Nickel chrome wire defective segment detection device and detection method

A detection device, nickel-chromium wire technology, applied in the direction of material magnetic variables, etc., can solve problems such as unfavorable practical use, instability, broken segments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

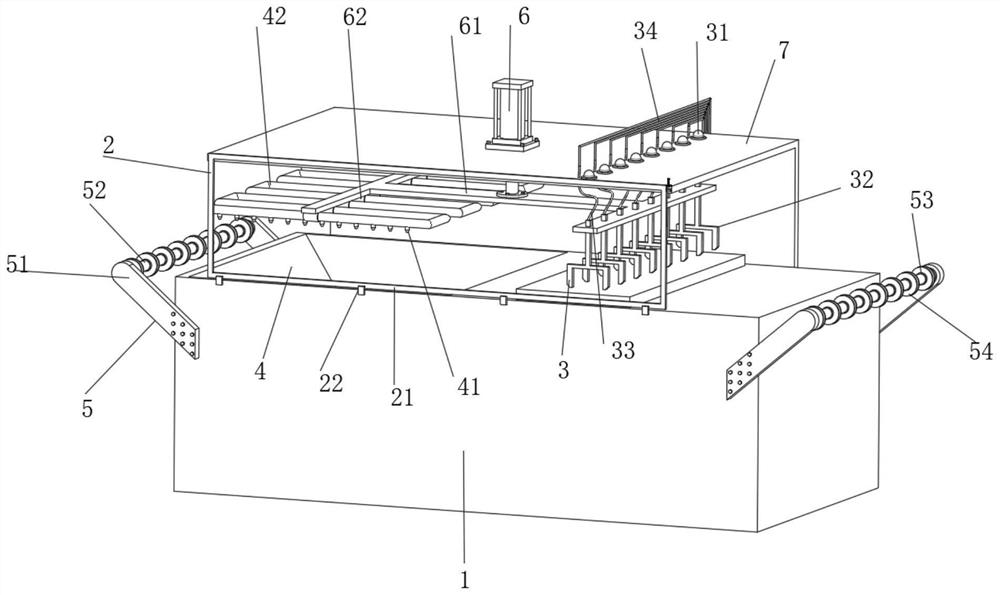

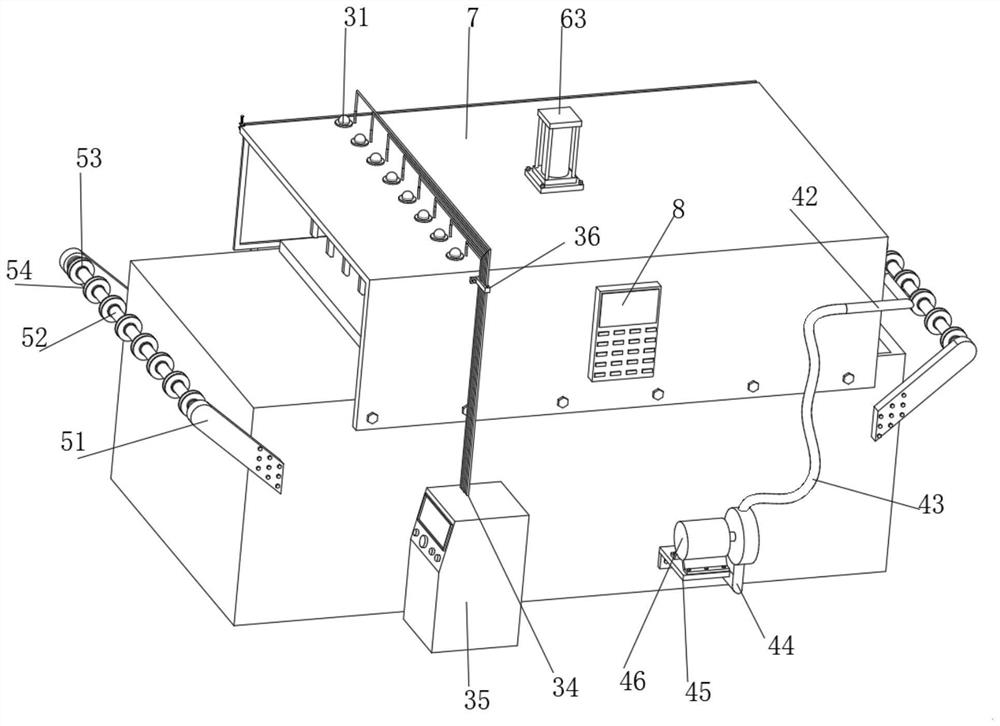

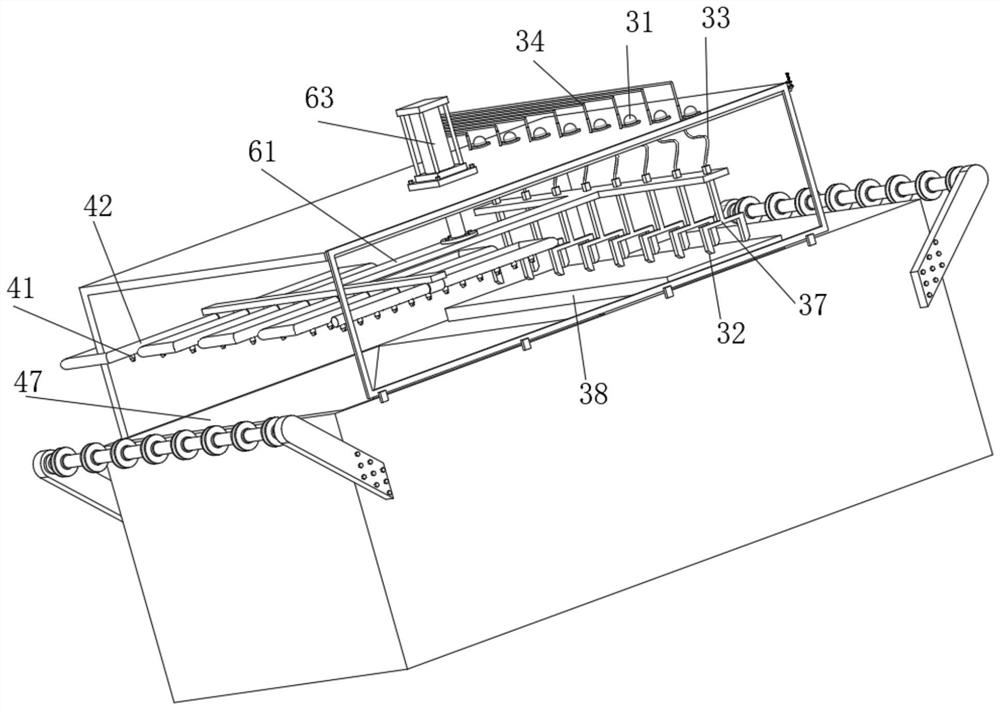

[0043] Such as figure 1 , 2As shown, a nickel-chromium wire bad section detection device includes a detection box 1, the two ends of the side wall of the detection box 1 are connected with a guide structure 5 for nickel-chromium wire guidance, and the guide structure 5 includes a support swash plate 51, a round rod 52 , bearing 53 and guide wheel 54, the inner wall upper end of support swash plate 51 is fixedly connected with round bar 52, and round bar 52 is evenly fixedly connected with bearing 53, and the outer ring of bearing 53 is fixedly connected with guide wheel 54, and the arc shape of guide wheel 54 The groove is movably connected with the nickel-chromium wire, and the bottom of the support slant plate 51 is fixedly installed on the side wall of the detection box 1 by bolts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com