Unmanned and waste-free digital complete-set production line for rectangular plates

A rectangular plate and production line technology, applied in the direction of sawing machine, sawing machine accessories, metal sawing equipment, etc., can solve the problems of manual positioning and feeding trouble, low processing efficiency, unfavorable work efficiency, etc., and achieve precise position adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

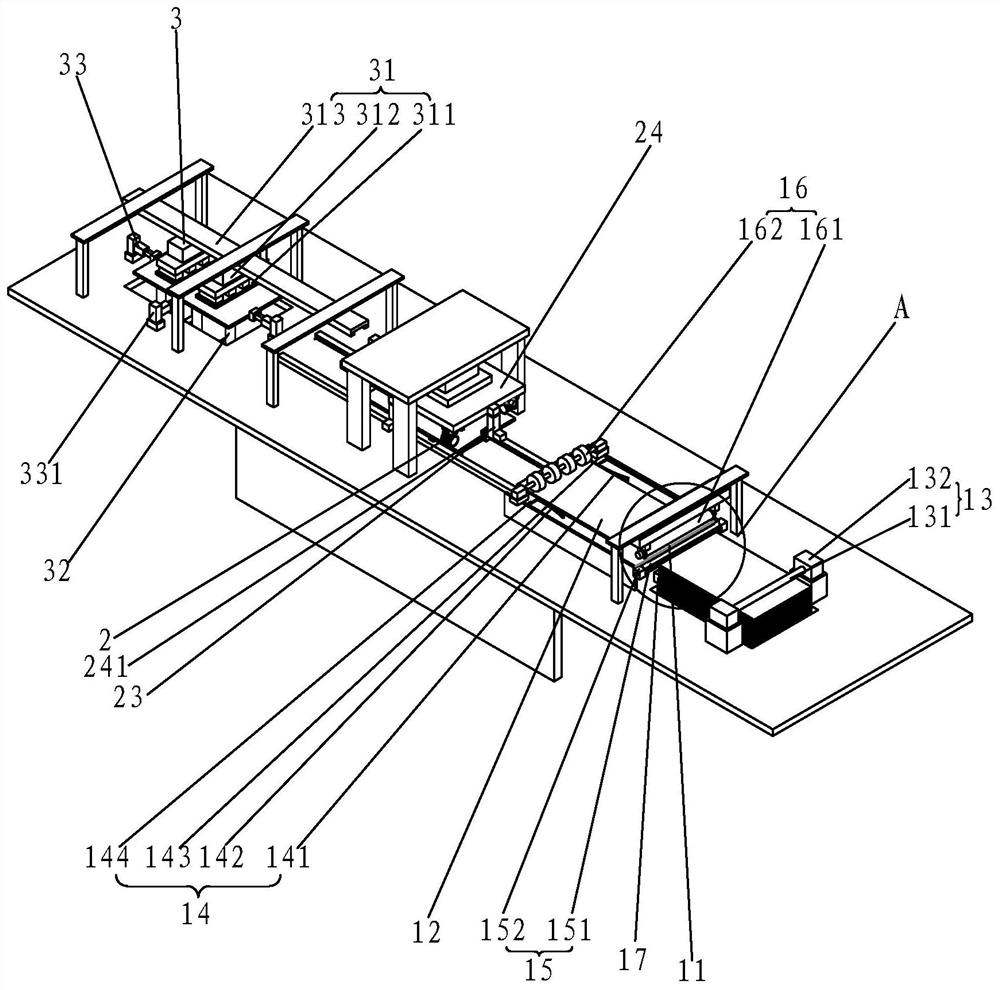

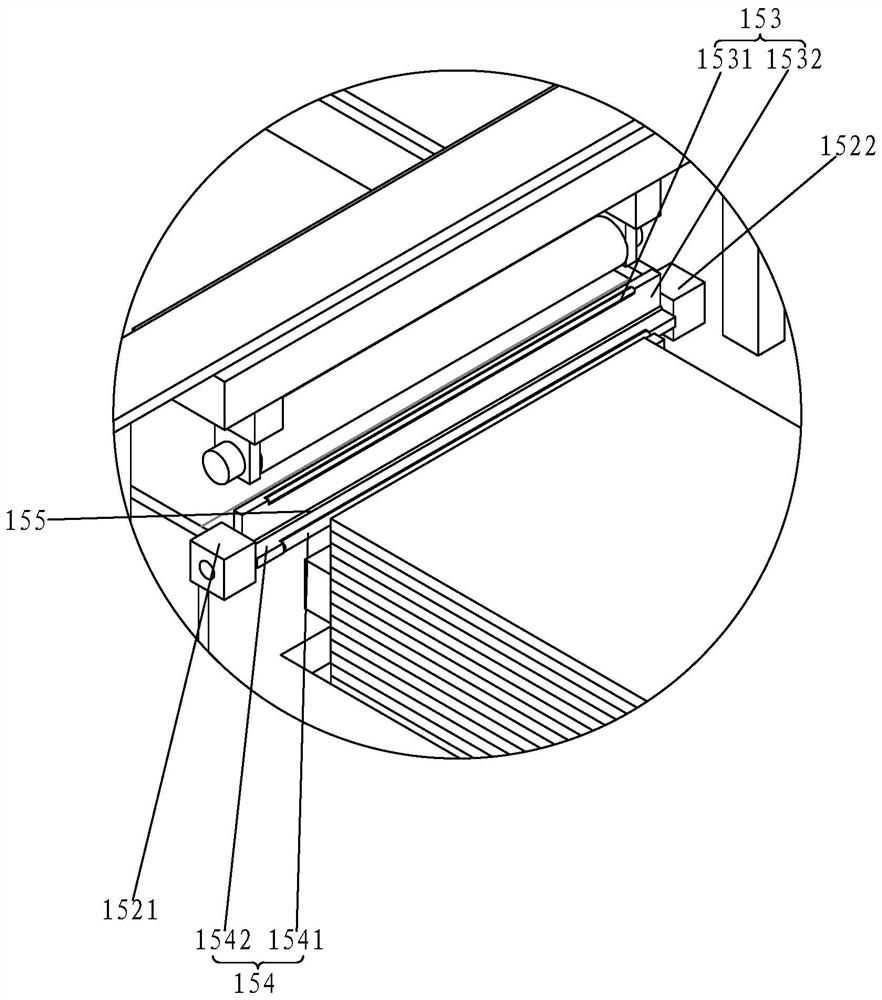

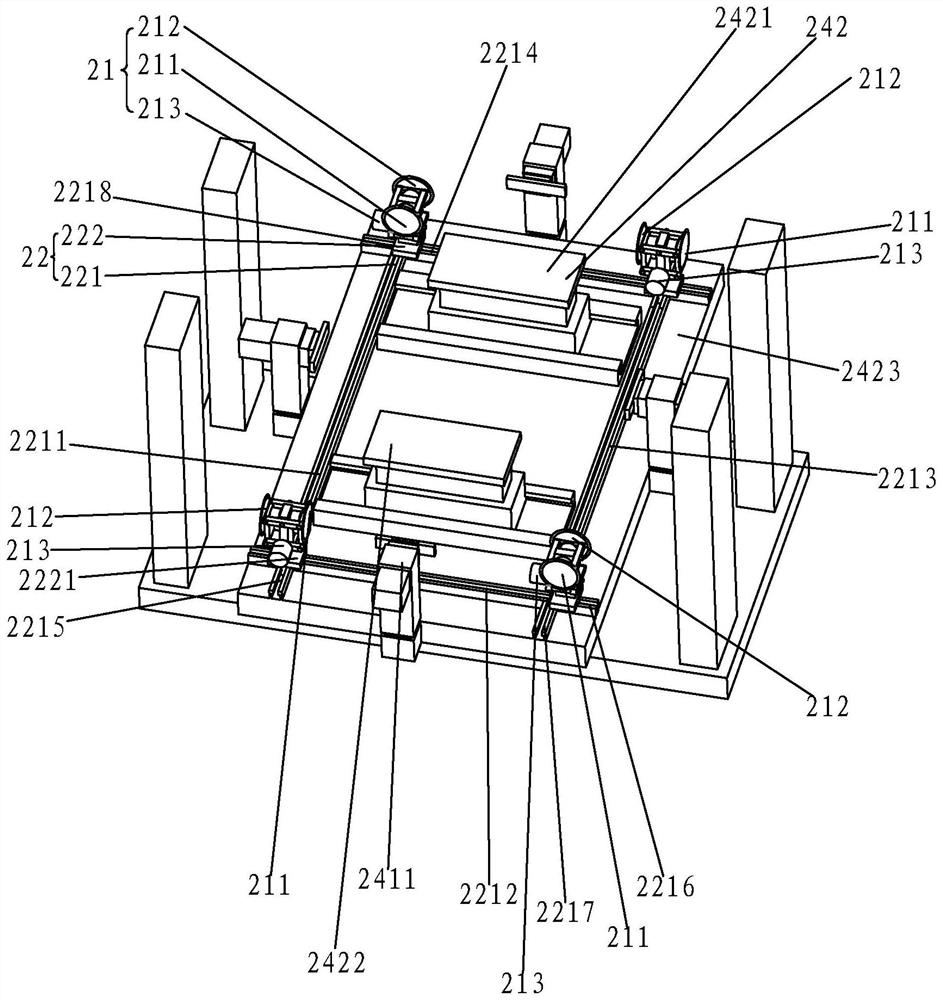

[0059] Such as Figure 1 to Figure 4 As shown, an unmanned and waste-free digital complete production line for rectangular plates of the present invention includes a feeding device 1 for supplying rectangular plates to be processed; feeding device 1 includes a carrying platform for carrying multiple rectangular plates, and for the The conveying mechanism 11 that the rectangular plate is conveyed; The conveying mechanism 11 includes the conveying device 12 that the rectangular plate is conveyed, the feeding device 13 that conveys the rectangular plate to the conveying device 12, and the adjusting device 14 that adjusts the position of the rectangular plate; the adjusting device 14 is located above the conveying device 12 .

[0060] In this way, the output of the rectangular plate to the edge sawing device 2 by the feeding device 1 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com