Paper supporting mechanism for large automatic carton pasting and nailing machine

A nail box machine and automatic technology, which is applied in the field of paper supporting mechanism of large-scale automatic gluer and nail box machine, can solve the problems of high waste rate, low cardboard folding accuracy, inconvenient cleaning of waste residue on cardboard, etc., so as to reduce the waste rate , shorten the conveying stroke, reduce the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

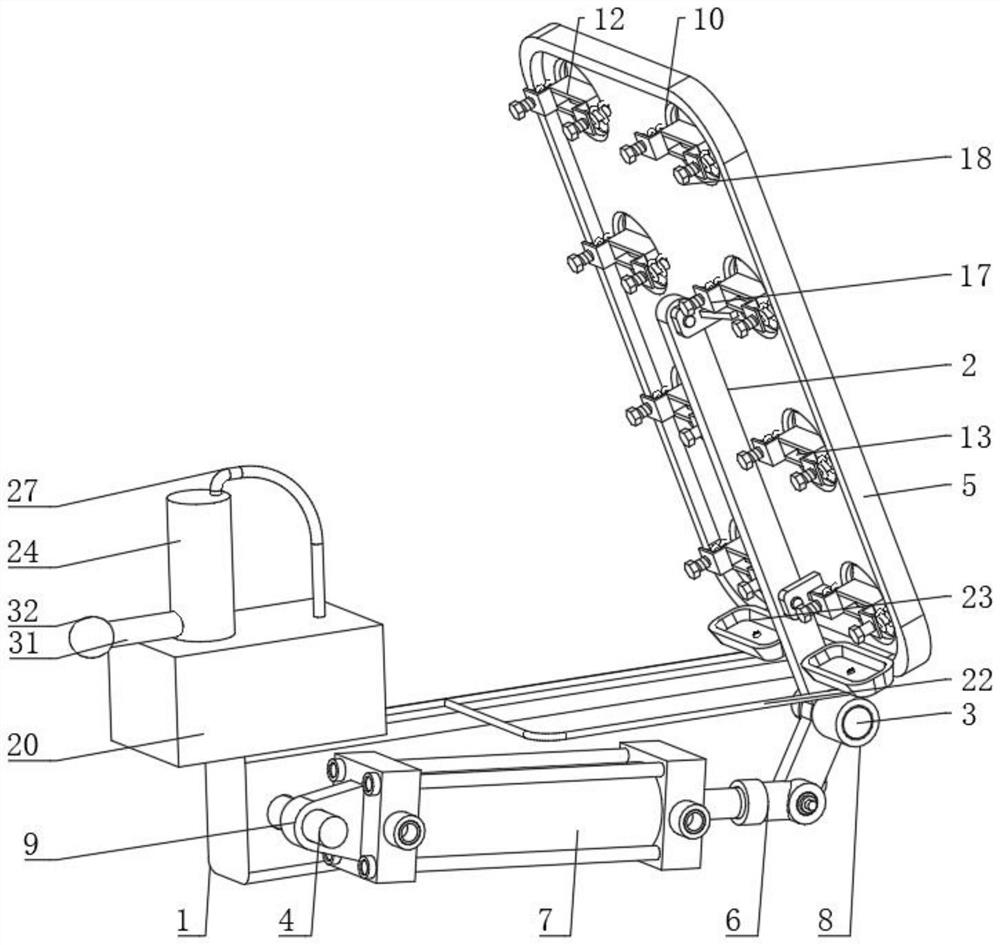

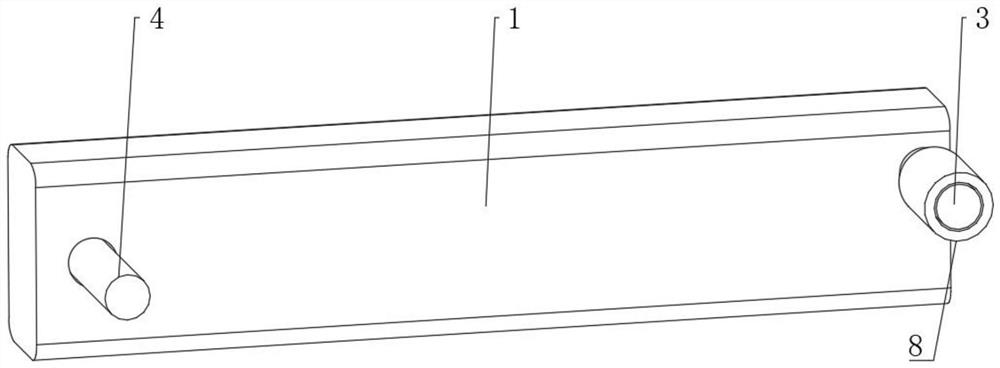

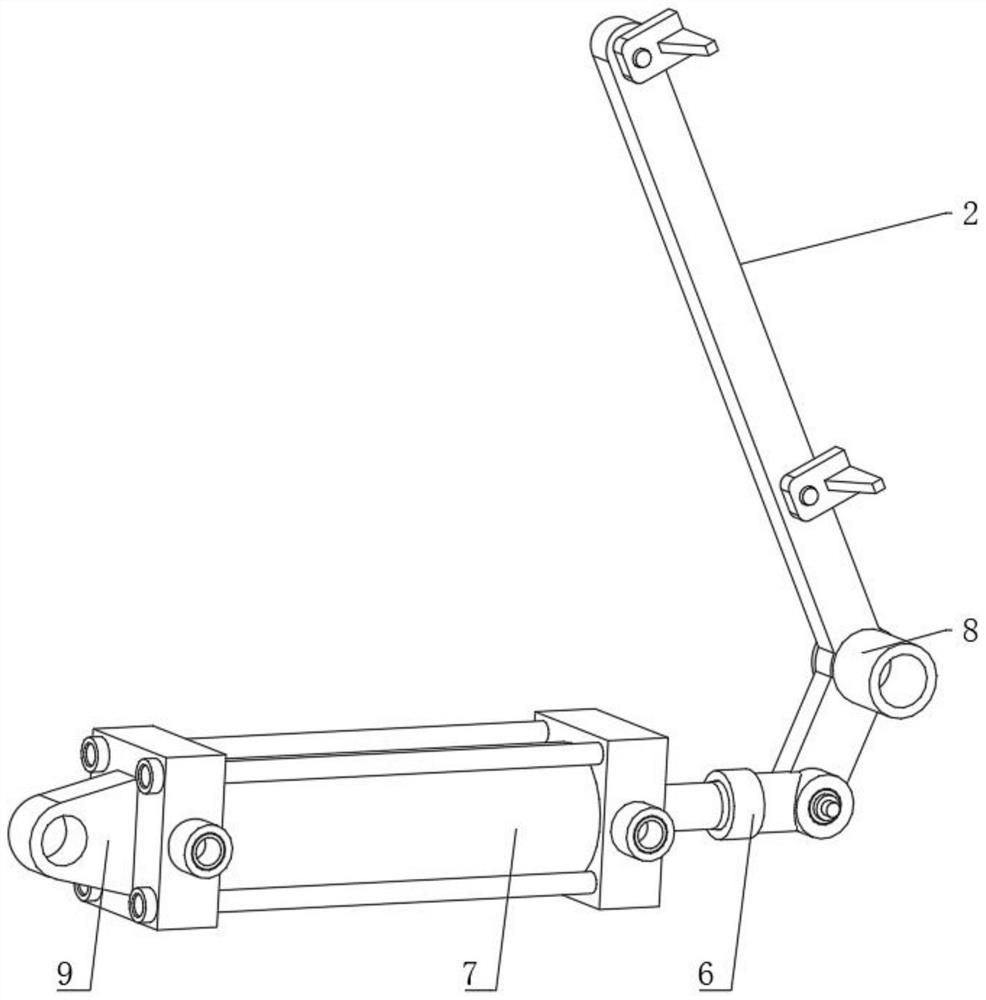

[0038] see Figure 1-8 , a large-scale automatic gluer and nail box machine supporting paper mechanism, including a cylinder support 1, one end of the cylinder support 1 is rotatably mounted with a second support shaft 4, the second support shaft 4 is equipped with a cylinder seat 9, and the cylinder seat 9 is far away from the first One end of the two support shafts 4 is equipped with a cylinder 7, and the cylinder 7 is controlled by a computer with a solenoid valve air circuit. This technical solution is a prior art, not shown in the figure, and the other end of the cylinder support 1 is rotated and installed with a first support shaft 3 , the outer side of the first support shaft 3 is equipped with a bearing 8, the outer side of the bearing 8 is equipped with a crutch 2, the end of the crutch 2 away from the cylinder bracket 1 is fixedly installed with a support plate 5, and the support plate 5 is provided with a slag discharge mechanism to support The lower end of the boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com