Central filling pipe for soft package packaging machine

A technology of packaging machinery and filling tubes, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of inability to reach filling capacity and inability to fully unfold, reduce the hidden danger of cutting the film, and ensure full unfolding , to ensure the effect of filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

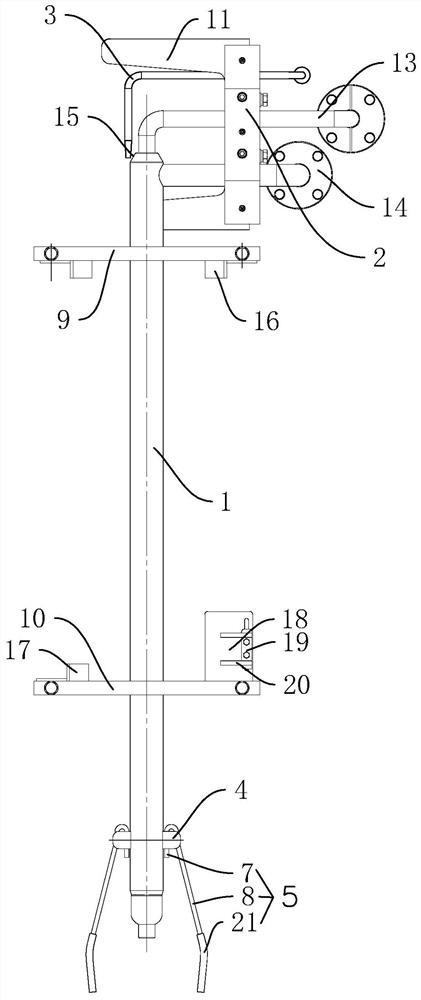

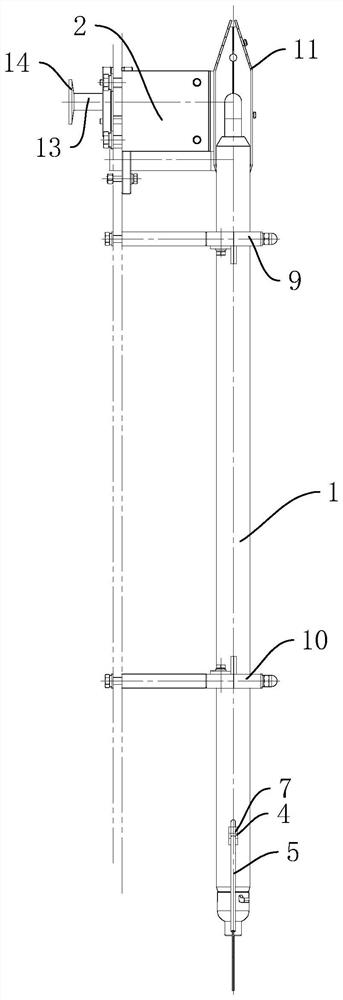

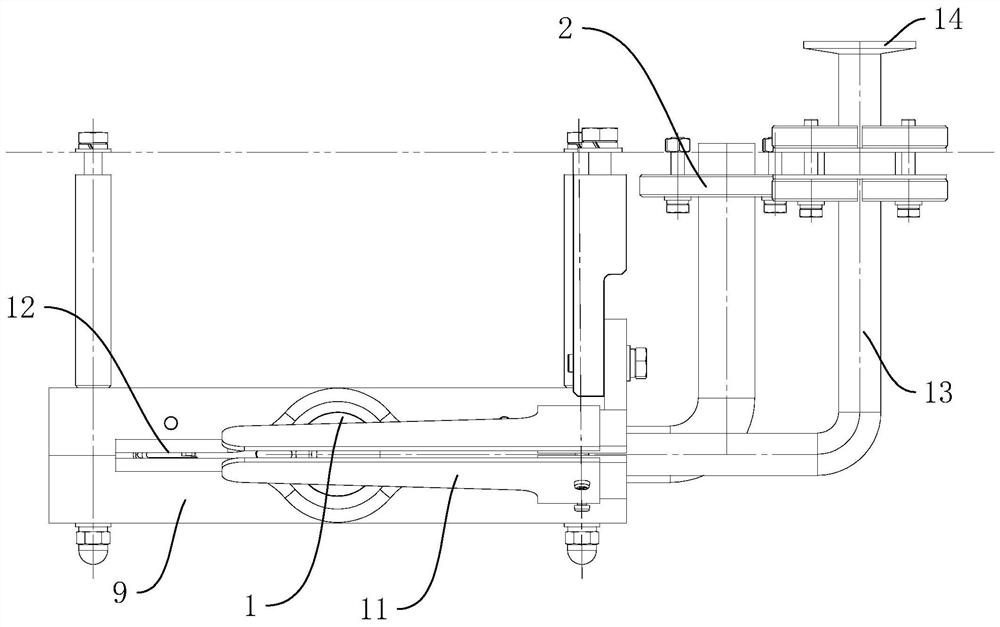

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Center filling tubes for flexible packaging machinery such as figure 1 , figure 2 As shown, it includes a vertical pipeline 1, the top of the vertical pipeline 1 is connected with an upper installation plate 2, and the upper installation plate 2 is clamped and fixed with a hydrogen peroxide atomizing nozzle 3, and the bottom of the vertical pipeline 1 is provided with a support package assembly, and the support package assembly It includes two lugs 4 symmetrically arranged on the outer wall of the vertical pipe 1, and a strut 5 with elastic deformation capability. The strut 5 has a plug-in section 6 inserted into the lug 4, and the lug 4 is processed and formed with a clamping mouth 7 , The strut 5 has a flared section 8, and the flared section 8 is tight against the inside of the jaw 7.

[0028] When the application is working normally, the film mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com