A new threaded metal bellows joint and its construction method

A metal bellows and screw-shaped technology, which is applied in the direction of buildings, building reinforcements, building components, etc., can solve problems affecting the quality of prestressed construction, blockage of prestressed pipes, and leakage of grout, so as to achieve reliable connection, reliability and The effect of effective sealing connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

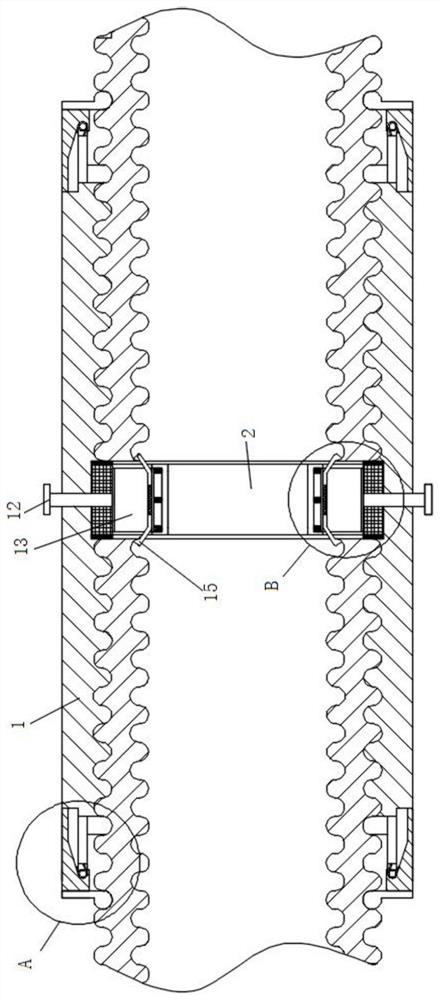

[0033] Such as Figure 1 to Figure 5 As shown, a brand-new threaded metal bellows joint includes a connecting pipe body 1 that is threadedly matched with the bellows, and a fixed ring 2 is fixed inside the connecting pipe body 1, and two Both sides are provided with seals 3 . The positioning ring 2 is used to control the connection length and the sealing member 3 realizes a reliable and effective sealing connection effect for the corrugated pipe to be connected, and realizes the effect that the connecting pipe body 1 and the corrugated pipe are not easy to fall off after being connected.

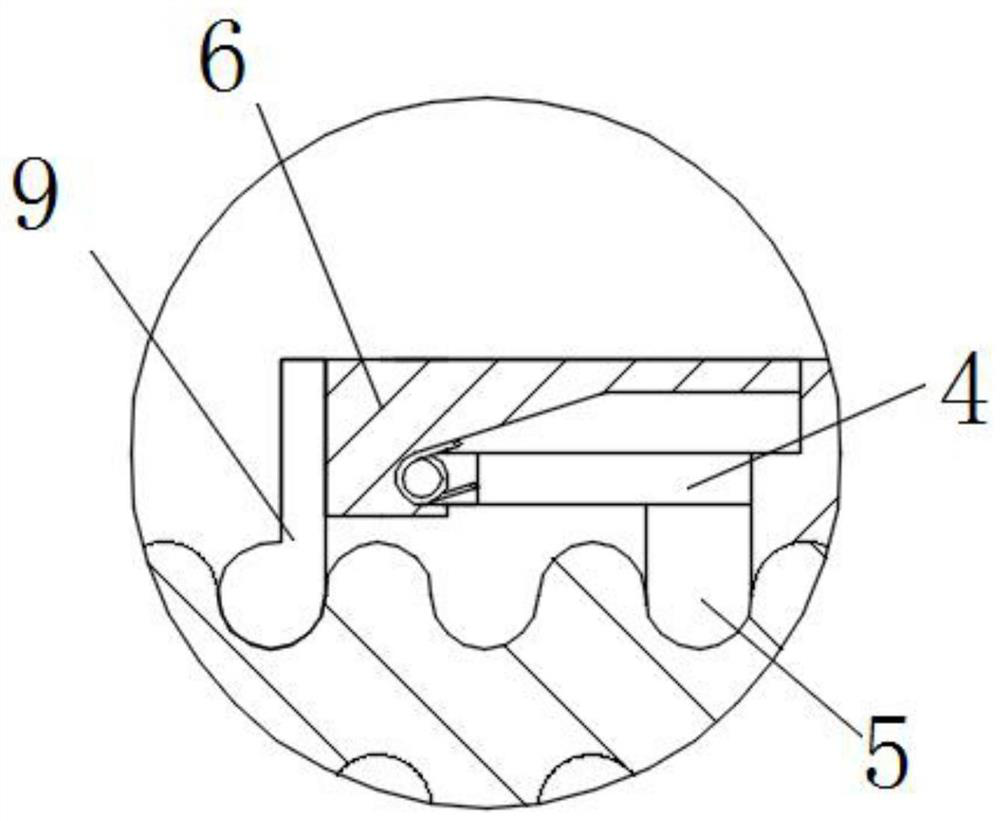

[0034] In a further preferred solution of this embodiment, both ends of the connecting pipe body 1 are provided with an anti-disengagement assembly, and the anti-disengagement assembly includes a fixing piece 6 fixedly installed at the end of the connecting pipe body 1 and a rotatably connected fixing piece 6 The inner anti-off piece 4 is provided with a torsion spring at the rotational con...

Embodiment 2

[0042] A construction method for a brand-new threaded metal bellows joint, comprising the following steps:

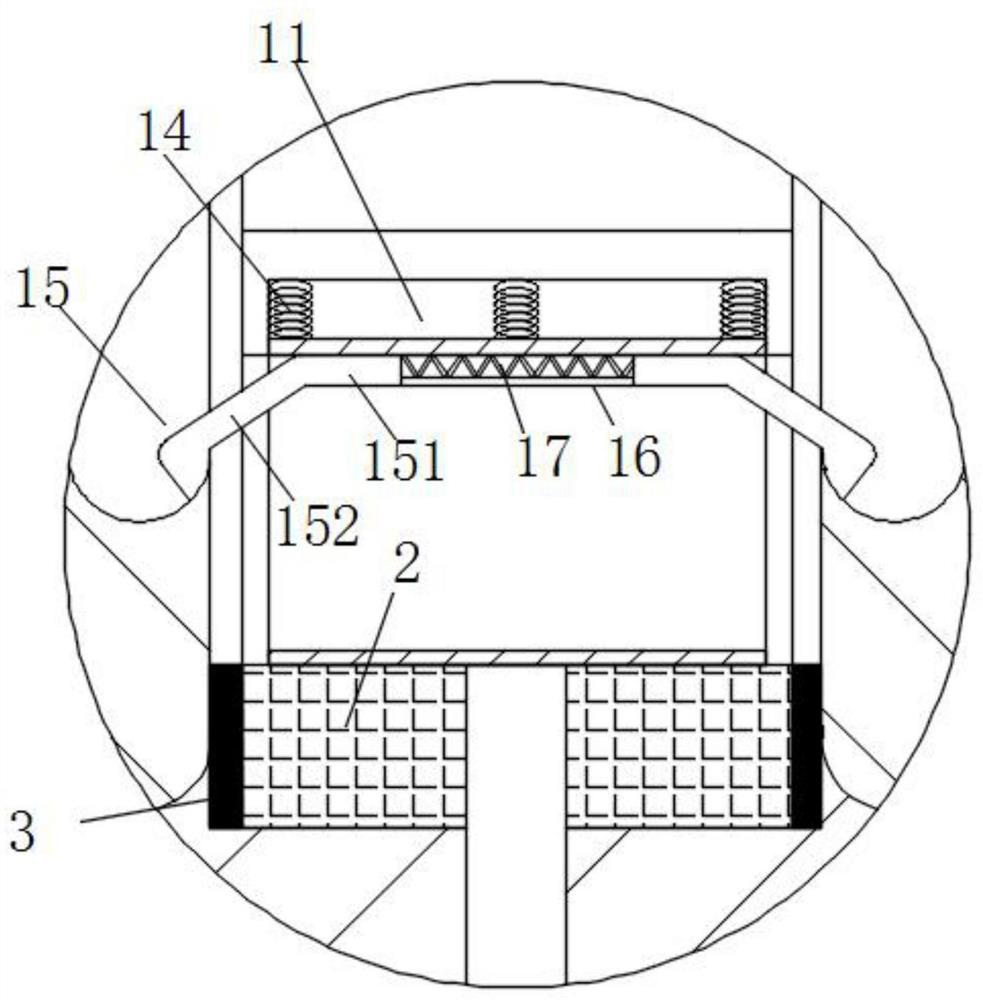

[0043] A. First, adjust the adjusting member 12 to push the fixed frame 13 to move along the guide channel 11 to the side close to the central axis of the connecting pipe body 1. During the process, the clamping part 152 of the clamp claw 15 will be affected by the guide channel 11 along the length direction of the guide rail 16. Moving inwardly, the guide portion 151 also moves inwardly along the length direction of the guide rail 16 and compresses the return spring 17;

[0044] B. Secondly, adjust the position of the positioning pin 10 so that it is separated from a set of positioning holes 8 on the side close to the central axis of the bellows, and move to a set of positioning holes 8 on the side away from the central axis of the bellows and align with the positioning holes there. 8, and then the bellows to be connected and the connecting pipe body 1 are threaded unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com