Chemical feeding equipment

A kind of equipment and chemical technology, applied in the field of chemical powder feeding, which can solve the problems of crushing materials that cannot be agglomerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

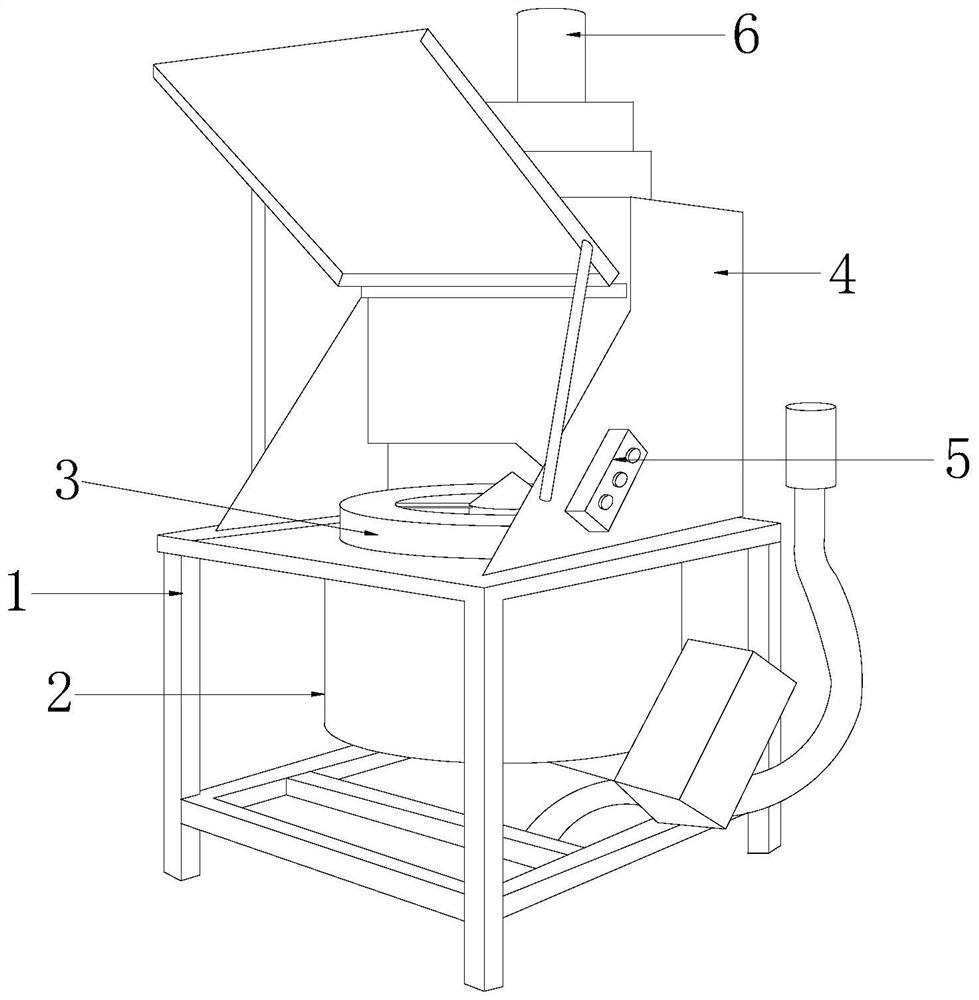

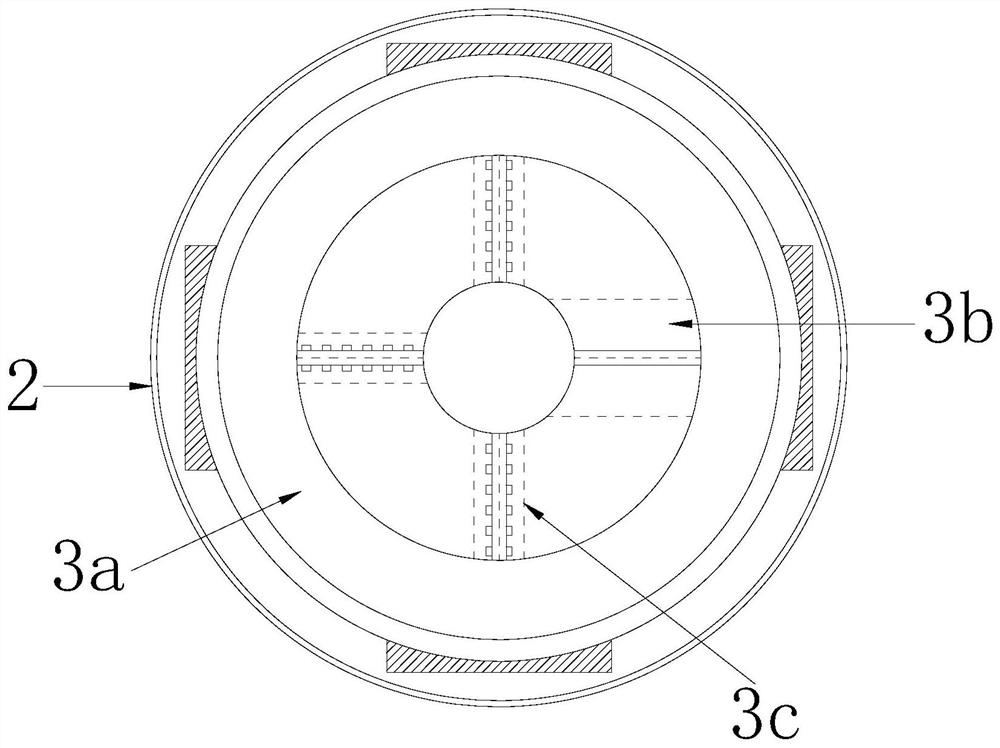

[0030] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of technical scheme of chemical industry feeding equipment:

[0031] Such as Figure 1-Figure 2 As shown, a chemical feeding equipment, its structure includes a bracket 1, a vibrating screen drum 2, a circumflex crushing device 3, a feeding rack 4, a controller 5, and a drive motor 6, and the vibrating screen drum 2 is installed inside the bracket 1, The circumflex crushing device 3 is arranged on the upper surface of the vibrating screen cylinder 2, the feeding rack 4 is installed on the upper surface of the bracket 1, the controller 5 is arranged on the right side surface of the feeding rack 4, and the driving motor 6 is arranged on the feeding rack 4. On the upper surface of the frame 4, the circumflex crushing device 3 includes a sub-injection structure 3a, a crushing mechanism 3b, and a sieve structure 3c. The sub-injection structure 3a is installed on the upper surface of the vibrating scr...

no. 2 example

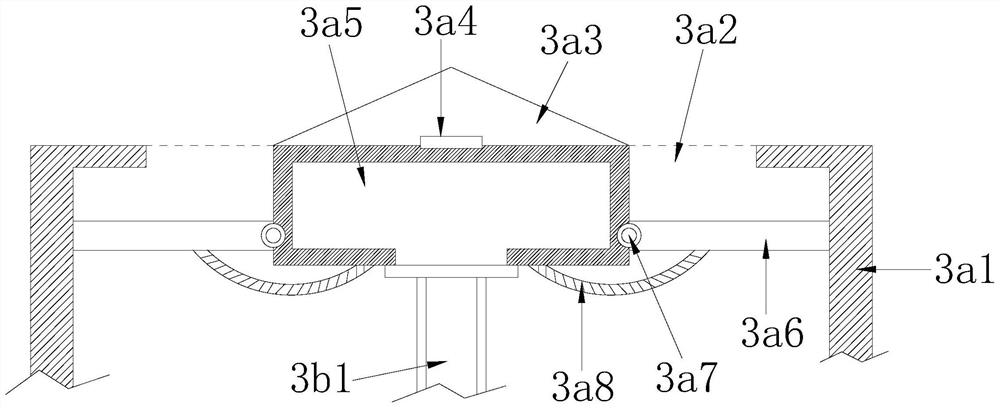

[0039] Such as Figure 4-Figure 7 As shown, the present invention provides a kind of technical scheme of chemical industry feeding equipment:

[0040] Such as Figure 4-Figure 5 As shown, a chemical feeding equipment, its structure includes the rolling mechanism 3b including a connecting pipe 3b1, a fixed frame plate 3b2, an overflow layer 3b3, and an extruding rod 3b4, and the connecting pipe 3b1 is arranged on the lower surface of the cavity frame 3a5 And through the connection, the fixed frame plate 3b2 is horizontally installed on the lower surface of the connecting pipe 3b1 and connected through the connection, the overflow layer 3b3 is provided on the lower surface of the fixed frame plate 3b2 and is an integrated structure, the matching There are more than eight rods 3b4 and they are installed on the lower surface of the fixed frame plate 3b2 in a uniform and equidistant shape, which is beneficial to realize the cooperation with the sieve structure 3c, squeeze the aggl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com