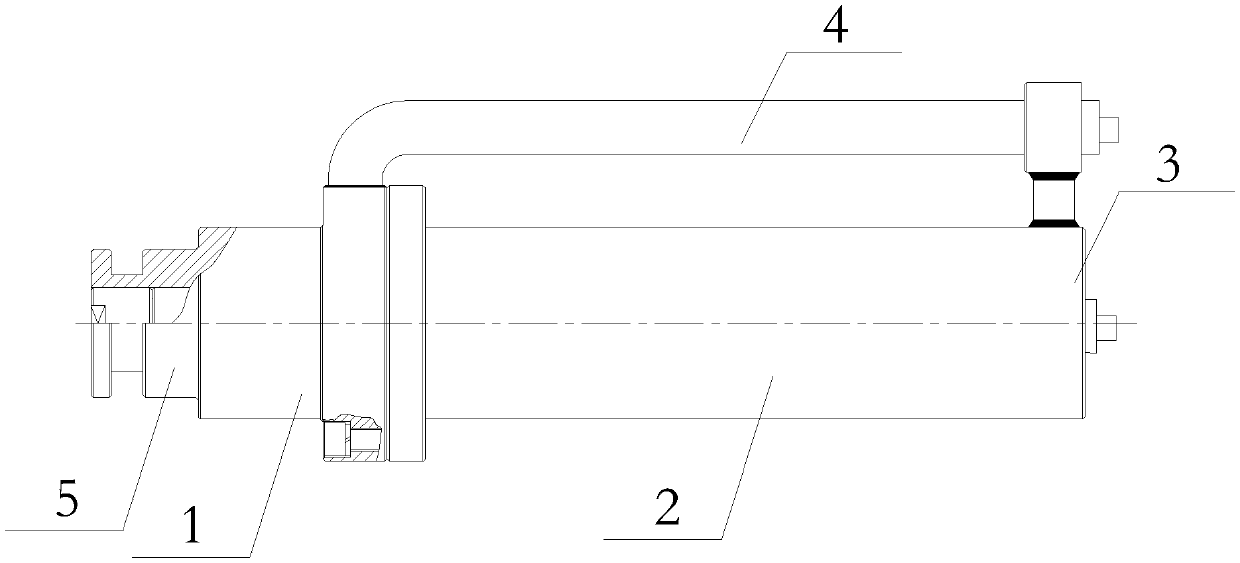

[0013] The present invention includes an oil cylinder body, and the oil cylinder body includes an oil cylinder upper flange 1, a cylinder body 2, and an oil cylinder lower flange 3 that are fixedly connected to each other;

[0014] One end close to the upper flange 1 of the oil cylinder is fixedly equipped with an oil cylinder hanger 4; the upper flange 1 of the oil cylinder and the hanger 4 of the oil cylinder are designed as one, and the cylinder body 2 and the lower flange 3 of the oil cylinder are designed as one, which can be Reduce the number of two seals and reduce the risk of oil leakage.

[0015] A piston 5 is pierced inside the upper flange 1 of the oil cylinder, the cylinder body 2 and the lower flange 3 of the oil cylinder; the piston 5 can be a fixed piston 5 or a movable stopper rod 5 .

[0016] The upper flange 1 of the oil cylinder, the cylinder body 2 and the lower flange 3 of the oil cylinder are connected by four through-length screws.

[0017] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com