Method for solubilizing hydrophobic polyphenol with hydrophilic polyphenols

A hydrophilic and hydrophobic technology, applied in the direction of pharmaceutical formulations, organic active ingredients, food ingredients, etc., can solve problems such as difficult large-scale preparation, difficult control of product quality, immature large-scale preparation technology, etc., to achieve a solution It is difficult to control the quality, improve the water solubility of HPs, solubilize and protect the effect of HPs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

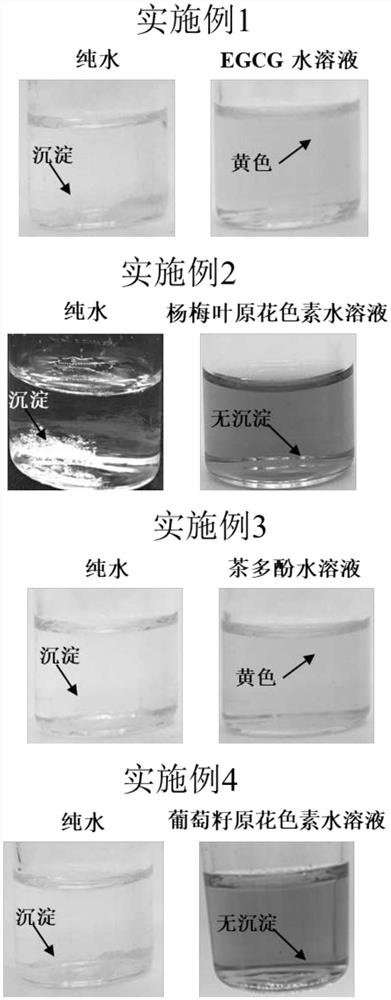

Embodiment 1

[0033] Weigh 1g of epigallocatechin gallate (EGCG) with a purity of 98% and place it in a 2L container, add 800mL of pure water, stir well, heat up to 35°C, continue stirring until EGCG dissolves, add pure water and make up to 1L , made EGCG solution.

[0034] Weigh 50 mg of curcumin with a purity of 98% and place it in a 50 mL container, add 18 mL of pure ethanol and stir to dissolve, and set the volume to 20 mL to prepare a curcumin solution.

[0035] The above-mentioned 20 mL of curcumin solution was slowly added to 1 L of EGCG solution, and at the same time, the solution was stirred at 200 rpm for uniform mixing, and allowed to stand for 10 minutes to obtain a stable curcumin aqueous solution.

[0036] Pure water was used as a control, that is, an ethanol solution (20 mL) containing 50 mg of curcumin was added to 1 L of pure water, stirred uniformly, and then allowed to stand for 10 minutes.

Embodiment 2

[0038] Weigh 2.5g of bayberry leaf proanthocyanidins with a purity of 85% and place it in a 2L container, add 800mL of pure water, stir evenly, heat up to 35°C, continue to stir until dissolved, filter to remove insoluble impurities, add pure water to make up to 1L, A solution of bayberry leaf proanthocyanidins was prepared.

[0039] Weigh 100 mg of hesperidin with a purity of 98% and place it in a 50 mL container, add 8 mL of dimethylformamide, stir to dissolve, and set the volume to 10 mL to prepare a hesperidin solution.

[0040] The above-mentioned 10 mL of hesperidin solution was slowly added to 1 L of the aqueous solution of bayberry leaf proanthocyanidins, and at the same time stirred at 300 rpm for uniform mixing, and allowed to stand for 10 minutes to obtain a stable aqueous solution of hesperidin.

[0041] Pure water was used as a control, that is, a dimethylformamide solution (10 mL) containing 100 mg of hesperidin was added to 1 L of pure water, stirred uniformly, ...

Embodiment 3

[0043] Weigh 2.0g of tea polyphenols with a purity of 95% and place it in a 2L container, add 800mL of pure water, stir evenly, heat up to 35°C, continue to stir until dissolved, filter to remove insoluble impurities, add pure water to make up to 1L, and make Tea polyphenol solution.

[0044] Weigh 200 mg of 95% turmeric extract in a 50 mL container, add 18 mL of pure ethanol, stir to dissolve, filter to remove insoluble impurities, and set the volume to 20 mL to prepare a turmeric extract solution.

[0045] Slowly add 20 mL of turmeric extract solution to 1 L of tea polyphenol solution, stir and mix at 200 rpm at the same time, and let stand for 10 minutes to obtain a stable aqueous solution of turmeric extract.

[0046] Pure water was used as a control, that is, an ethanol solution (20 mL) containing 200 mg of curcumin extract was added to 1 L of pure water, stirred uniformly, and then allowed to stand for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com