Heat-proof sleeve as well as preparation method and forming device thereof

A heat-resistant sleeve and ablation-resistant technology, which is applied in the field of composite materials, can solve the problems of poor ablation resistance and poor flexibility of FRP heat-resistant sleeves, and achieve good flexibility, reduced size ablation, and good ablation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

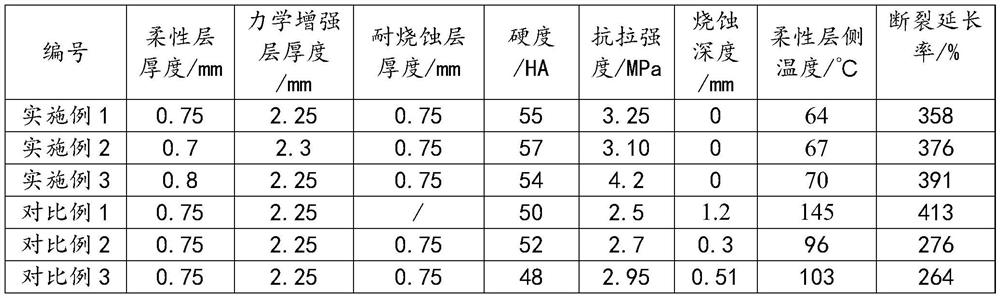

Examples

Embodiment 1

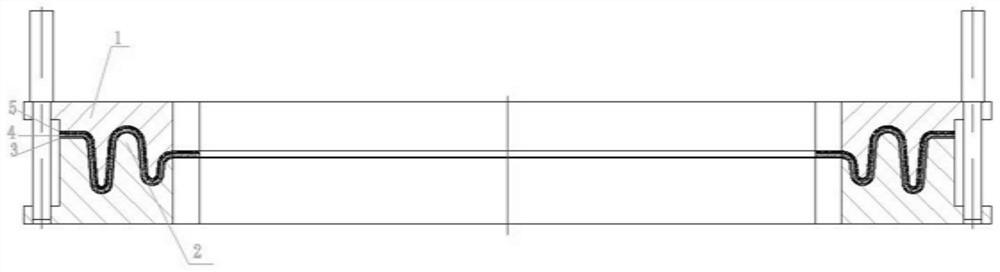

[0047] Embodiment 1 provides a kind of preparation method of heat shield, specifically as follows:

[0048] 1. Spray release agent:

[0049] Spray the film coating agent on the surface of the upper mold 2 and the surface of the lower mold 3 with a low-pressure spray gun, the number of times of spraying is 2 times, the interval time is 15min, and the spraying amount of the upper mold is 50g / m 2 , the total amount of spraying on the lower mold is 50g / m 2 .

[0050] 2. Layer:

[0051] Lay silicone rubber, quartz glass fiber reinforced silicone rubber, and zirconium boride particles with a particle size of ≤1 μm mixed with silicone rubber on the surface of the cavity of the lower mold 3 in sequence, and each layer is overlapped. The strength is staggered to form a heat-resistant layer 4 , a mechanically enhanced layer 5 and an ablation-resistant layer 6 .

[0052] 3. Mold closing:

[0053] Upper mold 2 and lower mold 3 are clamped.

[0054] 4. Vulcanization:

[0055] The cu...

Embodiment 2

[0059] Embodiment 2 provides a kind of preparation method of heat shield, specifically as follows:

[0060] 1. Spray release agent:

[0061] Use a low-pressure spray gun to spray the coating agent on the surface of the upper mold 2 and the surface of the lower mold 3, the number of sprays is 3 times, the interval is 16min, and the total spraying amount of the upper mold is 50g / m 2 , the total amount of spraying on the lower mold is 50g / m 2 .

[0062] 2. Layer:

[0063] Lay silicone rubber, quartz glass fiber reinforced glue, and zirconia particles with a particle size of ≤1 μm mixed with silicone rubber on the surface of the cavity of the lower mold 3 in sequence, and each layer is overlapped. The overlap width is 80mm, and the overlap strength between layers is staggered. , forming a heat-resistant layer 4 , a mechanically enhanced layer 5 and an ablation-resistant layer 6 .

[0064] 3. Mold closing:

[0065] Upper mold 2 and lower mold 3 are clamped.

[0066] 4. Vulcan...

Embodiment 3

[0071] Embodiment 3 provides a kind of preparation method of heat shield, specifically as follows:

[0072] 1. Spray release agent:

[0073] Spray the film coating agent on the surface of the upper mold 2 and the surface of the lower mold 3 with a low-pressure spray gun, the number of times of spraying is 3 times, the interval time is 16min, and the spraying amount of the upper mold is 45g / m 2 , the total amount of spraying on the lower mold is 45g / m 2 .

[0074] 2. Layer:

[0075] Lay silicone rubber, quartz glass fiber reinforced glue, zirconium boride particles with a particle size of ≤1 μm, and zirconia particles mixed with silicone rubber on the surface of the cavity of the lower mold 3 in sequence, and each layer is overlapped, and the overlap width is 80mm. The overlapping strength between layers is staggered to form a heat-resistant layer 4 , a mechanically enhanced layer 5 and an ablation-resistant layer 6 . Wherein, the mass ratio of zirconium boride particles to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com