A digital intelligent vertical and horizontal sawing production line

A production line and edge sawing technology, which is applied to circular saws, sawing components, sawing equipment, etc., can solve the problems of large space occupation, low processing efficiency, and inability to cut wood boards, so as to save processing space, improve processing efficiency, shorten The effect of the conveying stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

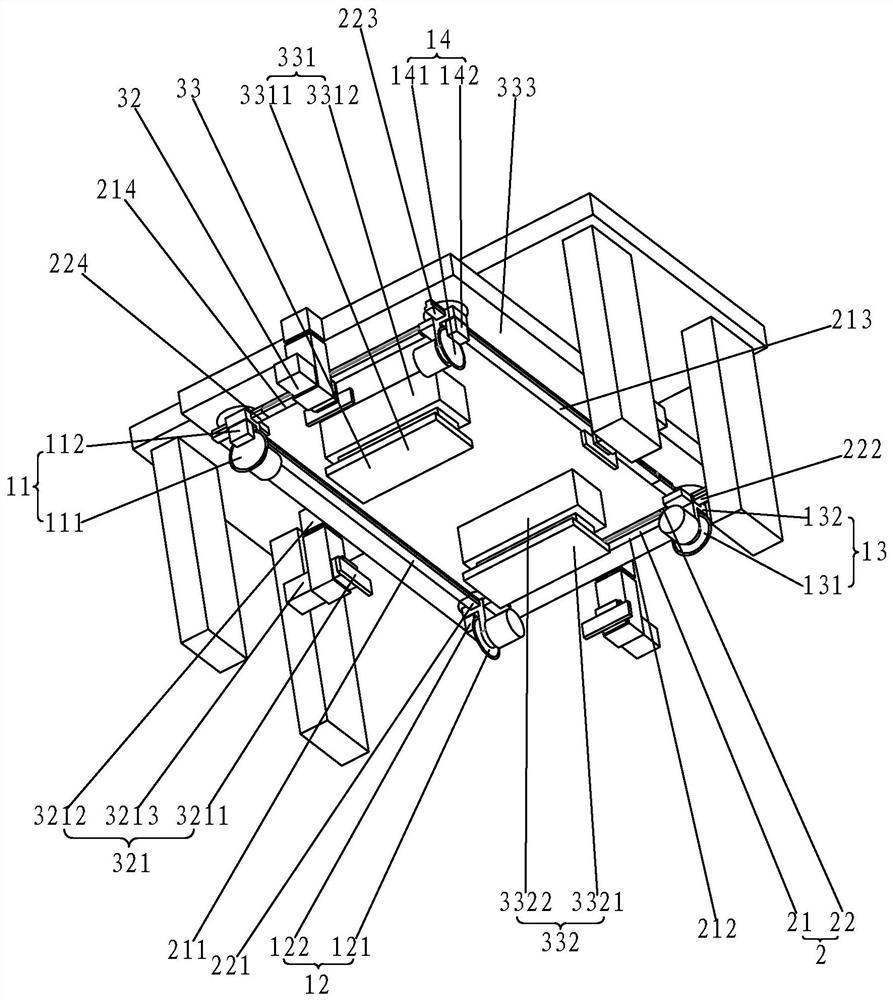

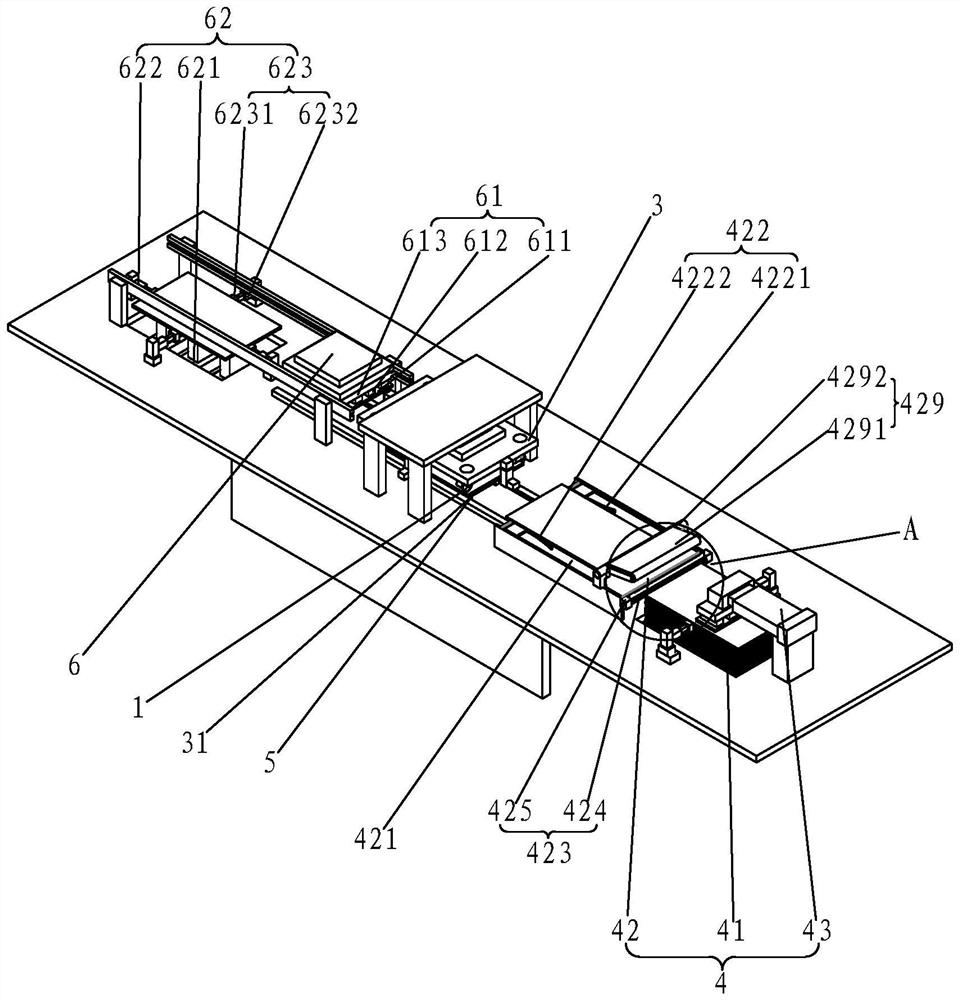

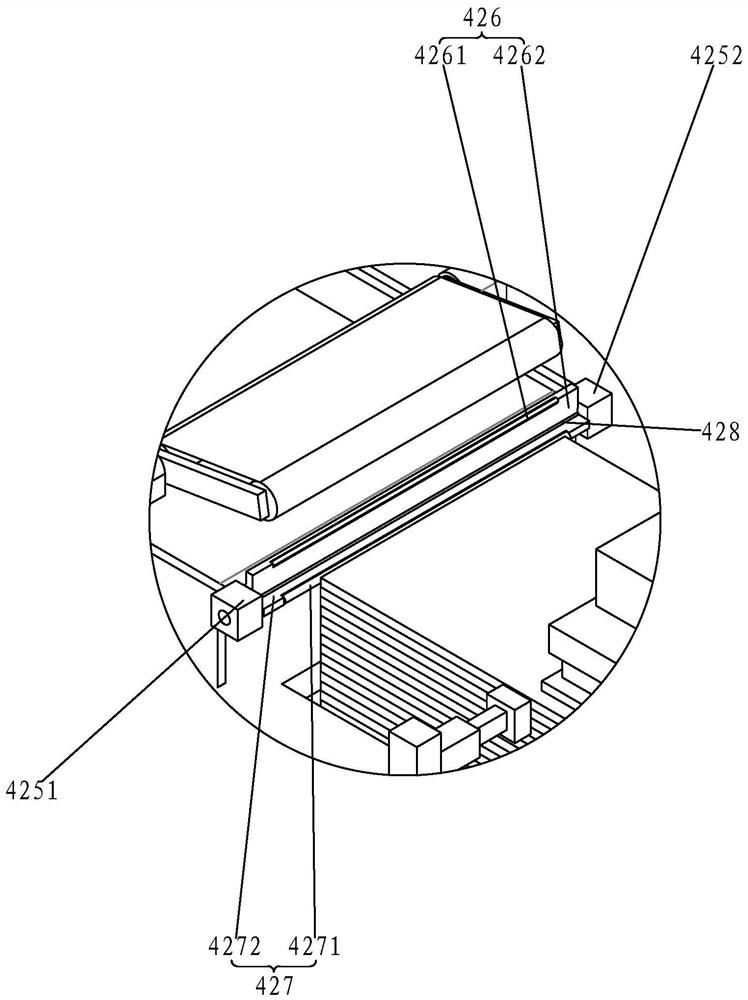

[0049] like Figure 1 to Figure 3 As shown in the figure, a digital intelligent vertical and horizontal sawing production line of the present invention includes a sawing device for sawing the four sides of a wooden board; The guide mechanism 2 for moving the outer periphery of the wooden board; the sawing mechanism 1 includes a first cutting device 11, a second cutting device 12, a third cutting device 13 and a fourth cutting device 14 for cutting four sides of the wooden board respectively; the first cutting device 11, the second cutting device 11, the second cutting device 12 The cutting device 12 , the third cutting device 13 and the fourth cutting device 14 are slidably connected with the guide mechanism 2 .

[0050] In this way, through the first cutting device 11 , the second cutting device 12 , the third cutting device 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com