A device for controlling liquid jet crushing

A technology of liquid jet and controller, applied in the direction of jetting device, etc., can solve the problems of inability to implement concretely, without specific disclosure of implementation scheme, device and principle, etc., and achieve the effect of good focusing effect, saving space, and improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

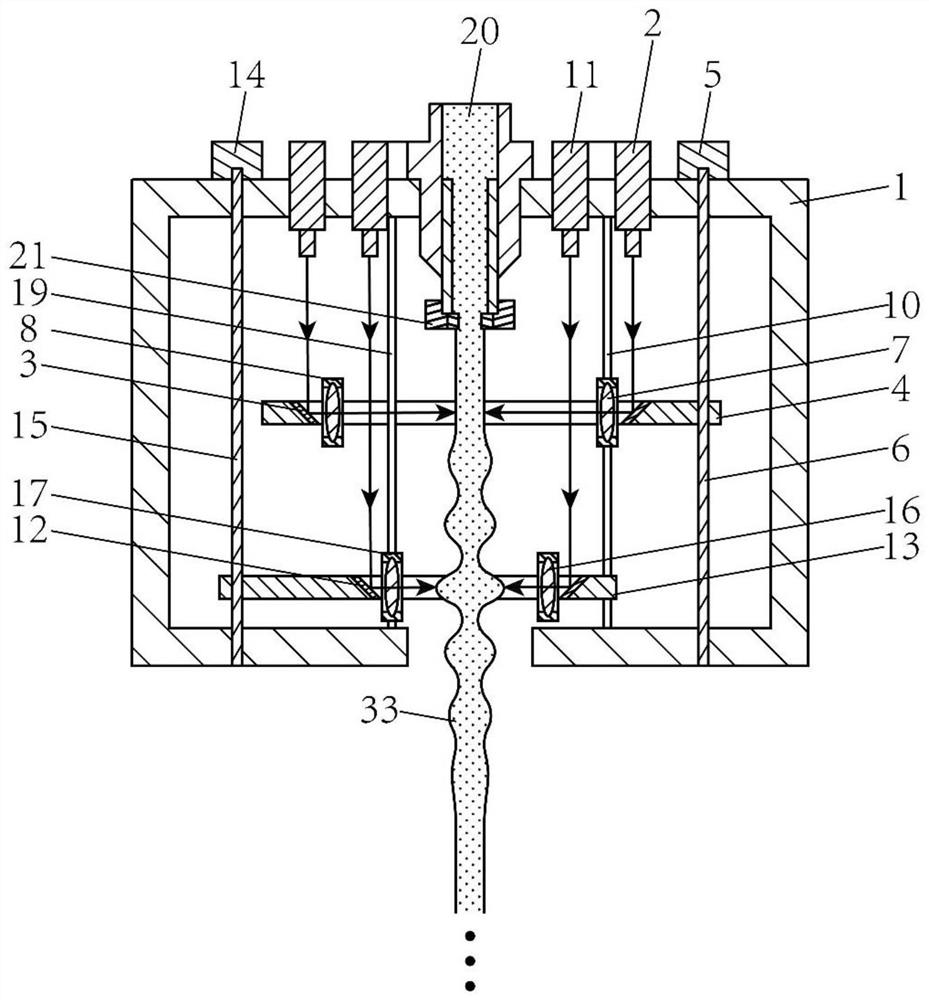

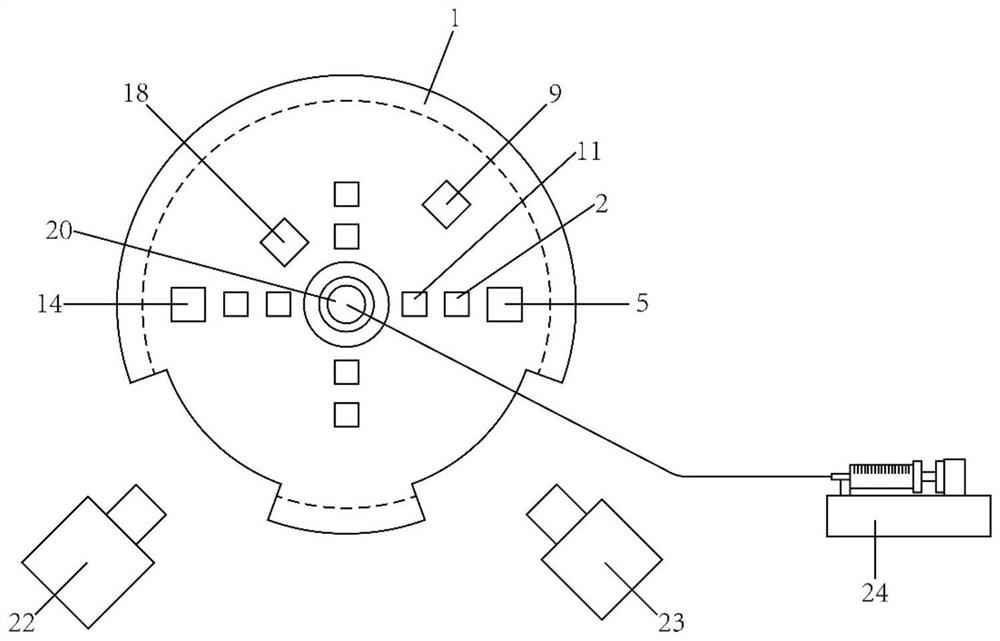

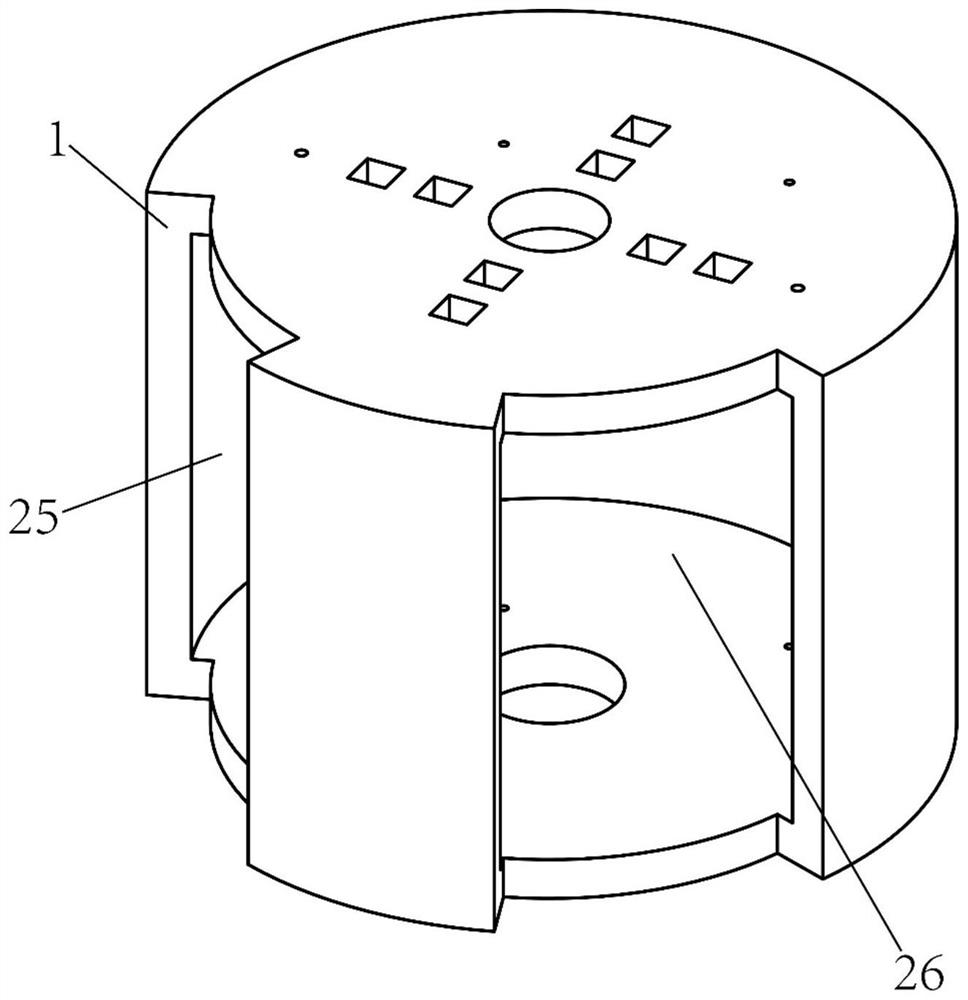

[0022] The device for controlling liquid jet fragmentation proposed by the present invention has a structure such as figure 1 and figure 2 As shown, it includes a cavity 1 that plays an overall supporting role for the structure of the device, an outer pulse laser focusing heating system inside the cavity 1, an inner pulse laser focusing heating system, and a measurement system outside the cavity 1;

[0023] The outer layer pulse laser focusing heating system includes an outer layer pulse laser group 2, an upper layer reflector 3, an upper layer reflector mounting frame 4, a first rotation controller 5, an upper layer reflector screw rod 6, an upper layer convex lens 7, and an upper layer convex lens Mounting frame 8, second rotation controller 9, upper layer convex lens screw mandrel 10; Outer layer pulse laser group 2 is installed on the top of cavity 1 evenly along the circumference, in one embodiment of the present invention, outer layer pulse laser group 2 Contains 4 set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com