Method and product application of biomass ammonification pyrolysis for co-production of ammoniated biomass charcoal, ammoniated bio-oil and ammonium salt

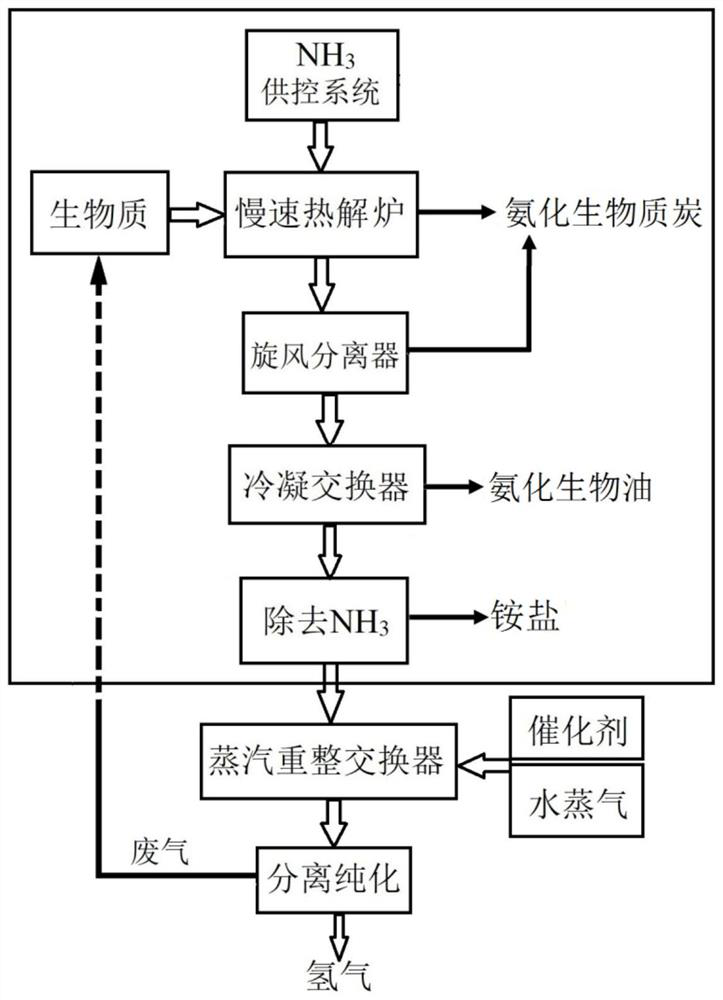

A technology of biomass charcoal and bio-oil, applied in the application, ammonium salt fertilizer, petroleum industry and other directions, can solve the problems of low nutrient and high acidity of bio-oil, and achieve the effect of improving the agricultural value and the potential of producing specific chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

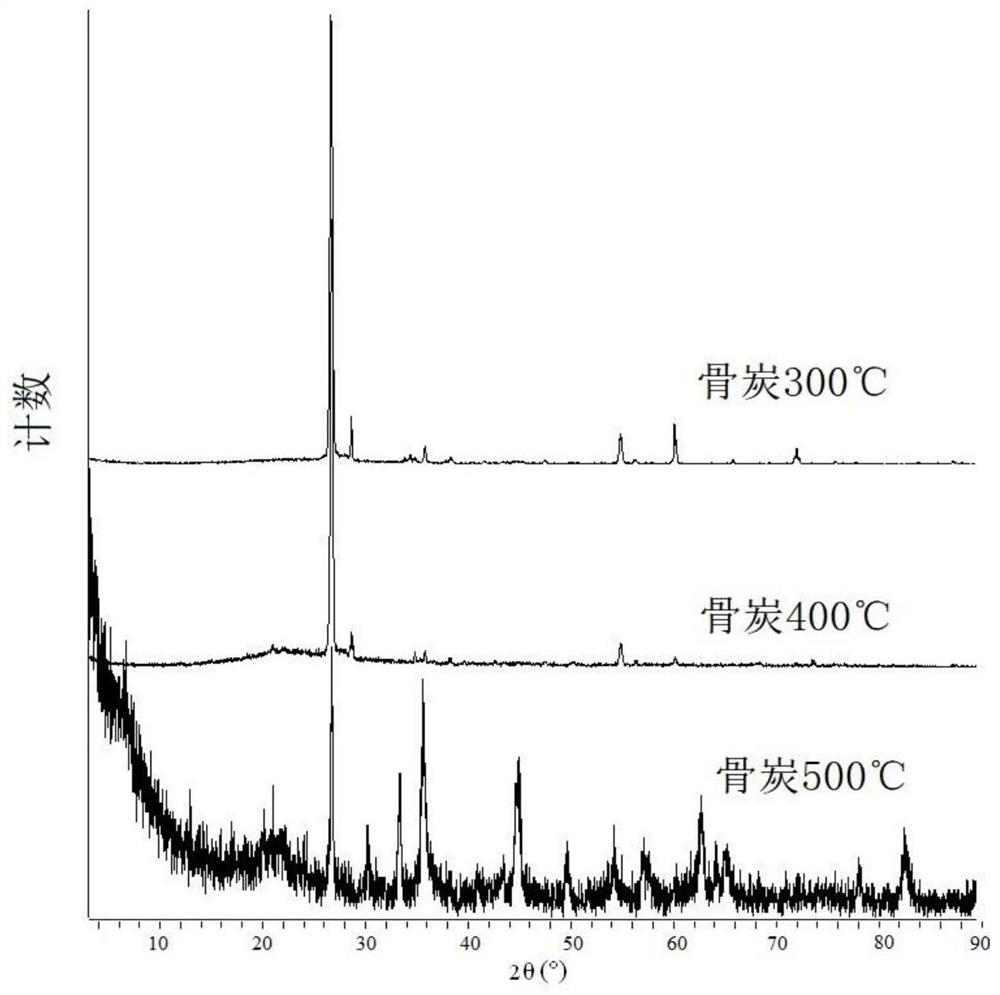

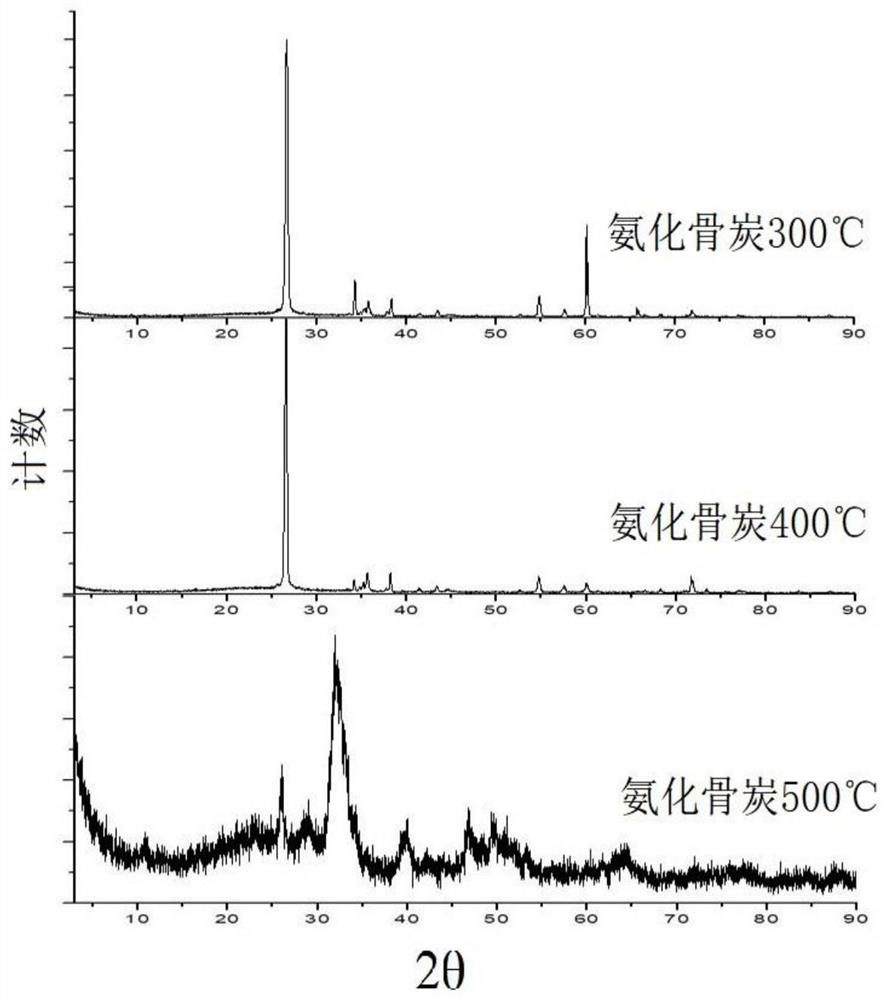

[0091] A method for producing bone char-based ammonium phosphate calcium fertilizer by ammonification and pyrolysis of bone meal, specifically comprising the following steps:

[0092] (1) Crushing animal bones to a particle size of ≤5 mm to obtain animal bone powder; wherein, the animal bones can be derived from any animal, for example, the animal bones are at least one of pig bones, bovine bones, and sheep bones;

[0093] (2) drying the animal bone powder obtained in step (1) to a water content of ≤10% by drying in the sun or drying equipment for pre-process drying;

[0094](3) The animal bone meal obtained in step (2) is metered into slow pyrolysis furnaces that have been preheated to process temperatures of 300°C, 400°C, and 500°C through a closed-air feeder (implemented in different examples), and simultaneously Ammonia gas heated to a temperature of 400° C. through the ammonia gas control supply system and the step-by-step heating pipeline is introduced into the slow pyro...

Embodiment 2

[0113] A method for producing ammoniated biochar, ammoniated bio-oil and fertilizer by slow-speed ammonification and pyrolysis of waste biomass of tobacco stalks and tendons (tobacco stalks and tendons particles), specifically comprising the following steps:

[0114] (1) crushing the waste biomass of tobacco stalks and tendons to the biomass particles of tobacco stalks and tendons smaller than 5 mm;

[0115] (2) drying the tobacco stalk and tendon biomass particles pulverized in step (1) to a moisture content of ≤10% through preheating and drying equipment;

[0116] (3) The tobacco stalk and tendon biomass particles dried in step (2) are sent into the biomass silo with a conveyor belt, and the tobacco stalk and tendon particles in the silo are sent to the screw feeding nozzle through a closed-air feeder, and are fed by the screw The device is metered and pushed into the rotary drum pyrolysis furnace which is preheated to the target temperature of 450°C; during the process of f...

Embodiment 3

[0127] A method for producing carbon-based slow-release compound fertilizer by slow pyrolysis of livestock and poultry manure in an ammonia atmosphere, specifically comprising the following steps:

[0128] (1) Livestock and poultry manure (pig manure) is dried by preheating drying equipment until the moisture content is ≤10%;

[0129] (2) The livestock and poultry manure with a water content lower than 10% obtained in step (1) can be directly sent into the pyrolysis reaction furnace through metering and feeding equipment, or after granulating biomass particles with a biomass granulator, and then Feed into the pyrolysis reaction furnace through metering and feeding equipment, and the loose livestock and poultry feces powder particles will increase their mass density after granulation, which is conducive to improving the amount of materials fed and pyrolysis efficiency.

[0130] (3) The livestock and poultry feces biomass granules obtained in step (2) are sent into the biomass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com