Preparation method and application of a core-shell type fluoropolymer nanoemulsion

A nanoemulsion and polymer technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased cost and difficulty in processing, and achieve good compatibility, easy access, and strong wetting reversal ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

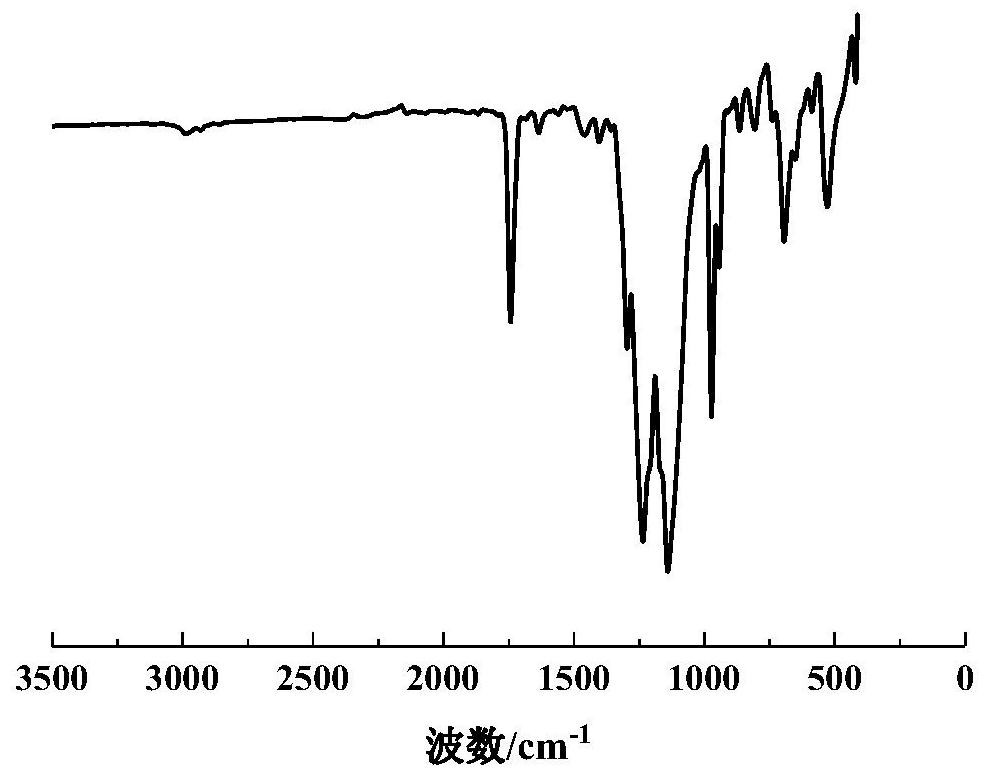

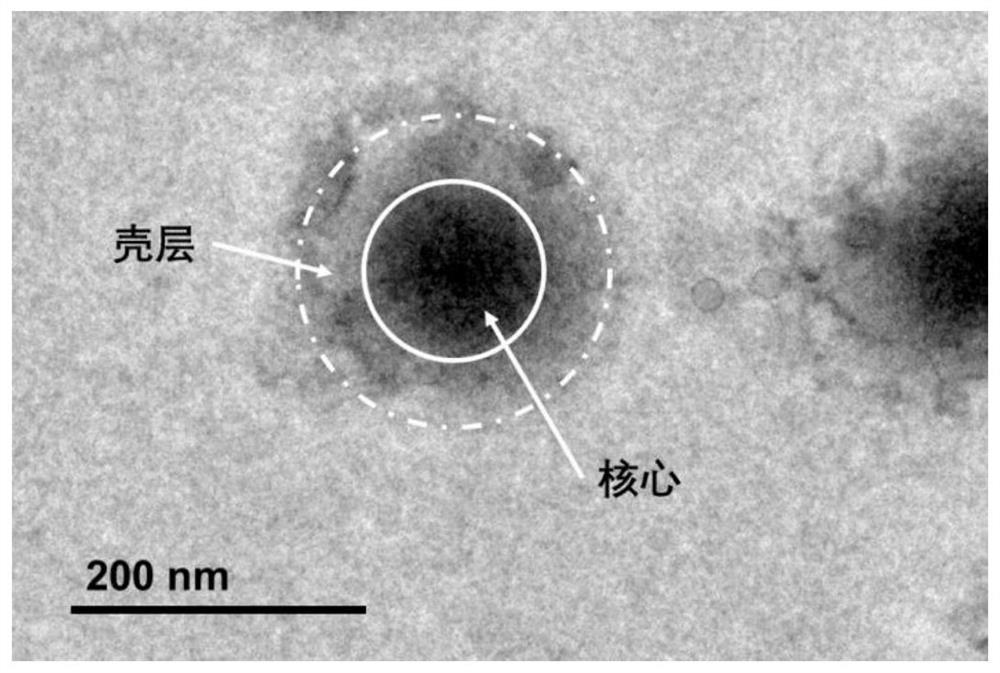

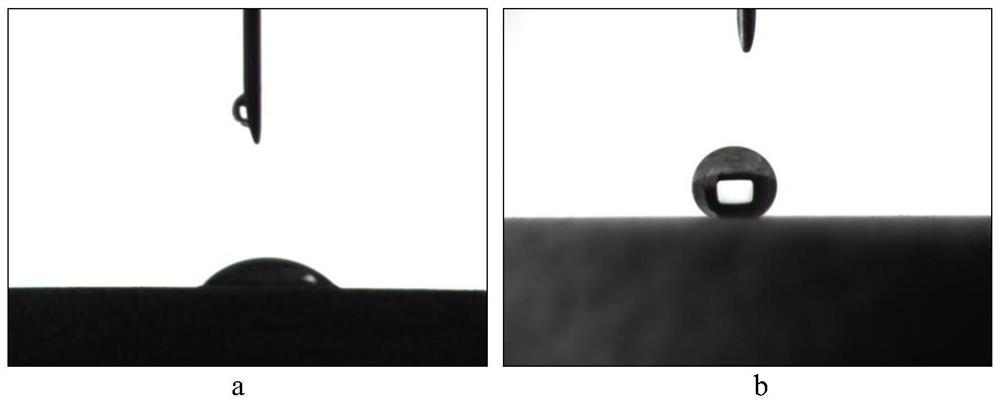

Method used

Image

Examples

Embodiment 1

[0044] In a 250mL three-necked flask with a reflux device and electromagnetic stirring, add 50mL distilled water and 1.0g sodium perfluorononenyloxybenzenesulfonate respectively, and after the solid is completely dissolved, add 1.0g (0.01mol) methyl methacrylate Ester (acrylic monomer) and 0.5g initiator azobisisobutyronitrile (AIBN) were dissolved in 50mL of N,N-dimethylformamide (DMF) and added to water, and heated to React at 80°C for 4 hours to obtain a prepolymer emulsion. After cooling to room temperature, add 6.0 g (0.015 mol) of dodecafluoroheptyl methacrylate (fluorine-containing monomer) into the prepolymer emulsion, ultrasonically emulsify at room temperature for 30 minutes, then raise the temperature to 80 ° C for 4 hours to obtain a white Emulsion products. The particle size distribution of the emulsion is 150-250nm; it is placed under normal temperature and pressure for 60 days without delamination.

Embodiment 2

[0046] The preparation method was as described in Example 1, except that the acrylic monomer was 1.4 g (0.01 mol) butyl methacrylate. The obtained product emulsion has a particle size distribution of 200-250nm; it is placed under normal temperature and pressure for 60 days without delamination.

Embodiment 3

[0048] The preparation method was as described in Example 1, except that the fluorine-containing monomer was 6.5 g (0.015 mol) of 2-(perfluorohexyl) ethyl methacrylate. The obtained product emulsion has a particle size distribution of 150-250nm; it is placed under normal temperature and pressure for 60 days without delamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com