Precise inner hexagon machining lathe for valve element of pressure valve and machining process of precise inner hexagon machining lathe

A pressure valve and angle processing technology, applied to the processing field of inner hexagon, can solve the problems of inconvenience for users to use, the accuracy of inner hexagon can not meet the actual use requirements, etc., to save time, reduce flow, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

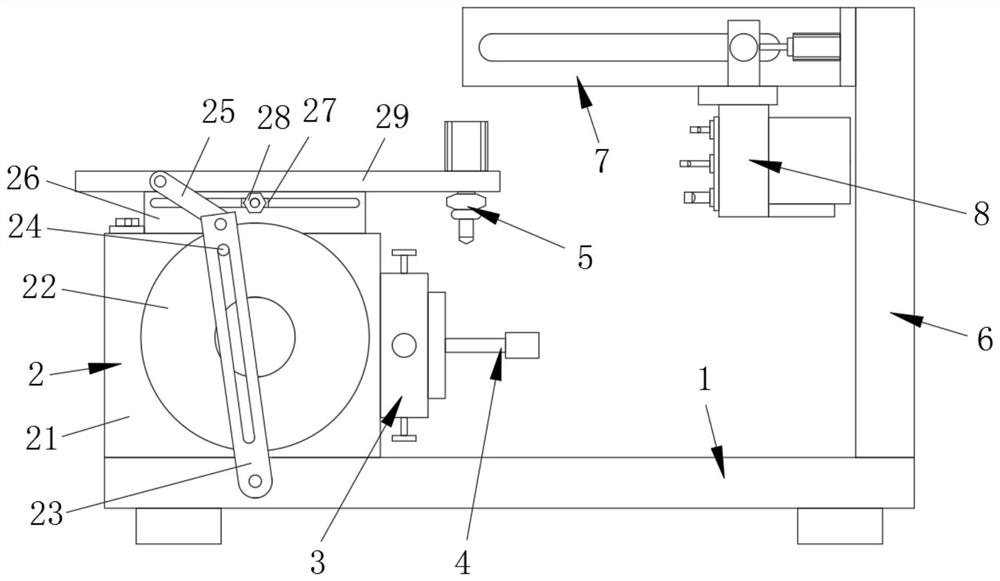

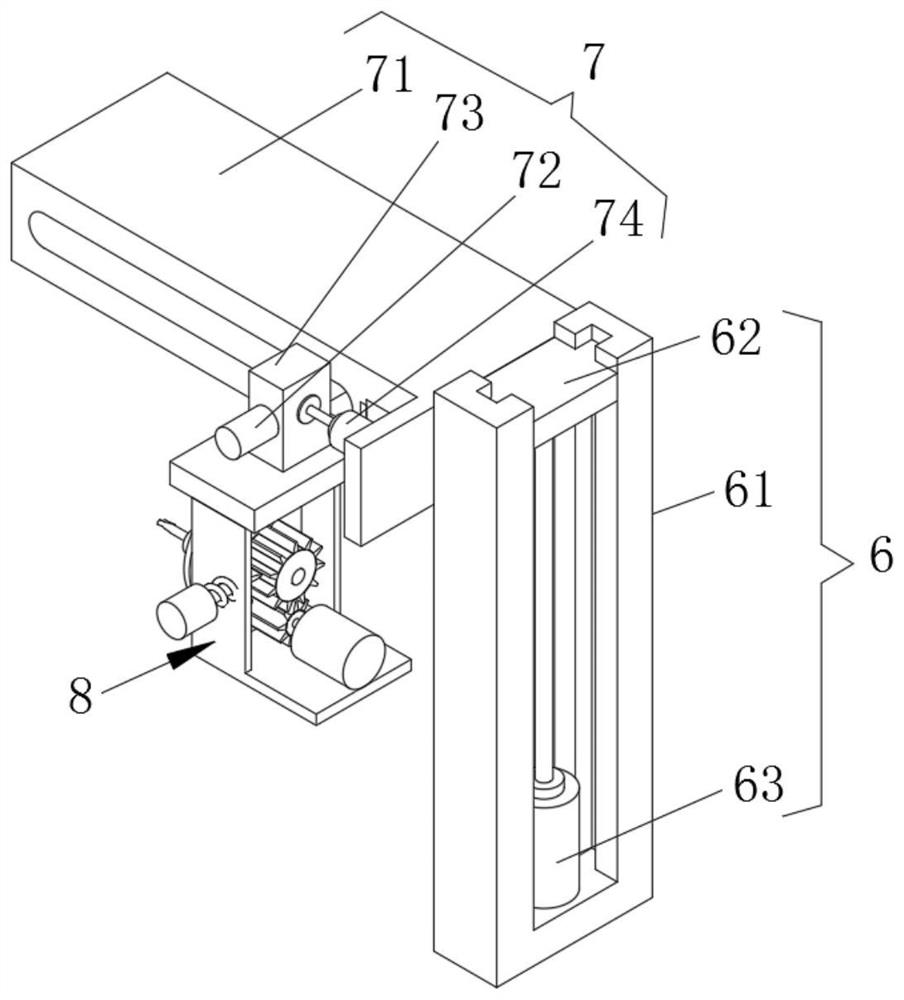

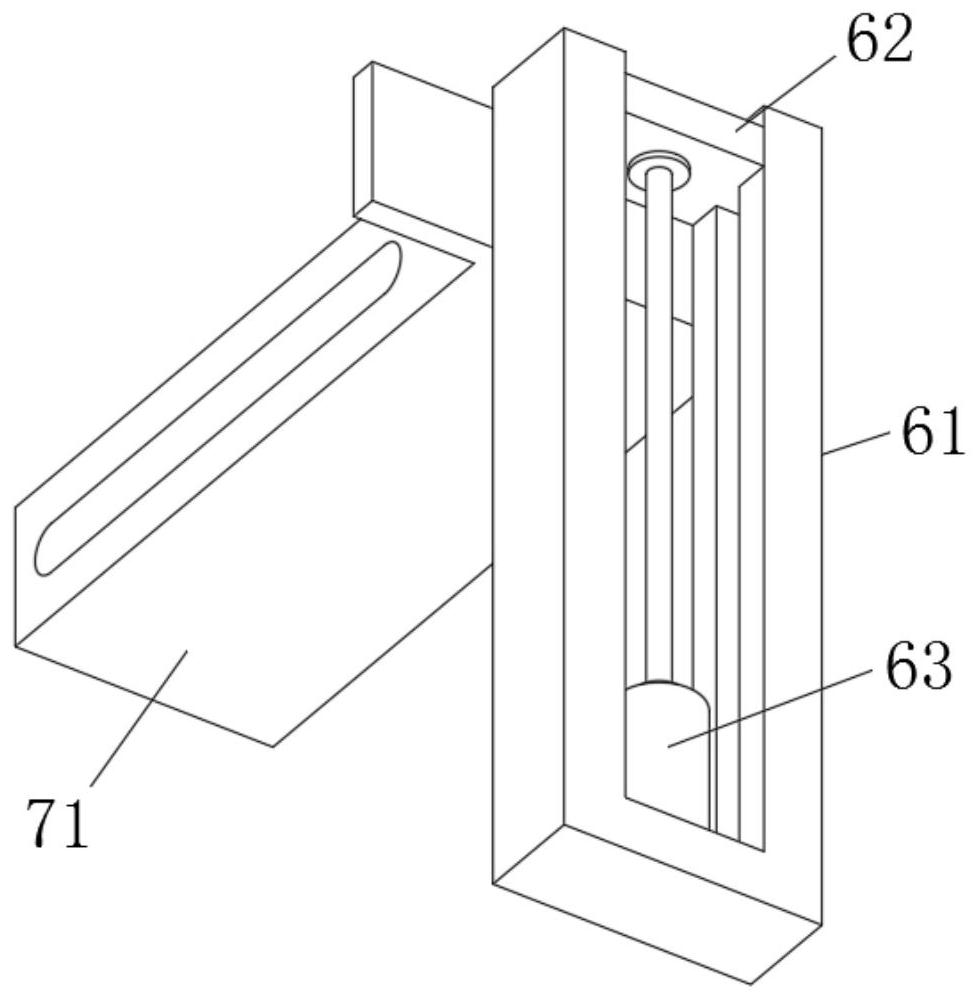

[0034] see Figure 1-5, the present invention provides a technical solution, a pressure valve spool precision inner hexagon processing lathe, including an equipment base 1, a moving device 2 is provided on the left side of the top of the equipment base 1, and a height adjustment is provided on the right side of the top of the equipment base 1 Mechanism 6, the top on the left side of the height adjustment mechanism 6 is provided with a lateral movement mechanism 7, the bottom of the lateral movement mechanism 7 is provided with a pull pin cutter adjustment mechanism 8, and the right side of the mobile device 2 top is embedded with a cutting device 5, in practice When in use, the user can operate the moving device 2 to push the cutting device 5 to move to the right or left, so as to process the surface of the inner hexagonal workpiece 4, which is convenient for the user to process the surface of the inner hexagonal workpiece 4 into a desired appearance. The right side of the mov...

Embodiment 2

[0045] see Figure 1-5 , the present invention provides a technical solution, a pressure valve spool precision inner hexagon processing lathe, including an equipment base 1, a moving device 2 is provided on the left side of the top of the equipment base 1, and a height adjustment is provided on the right side of the top of the equipment base 1 Mechanism 6, the top on the left side of the height adjustment mechanism 6 is provided with a lateral movement mechanism 7, the bottom of the lateral movement mechanism 7 is provided with a pull pin cutter adjustment mechanism 8, and the right side of the mobile device 2 top is embedded with a cutting device 5, in practice When in use, the user can operate the moving device 2 to push the cutting device 5 to move to the right or left, so as to process the surface of the inner hexagonal workpiece 4, which is convenient for the user to process the surface of the inner hexagonal workpiece 4 into a desired appearance. The right side of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com