Unmanned aerial vehicle intelligent spraying system

An unmanned aerial vehicle and intelligent technology, applied in the direction of spraying devices, etc., can solve the problems of high labor intensity, poor adaptability to complex curved surfaces, and low degree of intelligence of the staff, so as to improve battery life, realize optimization, and improve spraying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

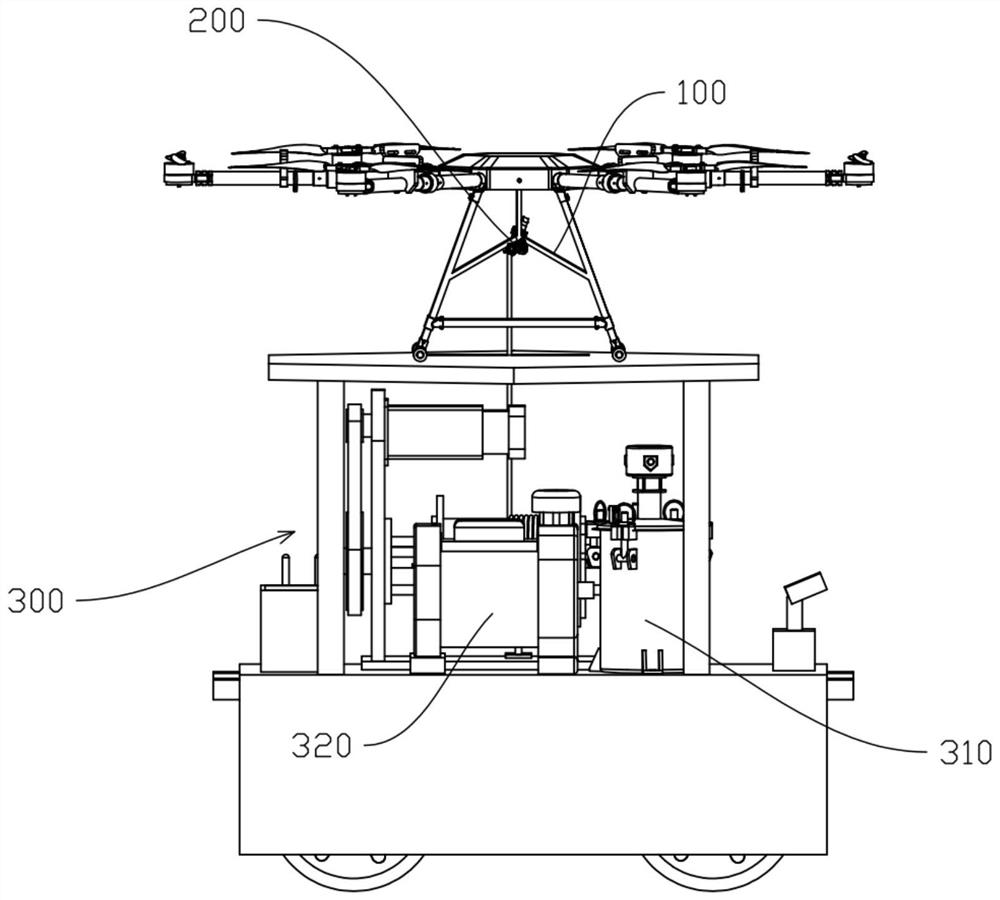

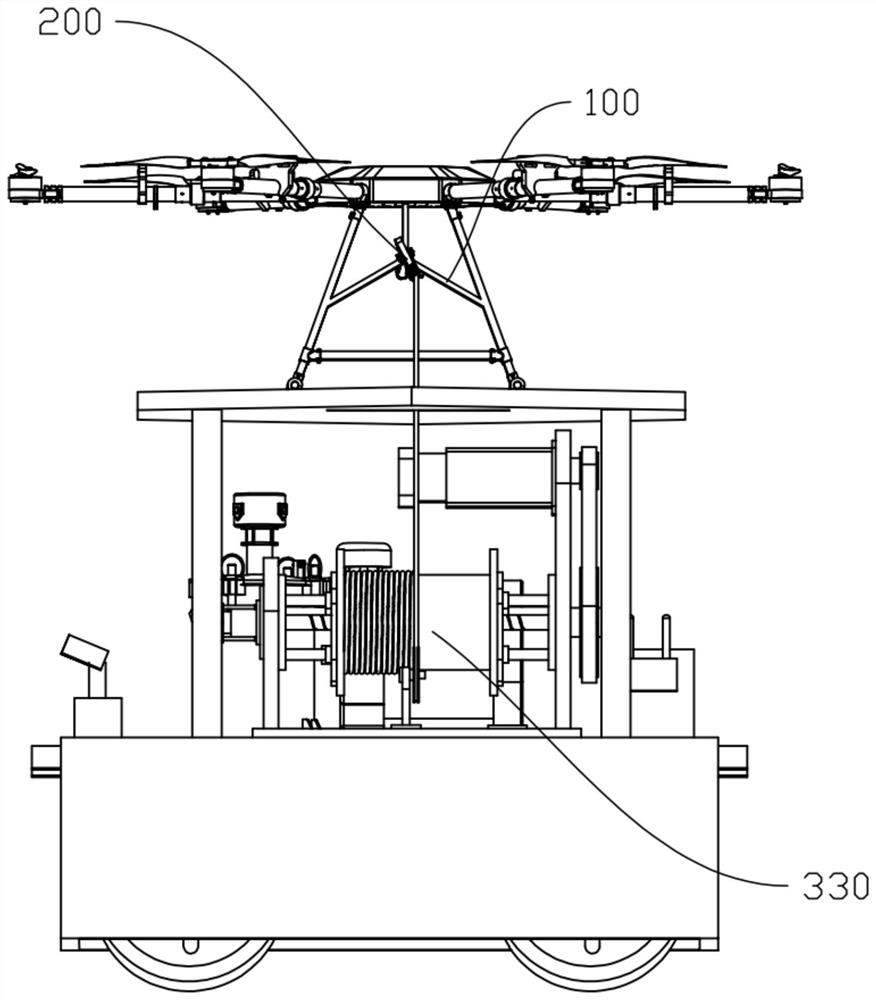

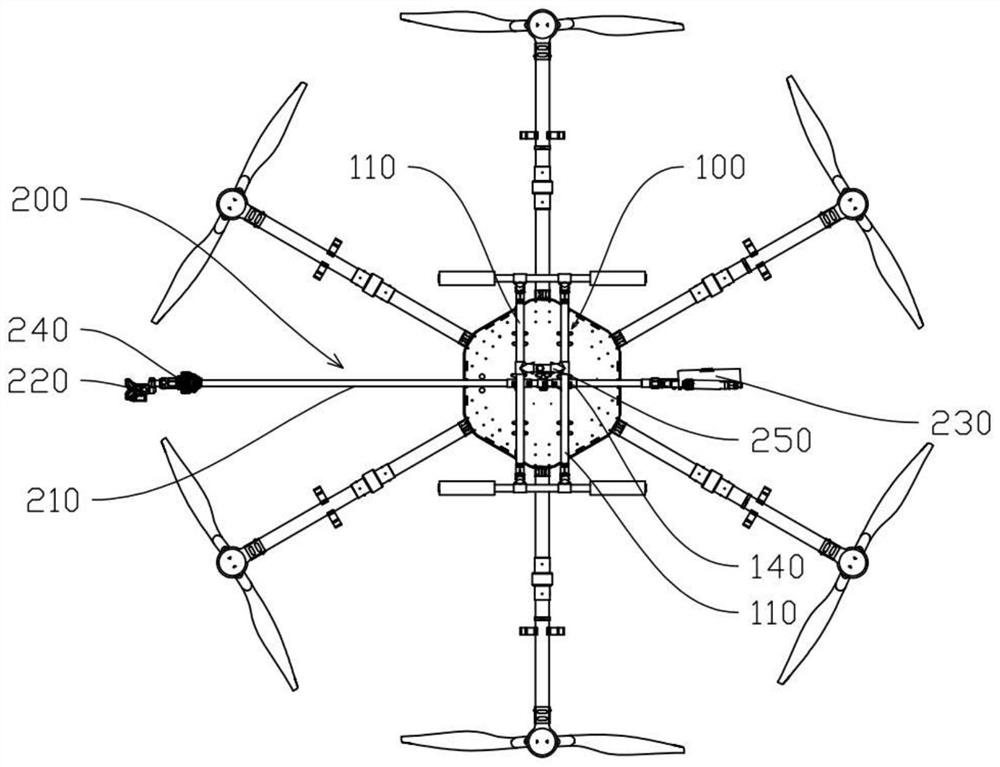

[0027] refer to figure 1 and figure 2 According to the embodiment of the invention, the UAV intelligent spraying system includes a UAV, a follower car, a Y-shaped support assembly 100, a spraying assembly 200, a material conveying assembly 300, a dynamic joint control system and a ground station. Among them, the Y-shaped support assembly 100 is detachably arranged at the lower end of the drone, the spraying assembly 200 is detachably installed at the center of the Y-shaped support assembly 100, the material delivery assembly 300 is arranged on the follower trolley, and the material delivery assembly 300 It is connected with the spraying assembly 200 through a delivery pipe. The dynamic joint control system is used to control the power output and pipeline retraction of the UAV and the follow-up car. The ground station communicates with the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com