Method for preparing stable compound through gas-liquid plasma technology and application of method

A plasma and composite technology, applied in the fields of botanical equipment and methods, applications, nanotechnology, etc., can solve the problems of unstable surfactants and performance degradation, and achieve cost savings, small footprint, and reaction energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

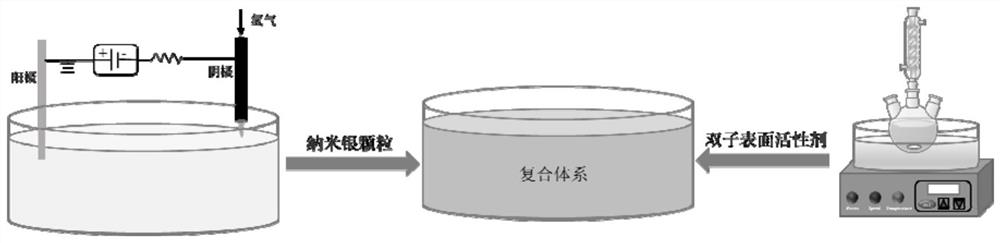

[0034] A method for preparing a stable compound by gas-liquid plasma technology, said method comprising the steps of:

[0035] (1) 10mL of 0.1mM silver nitrate aqueous solution and 3mL of 1% PVA aqueous solution are mixed, and the mixed solution is used as the reaction solution;

[0036] (2) The reaction solution obtained in step (1) is placed in a petri dish, and the petri dish is placed at 3 mm below the stainless steel tube cathode (tube length 60 mm, tube inner diameter 1.6 mm, tube outer diameter 1.8 mm) of the plasma reactor, A platinum wire is inserted into the reaction solution as an anode;

[0037] (3) In the plasma reactor, the argon gas of 30 sccm is regulated and controlled by the mass flow control meter and passed into the plasma reactor, and maintained for 3min, and then under the argon atmosphere, a DC negative bias is applied to the cathode of the plasma reactor to ensure that the output power is 10W is used to break down the argon gas to generate plasma. Afte...

Embodiment 2

[0043] The preparation method is the same as in Example 1, except that the precursor is 0.3 mM silver nitrate solution.

Embodiment 3

[0045] The preparation method is the same as in Example 1, except that the precursor is a 0.5 mM silver nitrate solution.

[0046] The ultraviolet absorption spectrum figure of the colloidal solution containing silver nanoparticles prepared under different concentrations of precursors in embodiment 1-3 is as follows Figure 6 shown by Figure 6It can be seen that under the same plasma treatment conditions, the number of silver nanoparticles in the solution increases with the increase of the concentration of silver nitrate, so the corresponding surface plasmon resonance absorption peak also increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Tube inner diameter | aaaaa | aaaaa |

| Tube outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com