Z-shaped compression-torsion metamaterial structure

A technology of metamaterials and beam structures, applied in the field of metamaterials, can solve problems such as insufficient stability of compression and torsion effects, high manufacturing difficulty, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Use a 3D printer to print, the material used is TPU95A, and the water-soluble support material used is PVA.

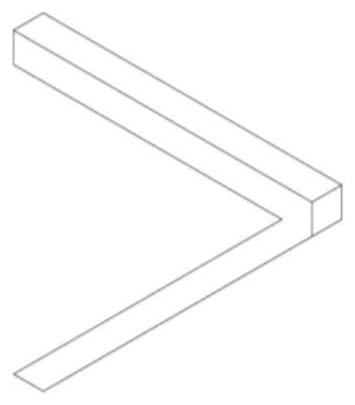

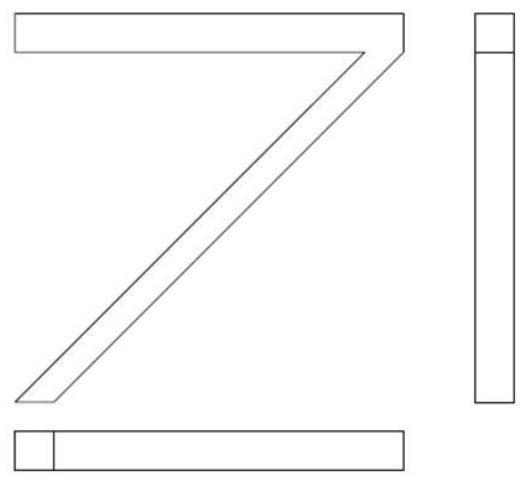

[0039] Embodiment 1, in-plane beam structure such as figure 2 As shown, its main structure is connected by 2 straight beams at 45°, the width of the short beams is 10mm, the width of the long beams (ie oblique beams) is about 7mm, and the thickness is 10mm.

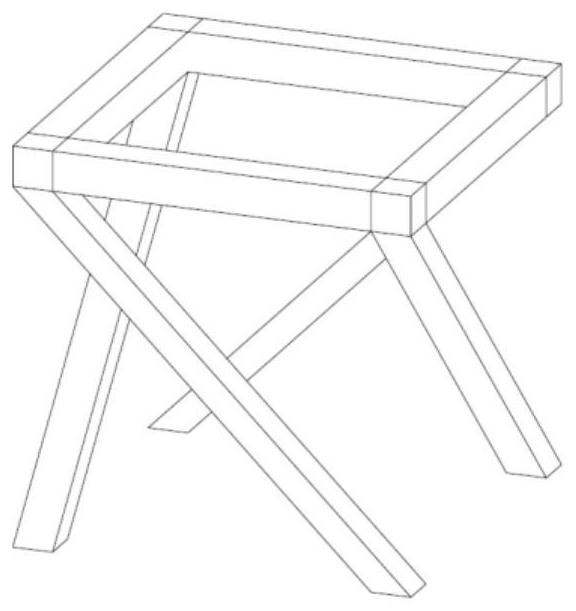

[0040] In embodiment 1, cell such as Figure 4 As shown, the cell is a square tube composed of four in-plane beams perpendicular to each other.

[0041] In Example 1, 1×1×8 is stacked as Figure 9 As shown, this stack is a structure of 8 cells arranged in 1 row, 1 column, and 8 layers.

[0042] After the printing is completed, soak the printed parts in water, and replace the clean water when the water becomes turbid until the PVA support completely disappears, and then dry it.

[0043] Such as Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, the 1×1×8 stacked...

Embodiment 2

[0045] The cell size in embodiment 2 is the same as that in embodiment 1, and the manufacturing method is also the same as in embodiment 1, so details are not repeated here.

[0046] In Example 2, 2×2×8 are stacked as Figure 16 As shown, this stack is a structure of 32 cells arranged in 2 rows, 2 columns, and 8 layers.

[0047] Such as Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 and Figure 21 As shown, the 2×2×8 stacked compression-torsion superstructure undergoes obvious torsion after compression, as shown by Figure 18 , Figure 19 The measurable pressing distance is about 125mm, and the strain is 15.6%, which can be determined by Figure 22 The measurable torsion angle is about 18°, the radian is 0.314, the calculated angle-to-strain ratio is 1.15° / %, and the radian ratio is 0.02 / %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com