Special fixture for milling inclined planes of symmetric V-shaped parts with holes

A special fixture and bevel milling technology, used in metal processing mechanical parts, clamping, manufacturing tools, etc., can solve the problems of difficult alignment, inaccurate positioning, and high processing costs, shortening processing time, clamping and positioning. Simple and efficient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

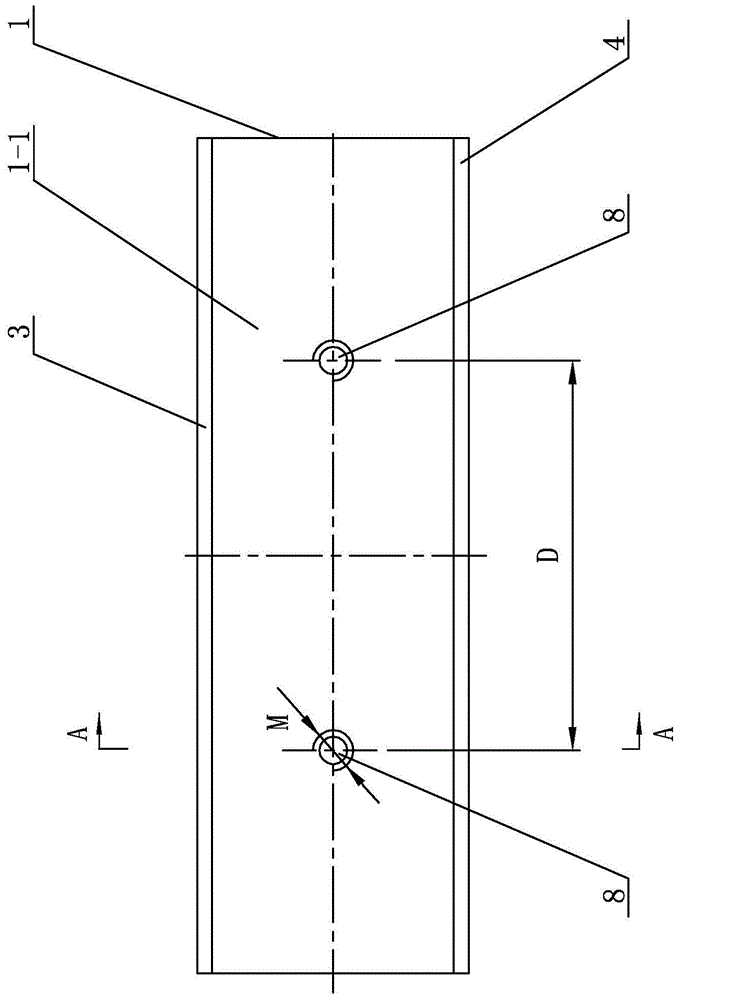

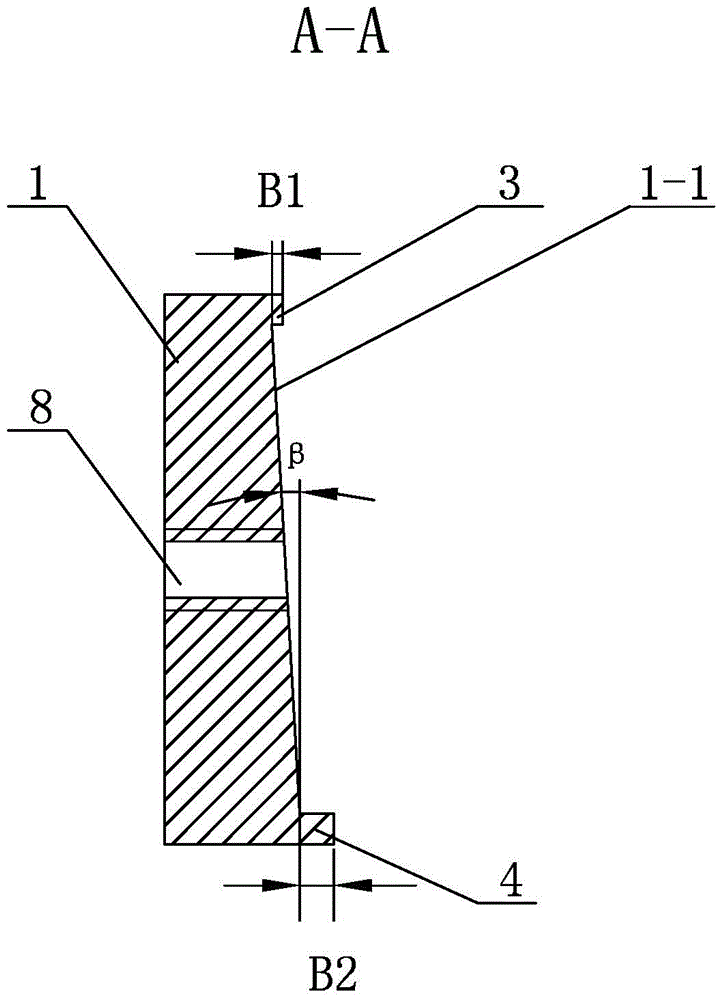

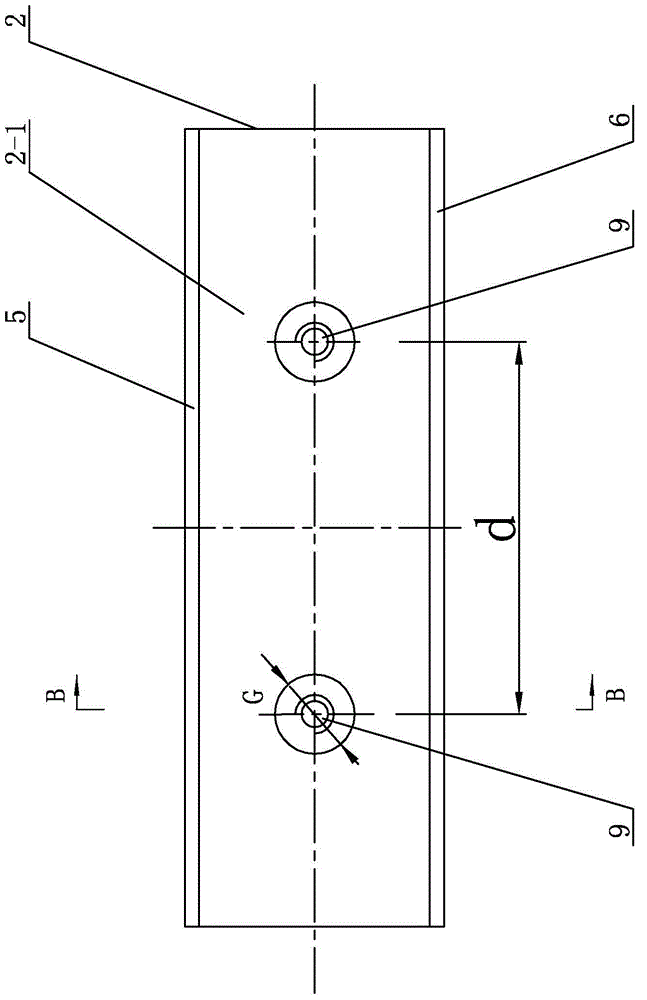

[0013] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 This embodiment is described. The special fixture for milling and beveling of symmetrical V-shaped parts with holes described in this embodiment includes a first clamp body 1, a second clamp body 2, a first retaining edge 3, a second retaining edge 4, and a second retaining edge. Three retaining ribs 5, the fourth retaining rib 6 and two screws 7, the first clamping body 1 and the second clamping body 2 are rectangular, and one end surface of the first clamping body 1 is the first inclined surface 1- 1. Both the first retaining edge 3 and the second retaining edge 4 are located on the first inclined surface 1-1, the first retaining edge 3 is fixedly connected above the first inclined surface 1-1, and the second retaining edge 4 is fixed Connected below the first inclined surface 1-1, two through holes 8...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 To describe this embodiment, the two screws 7 in this embodiment are all hexagon socket head cap screws. This type of screw has the best connection effect in actual work. The two screws 7 are used repeatedly twice during the machining process, just for accurate machining accuracy of the two slopes of the symmetrical V-shaped holed part 10 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 To describe this embodiment, in this embodiment, the center of each through hole 8 is located on the center line in the longitudinal direction of the first inclined surface 1 - 1 . The two through holes 8 arranged at this position make the connection effect between the first clamp body 1 and the symmetrical V-shaped holed part 10 good, and the precision of both sides of the processed symmetrical V-shaped holed part 10 is higher. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com